Automatic organic waste treatment system

A technology for processing systems and organic wastes, applied in organic fertilizers, excretion of fertilizers, climate change adaptation, etc., can solve the problems of low degree of automation, high labor and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

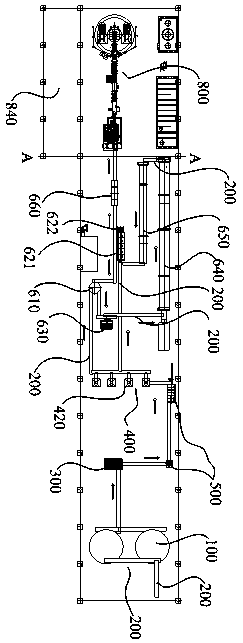

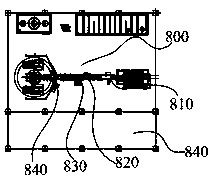

[0022] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention proposes an embodiment of an automatic organic waste treatment system. Refer to Figure 1-Figure 4 As shown, it includes: fermenter 100, fermenter 100 is mainly used to realize fermenting the feces of animals and livestock, and fermenter 100 includes a discharge layer, a fermentation layer, a feeding layer and a steam generation layer, wherein the fermentation layer accounts for the total The volume is about 80%, so that the input fertilizer can maintain enough space in the fierce reaction and change.

[0023] The fermentation principle of the fermenter 100 is: add oxygen to organic waste food waste, sewer sludge, livestock manure, and livestock waste, so that during the stirring process, the aerobic microorganisms in the waste need oxygen to survive better. Microorganisms achieve optimal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com