Low-temperature printing platform and low-temperature printing platform blanking detection method

A printing platform and printing material technology, which is applied in the field of 3D printing, can solve the problems that it is impossible to actually determine whether the nozzle has been extruded with material, and the material has leaked to print, and achieve the effects of preventing missing printing, improving efficiency, and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

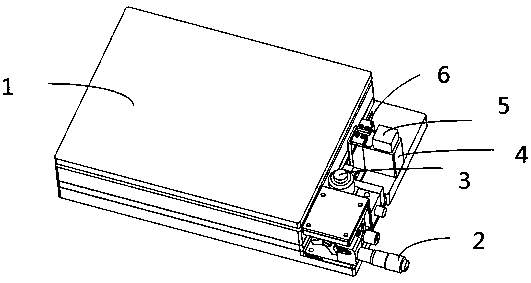

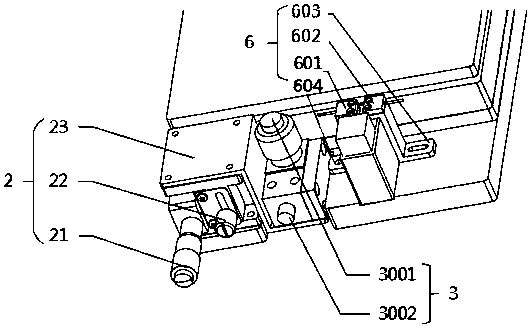

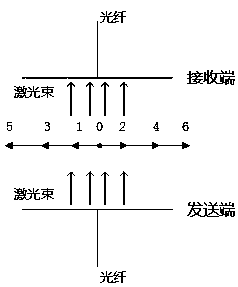

[0053] figure 1 , 2 Shown is a schematic diagram of the structure of the low-temperature printing platform in this embodiment. The low-temperature printing platform can perform blanking detection on the pre-extrusion operation of the needle tip of the nozzle, and includes a blanking detection module 6 and a controller. The controller and the blanking detection The module is connected in communication, and the described falling material detection module 6 includes a sensor, and the sensor has a material falling identification area, and the material extruded by the needle tip of the nozzle can pass through the material falling identification area of the sensor in the material falling detection module for material falling Detection, the controller can judge whether there is printing material extruded according to the open circuit signal in the blanking identification area.

[0054] In this embodiment, the sensor is an optical sensor, and the blanking identification area is an ...

Embodiment 2

[0065] Other parts of this embodiment are the same as Embodiment 1, the difference is that in this embodiment, the sensor is an image sensor, and the falling material recognition area is an image recognition area. material situation.

Embodiment 3

[0067] Other parts of this embodiment are the same as in Embodiment 1, such as Figure 6 As shown, the low-temperature printing platform further includes a blanking storage module 4, which is arranged below the optical sensor of the blanking detection module 6 and can store dropped blanking.

[0068] The blanking storage module 4 may include a storage box main body 41, a magnetic attraction 42 and a storage box slot 43, and the storage box main body 41 is located below the transmitting end 601 and the receiving end 602 and is located on the first fixing bracket 603 Between the second fixing bracket 604, the storage box slot 43 can limit the position of the storage box main body 41, and the magnetic attraction 42 is located in the storage box slot 43 and can attract and fix the storage box main body 41 on the Storage box card slot 43.

[0069] Specifically, the blanking storage module 4 is arranged on the platform substrate 1001, and the position of the platform substrate 1001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com