Preparation method and application of sulfur and nitrogen co-doped carbon quantum dots

A technology of carbon quantum dots and co-doping, applied in chemical instruments and methods, nanotechnology for materials and surface science, luminescent materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing carbon quantum dots co-doped with sulfur and nitrogen, comprising the following steps:

[0028] Mix phenothiazine, sodium nitrite, dichloromethane and acetic acid for nitration reaction to obtain 3,7-dinitrophenothiazine;

[0029] The 3,7-dinitrophenothiazine and lye are mixed, followed by hydrothermal reaction and dialysis to obtain carbon quantum dots co-doped with sulfur and nitrogen.

[0030] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0031] The invention mixes phenothiazine, sodium nitrite, dichloromethane and acetic acid for nitration reaction to obtain 3,7-dinitrophenothiazine. In the present invention, the phenothiazine is simultaneously used as a nitrogen source and a sulfur source; the sodium nitrite is a nitrogen source; the dichloromethane is a solvent for phenothiazine; and the acetic acid is a s...

Embodiment 1

[0061] Synthesis of 3,7-dinitrophenothiazine:

[0062]

[0063] Under the condition of stirring, in the mixture of 20.00g phenothiazine (100mmol), 100mL dichloromethane and 40mL acetic acid, slowly add 20.00g sodium nitrite (300mmol), after stirring at room temperature for 1h, then add 100mL dichloromethane, 40mL of acetic acid and 20.00g of sodium nitrite were reacted for 1.5h, and a large amount of solids were formed; then 120mL of dilute acetic acid solution was added to the system, and the stirring was continued for 2h, followed by suction filtration, and washing with ethanol and water three times. Then the obtained solid was dissolved in DMF at 100° C., filtered while hot, and the filter cake was the product. The filter cake was washed with ethanol and dried to obtain purple-red 3,7-dinitrophenothiazine (yield 86%). 1 HNMR (400MHz; DMSO-d 6 ): 6.69 (d, J=4Hz, 2H), 7.70 (s, 2H), 7.82 (d, J=4Hz, 2H). HRMS(ESI)m / zC 12 h 8 N 3 o 4 S + (M+H) + Calculated: 290.0230, ...

Embodiment 2

[0069] Synthesis Reference Example 1 of 3,7-dinitrophenothiazine;

[0070] Synthesis of sulfur and nitrogen co-doped carbon quantum dots:

[0071] Under the condition of ultrasound, 0.3g of 3,7-dinitrophenothiazine was dispersed in 60mL of 1mol / L ammonia solution, kept for 2h to obtain a suspension, and reacted at 200°C for 12h. After the reaction is completed, cool to room temperature, and filter the reaction solution with a filter membrane with a pore size of 0.22 microns to remove large particles of water-insoluble carbon materials and some unreacted raw materials. Concentrate the filtrate and perform dialysis with a dialysis bag with a molecular weight cut-off of 500-1000 to remove sodium salts and non-carbonized small molecules, and vacuum-dry to obtain sulfur-nitrogen doped carbon quantum dots, which are designated as D-2. The shape of D-2 is approximately spherical, the particle size distribution range is 1.5-4nm, and the average particle size is 3.1nm;

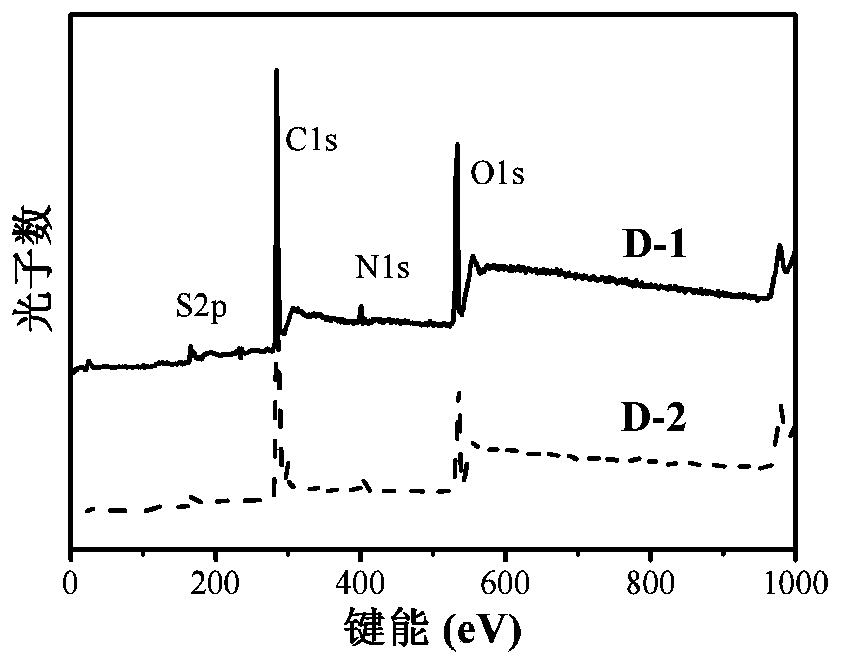

[0072] Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com