Grouting device for coal mine water disaster preventing and treating

A grouting device and disaster technology, which is applied to cement mixing devices, clay preparation devices, mining equipment, etc., can solve the problems of no mixing bucket, insufficient pump pressure, and complicated multiple motors, so as to improve prevention and control capabilities and simplify switching. Convenient and avoid the effect of bonding and solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

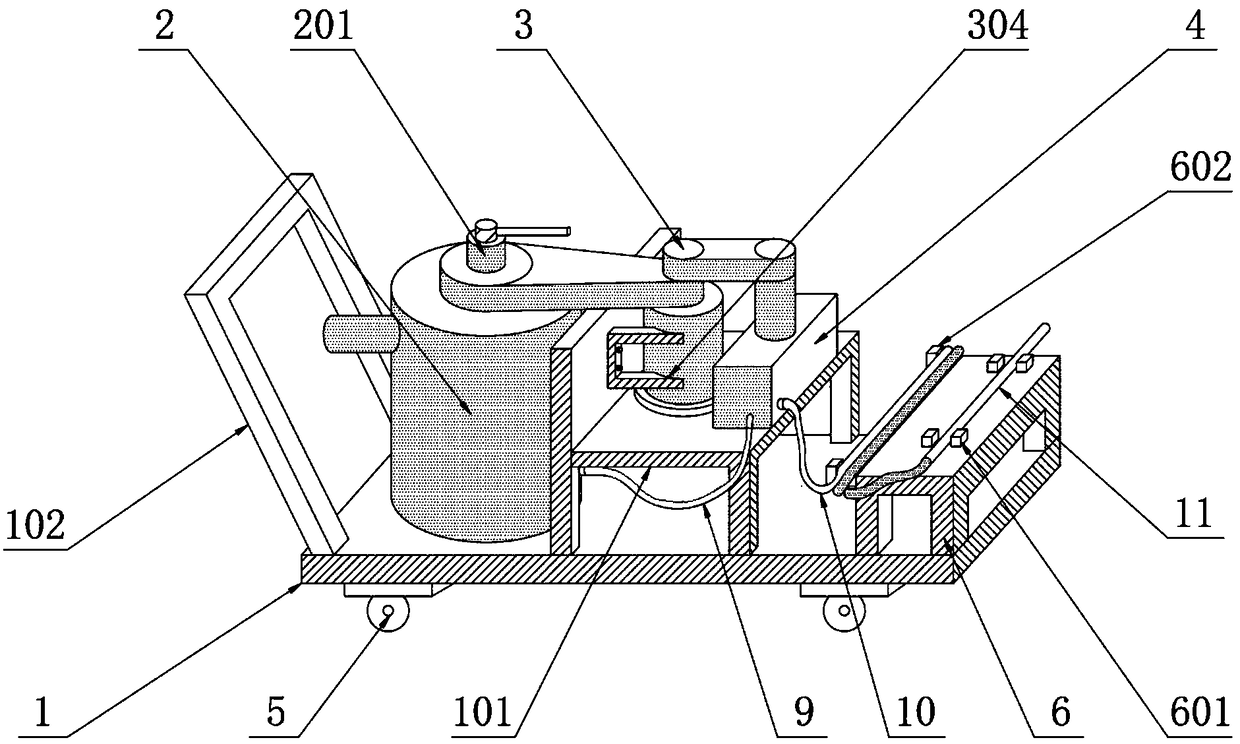

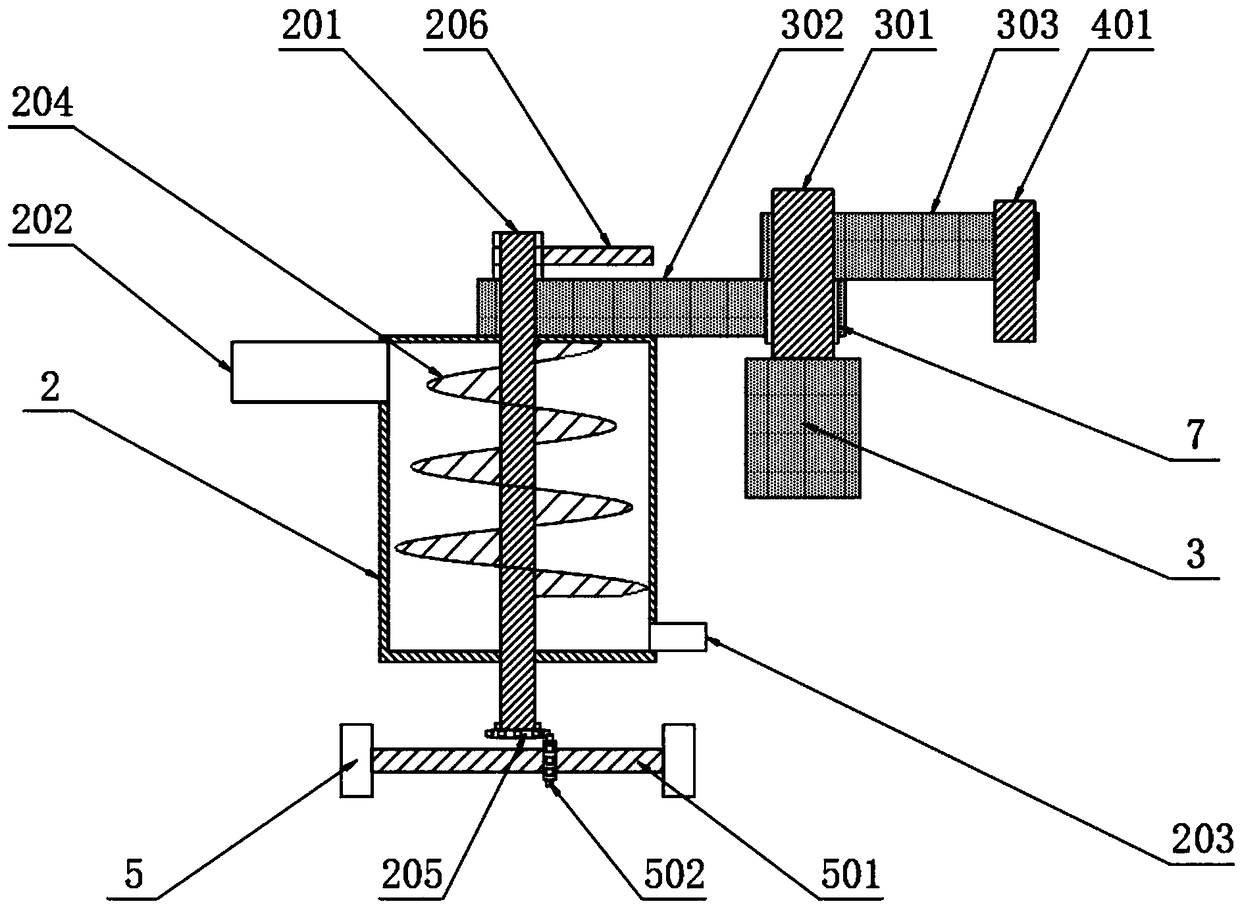

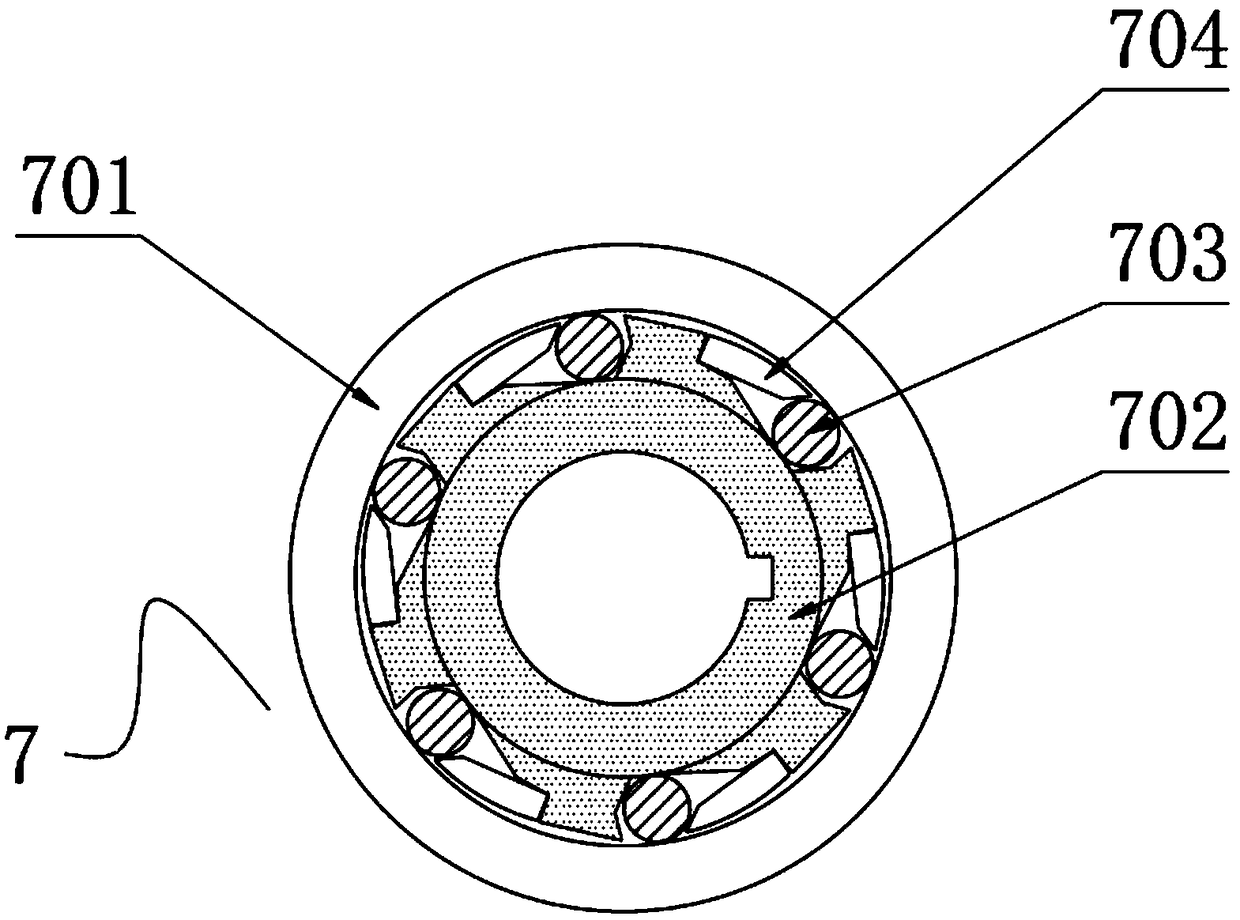

[0032] see Figure 1~4 , in an embodiment of the present invention, a coal mine water disaster prevention and control grouting device, including a bottom plate 1, a mixing tank 2, a motor 3, a hydraulic pump 4 and a grouting head assembly 11, the bottom of the bottom plate 1 is provided with a roller 5, the The first rotating shaft 201 extending vertically is arranged in the mixing barrel 2, and the stirring blade 204 is arranged on the first rotating shaft 201. It is characterized in that, the upper end of the first rotating shaft 201 protrudes from the mixing barrel 2, and The upper end of the first rotating shaft 201 is connected to the output shaft of the electric motor 3 by a transmission switching assembly, and the output shaft of the electric motor 3 is connected to the hydraulic pump 4 in order to drive the hydraulic pump to The grouting device provides power; the transmission switching assembly can make the motor 3 drive the first rotating shaft 201 in the mixing buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com