Material feeding device for quartz sand crusher

A technology of crusher and quartz sand, which is applied in the direction of grain processing, etc., can solve the problems of time-consuming and laborious, unable to realize automatic continuous feeding, etc., and achieve the effect of protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

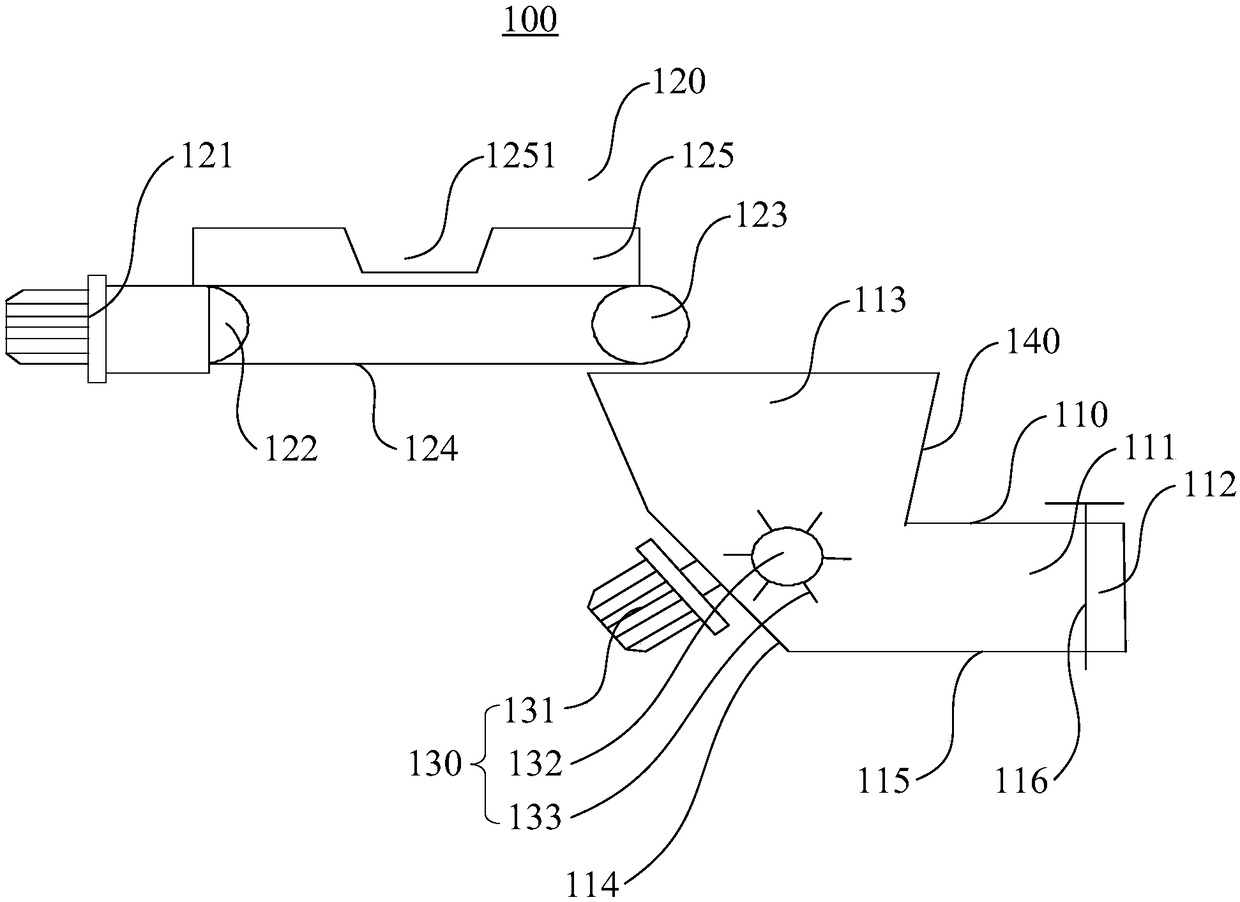

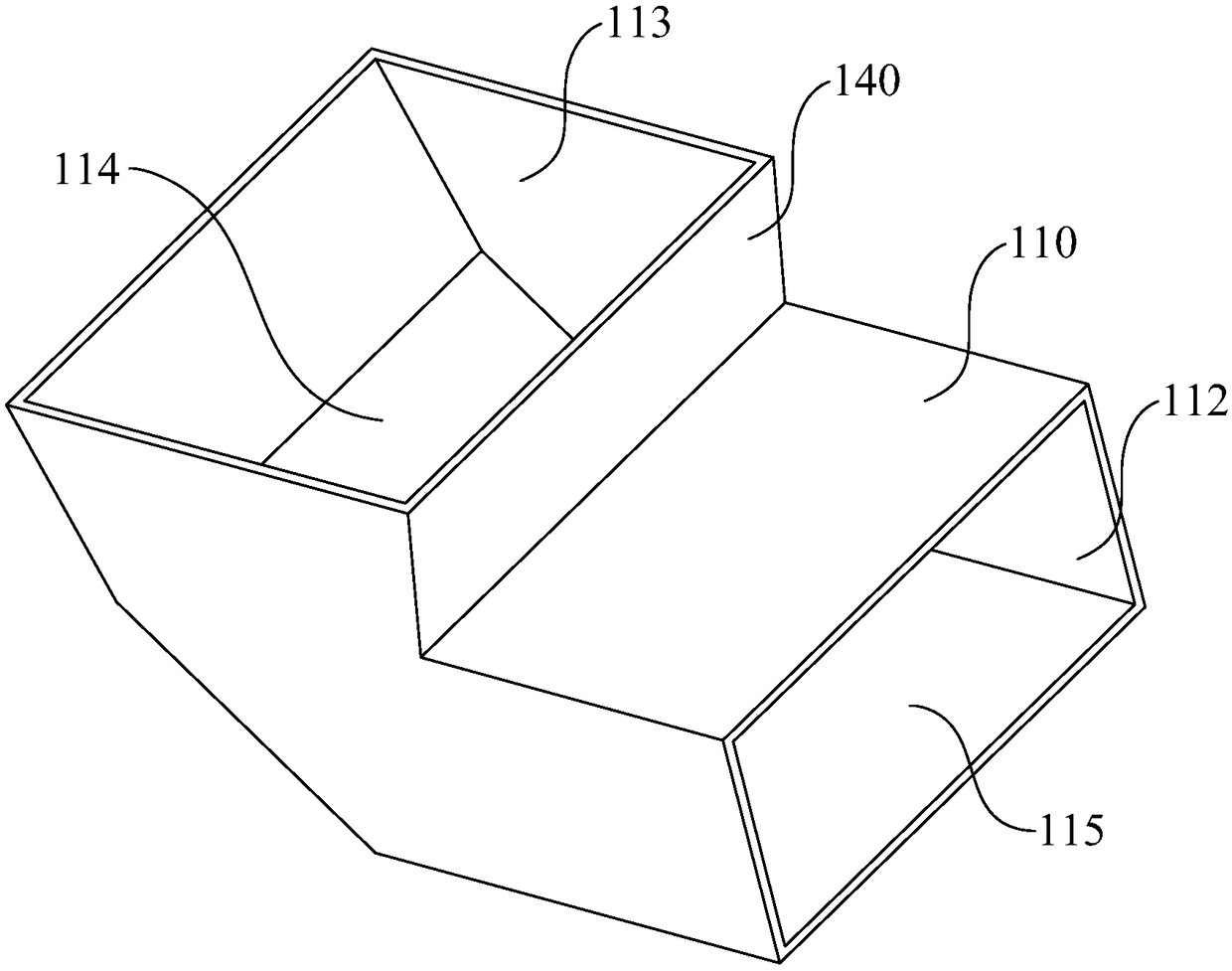

[0022] The present invention is specifically described below in conjunction with accompanying drawing:

[0023] Please refer to figure 1 and figure 2 , a feeding device 100 for a quartz sand crusher, comprising: a feeding box 111, the feeding box 111 is provided with a feeding chamber 111 and a feeding port 113 and a feeding port 112 communicating with the feeding chamber 111; Mechanism 120, the output end of conveying mechanism 120 is located at feed inlet 113, and conveying mechanism 120 is used to convey quartz raw material to feeding box 111; Above, the pulling mechanism 130 is used to pull the quartz raw material out from the outlet 112 .

[0024] The feeding device 100 of the above-mentioned quartz sand crusher, through the conveying mechanism 120, makes the quartz raw material rush into the feeding port 113 into the feeding chamber 111, and then transports the quartz raw material to the crusher through the discharging port 112, so, The automatic and continuous feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com