Net cage with automatic cleaning and feeding functions

An automatic cleaning and cage technology, applied in the field of aquaculture equipment, can solve the problems of affecting reproduction, increase of microorganisms, high labor intensity, etc., and achieve the effects of reducing the cost of breeding, improving the breeding environment, and high transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

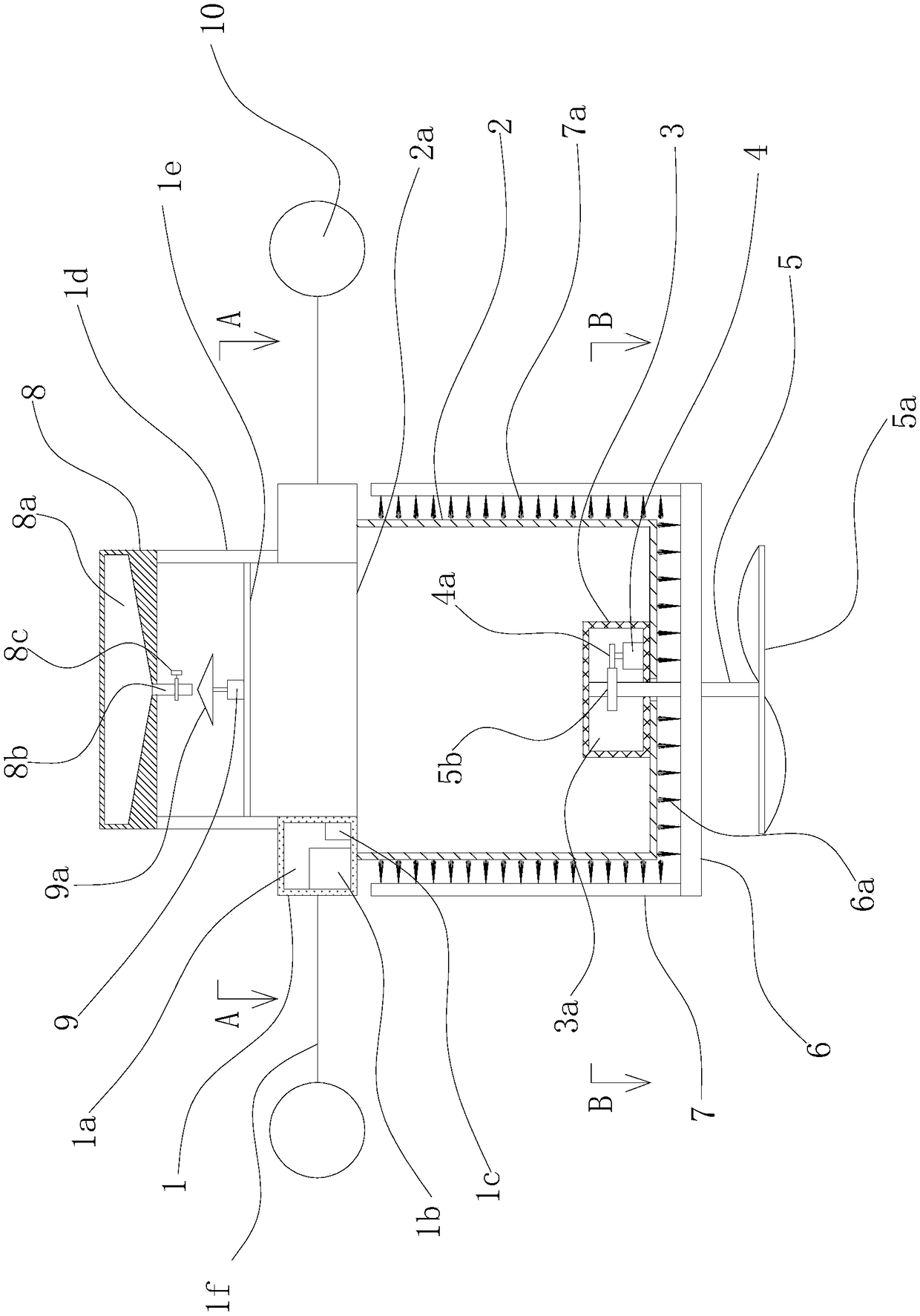

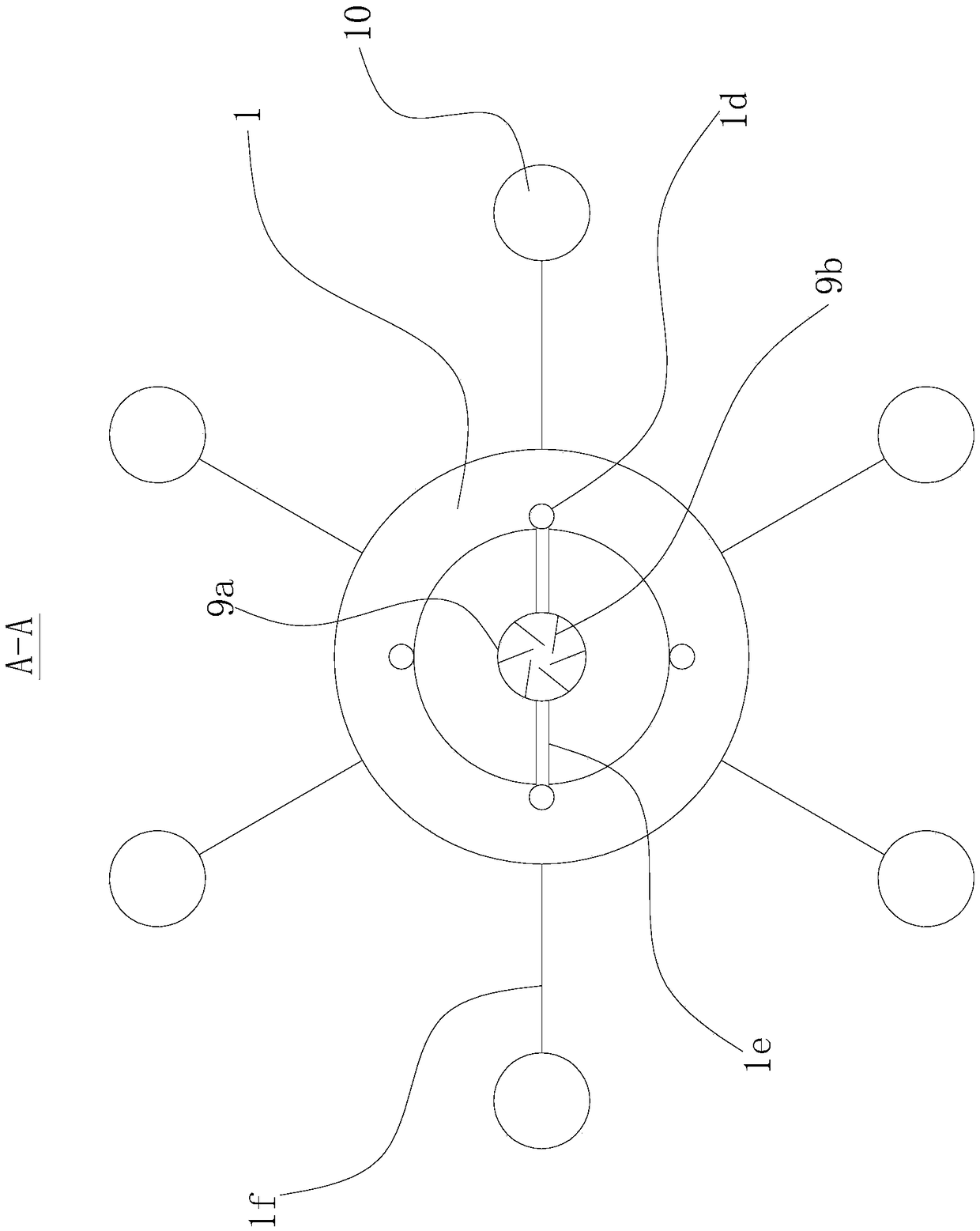

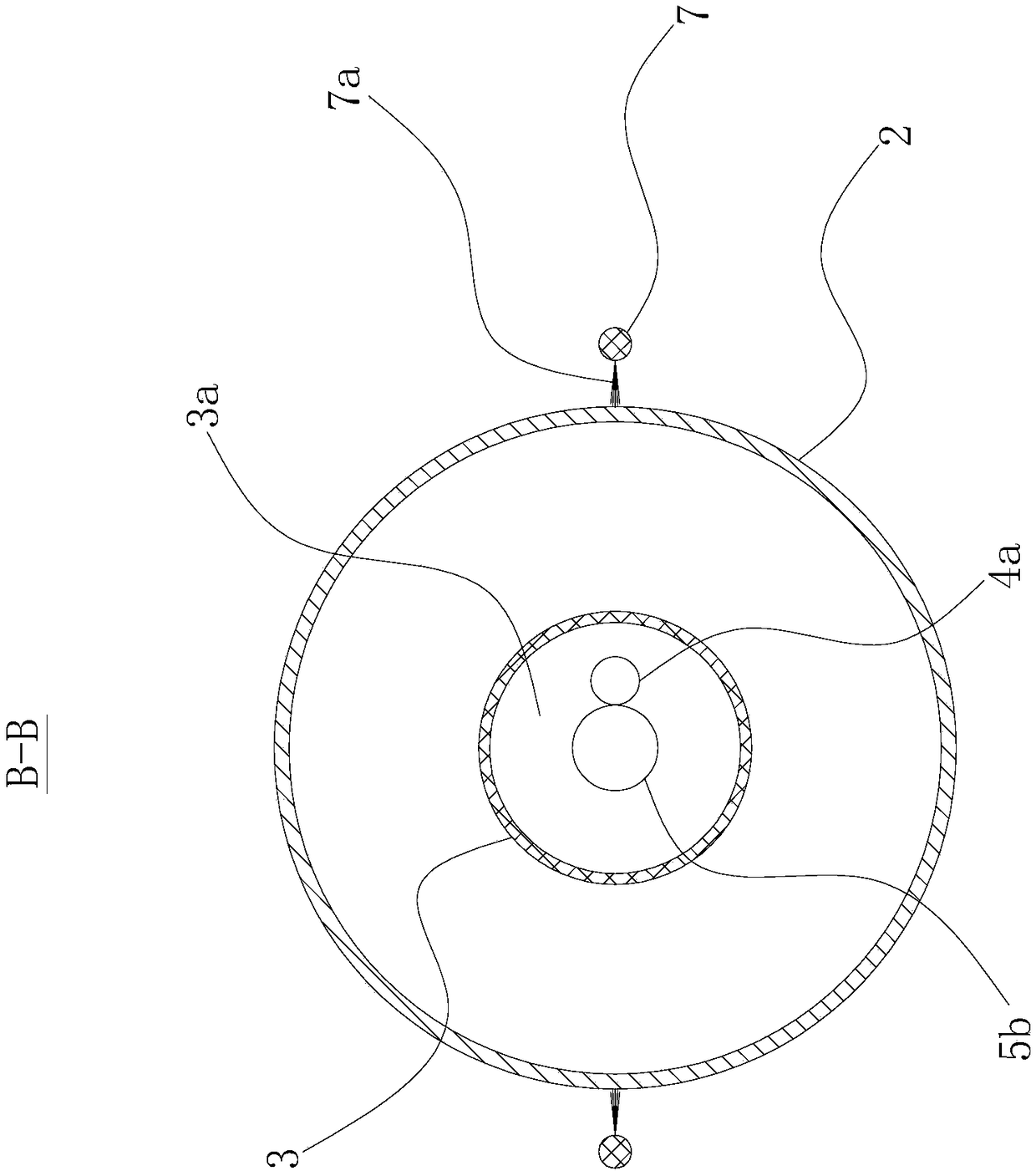

[0032] refer to Figures 1 to 4 , a net cage with automatic cleaning and feeding functions, comprising an annular floating body 1 and a cylindrical net cage 2, the upper end of the net cage 2 is provided with an opening 2a, and the floating body 1 is fixed on the net cage On the opening 2a of 2, the net cage 2 is coaxially arranged with the floating body 1, the bottom of the net cage 2 is provided with an equipment box 3, and the equipment chamber 3a is provided in the equipment box 3, and the rotation in the equipment chamber 3a Be provided with drive shaft 5, the lower end of described drive shaft 5 passes equipment chamber 3a and extends to the outside of net cage 2 and end is provided with impeller 5a, and the end that described drive shaft 5 stretches out net cage 2 is provided with and can clean net. A cleaning mechanism for algae and marine organisms on the bottom of the box 2 and on the surrounding wall, a motor one 4 is also provided in the equipment chamber 3a, and t...

Embodiment 2

[0047] The second embodiment is basically the same as the first embodiment, the difference is that, as Figure 4 As shown, the outer side of the floating ball 10 is provided with a permanent magnet layer 10b. When two adjacent floating balls 10 approach each other under the action of waves, since the magnetic poles of the two floating balls 10 are the same, a repulsive force will be generated. Make the two floats 10 away from each other, prevent the connecting rope 1f connecting the two floats 10 from being entangled with each other, and affect the power generation efficiency of the power generation mechanism in the float 10; in addition, the repulsive force generated between the two floats 10 also The number of rotations of the floating ball 10 can be increased to increase the power generation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com