Intelligentized cotton yarn twisting-doubling production line and cotton yarn twisting-doubling process in textile industry

A technology of cotton yarn and textile industry, which is applied in the field of cotton yarn intelligent twisting production line and cotton yarn twisting process in the textile industry, which can solve the problems of low work efficiency, high labor intensity, and long time-consuming cotton yarn, so as to save time , high work efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

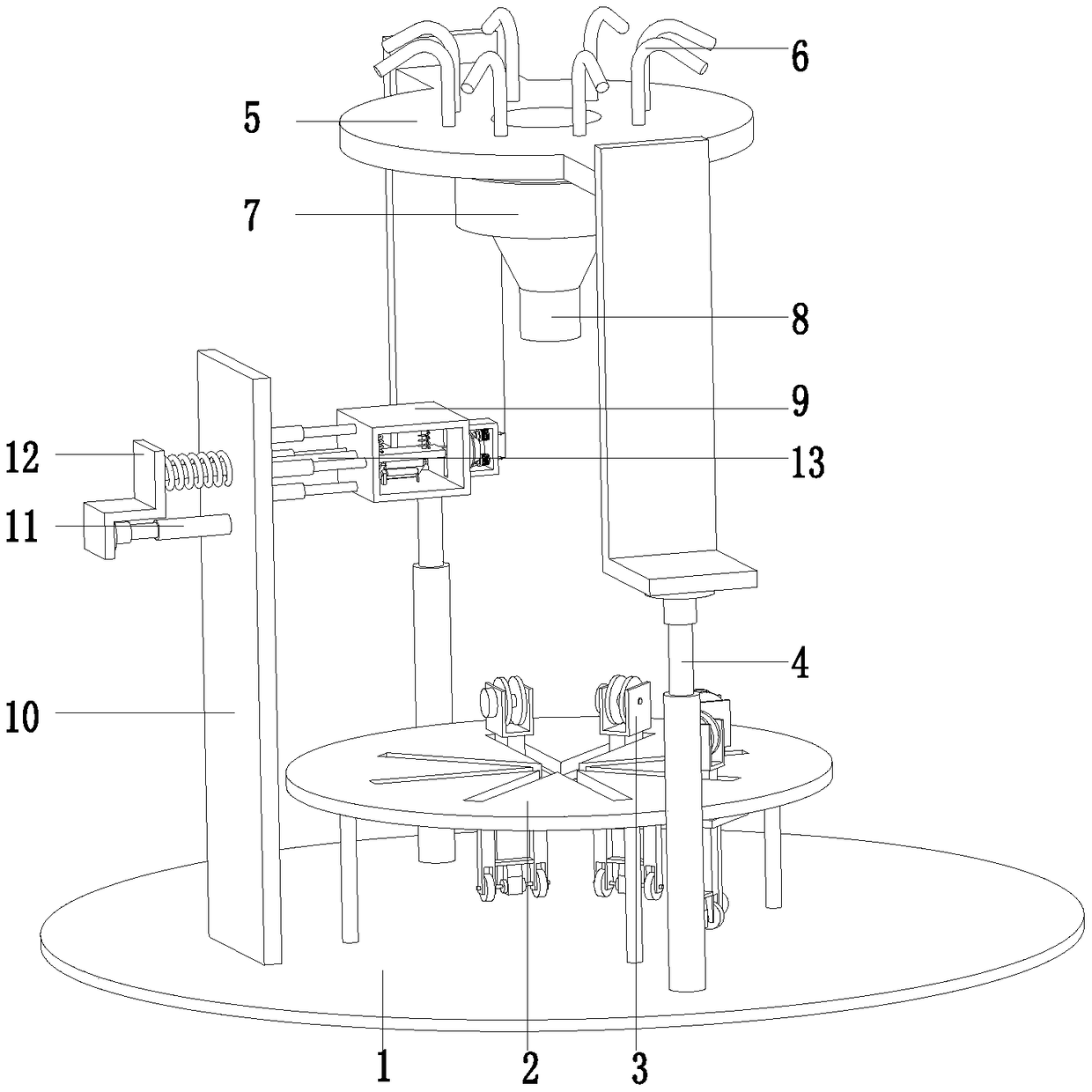

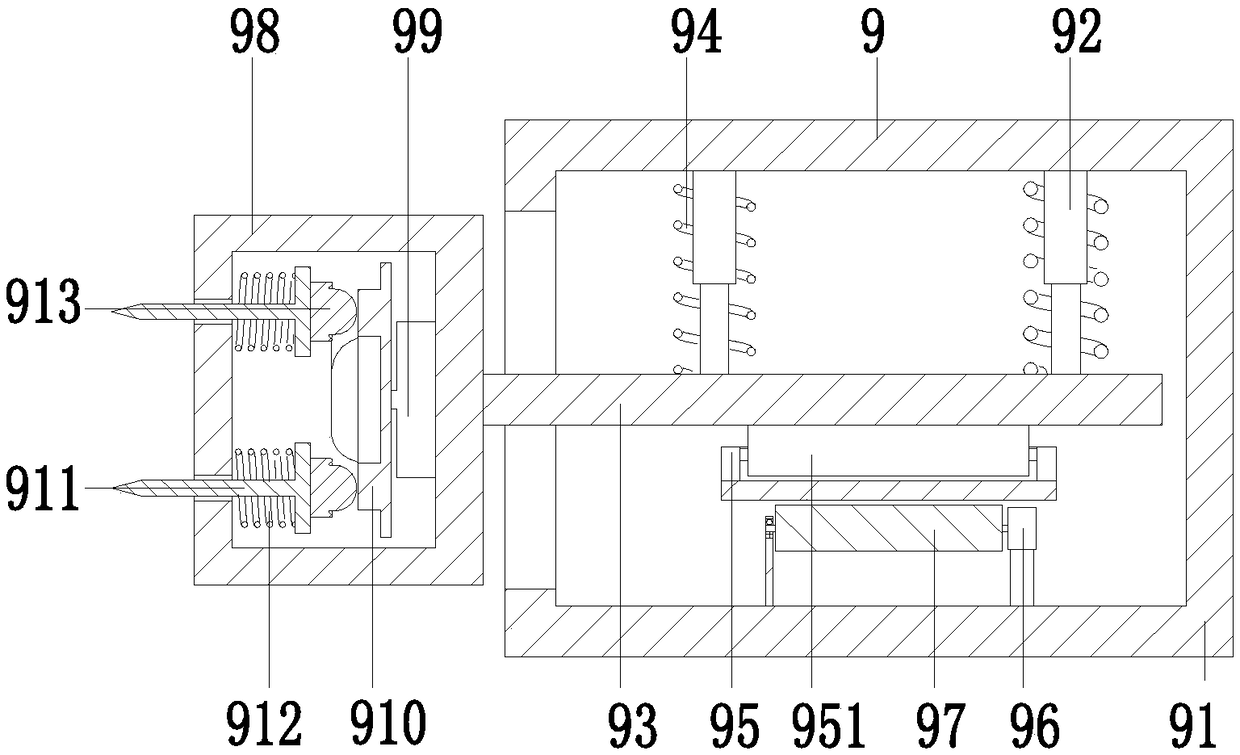

[0019] Such as Figure 1 to Figure 3 As shown, an intelligent twisting production line for cotton yarn in the textile industry includes a base plate 1, a support operation plate 2 is installed in the middle of the base plate 1, and a work limit groove is uniformly arranged on the support work plate 2, and a work limit groove is arranged in the work limit groove. The operation delivery mechanism 3 is equipped with an adjustable lifting cylinder 4 on the base plate 1, and the top of the adjustable lifting cylinder 4 is equipped with a lifting control frame 5 through a flange. The middle part of the lifting control frame 5 is provided with a working groove. The circumferential direction of the work tank is evenly provided with fixed hooks 6, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com