Combined reinforcement structure for solving cracked steel bridge deck by additionally arranging fiber-reinforced layer

A fiber-reinforced and reinforced structure technology, applied in the direction of bridge reinforcement, erection/assembly of bridges, bridges, etc., can solve the problems of increasing bridge self-weight, complicated construction procedures, and reducing bearing capacity, so as to reduce construction difficulty, avoid continuous expansion, and ensure tight bond effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

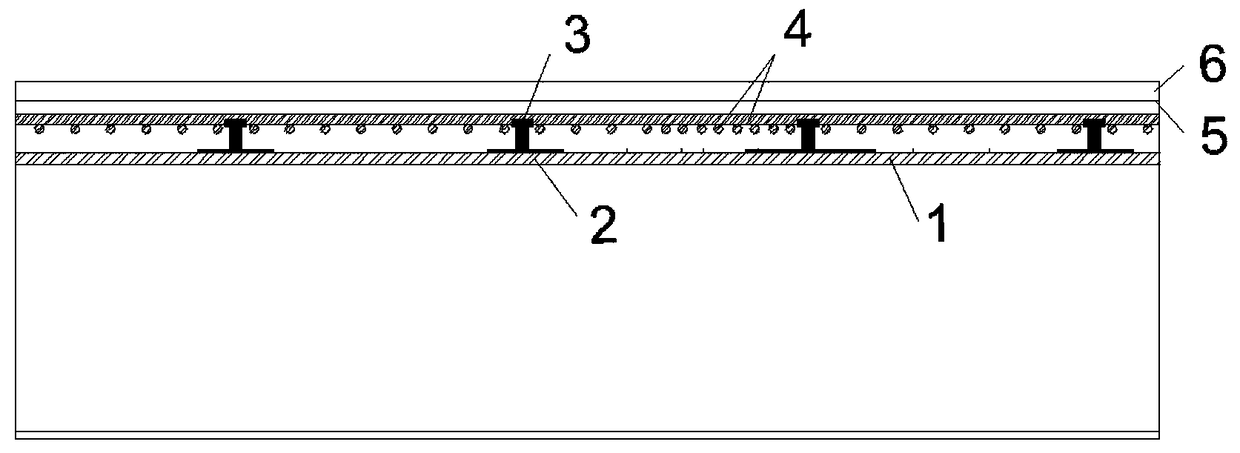

[0043] Example 1, the present invention includes a fatigue cracked steel bridge deck, fiber reinforced FRP material, metal lath, shear connectors and concrete layers.

[0044] The studs can be arranged on the fatigue-cracked steel bridge deck according to the actual situation. If the studs are arranged, the spacing should be 100-300 mm, and the FRP material can be closely adhered to the steel bridge deck by using cementing materials.

[0045] The metal slats are firmly linked with the steel bridge deck through a reliable connection, and shear keys are arranged on the metal slats, and then two or more layers of steel mesh are arranged, the spacing of the steel bars is to be determined, and finally the concrete layer is poured, see Figure 1 to Figure 2 .

Embodiment 2

[0046] Embodiment 2, the present invention may also include a fatigue cracked steel bridge deck, a fiber-reinforced composite material layer, a shear connector, a steel mesh and a concrete layer, the fiber-reinforced composite material layer is provided with a shear connector, and the fiber The reinforced composite material layer is laid to the cracked part of the fatigue-cracked steel bridge deck, which is tightly adhered to the steel bridge deck by epoxy resin glue, the steel mesh is placed on the fatigue-cracked steel bridge deck, and the concrete layer is poured to the fatigue-cracked steel bridge deck, and cover the shear connectors, reinforcement mesh and fatigue-cracked steel bridge deck, see Figure 1 to Figure 2 , and the rest are the same as the combination of any of the above embodiments or two or more embodiments.

Embodiment 3

[0047] Embodiment 3, the present invention is provided with shear connectors on the fatigue cracked steel bridge deck, the fiber reinforced composite material layer is laid to the cracked part of the fatigue cracked steel bridge deck, and the steel mesh is placed on the fatigue cracked steel bridge deck Above, the concrete layer is poured on the fatigue cracked steel bridge deck, and the covering shear connectors, steel mesh are connected with the fatigue cracked steel bridge deck, see Figure 1 to Figure 2 , and the rest are the same as the combination of any of the above embodiments or two or more embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com