Actuating unit for a process valve and process valve

A process valve, a separate technology, applied in the direction of engine components, fluid pressure actuation devices, fluid pressure actuation system safety, etc., can solve problems such as high expenditure of actuation units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

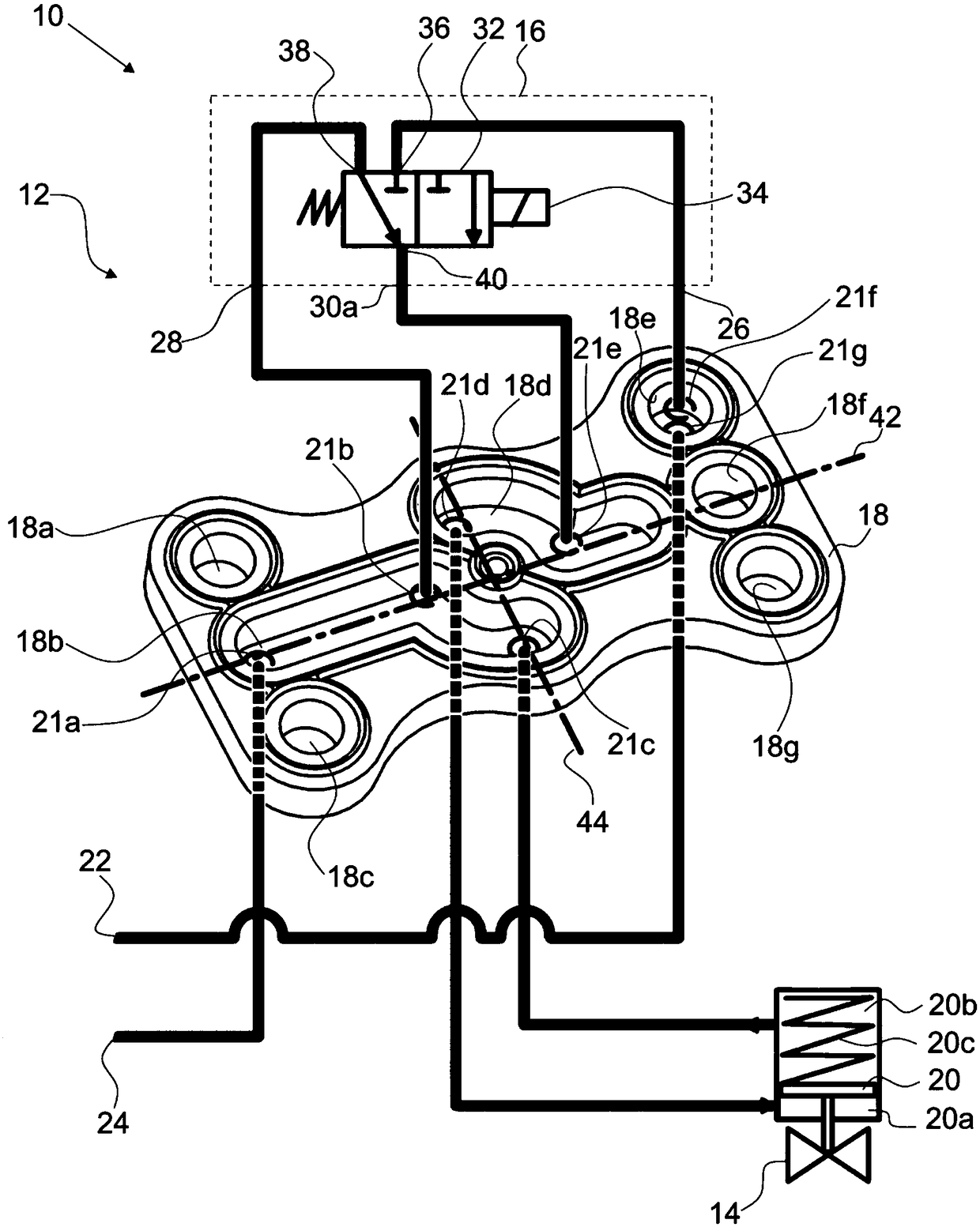

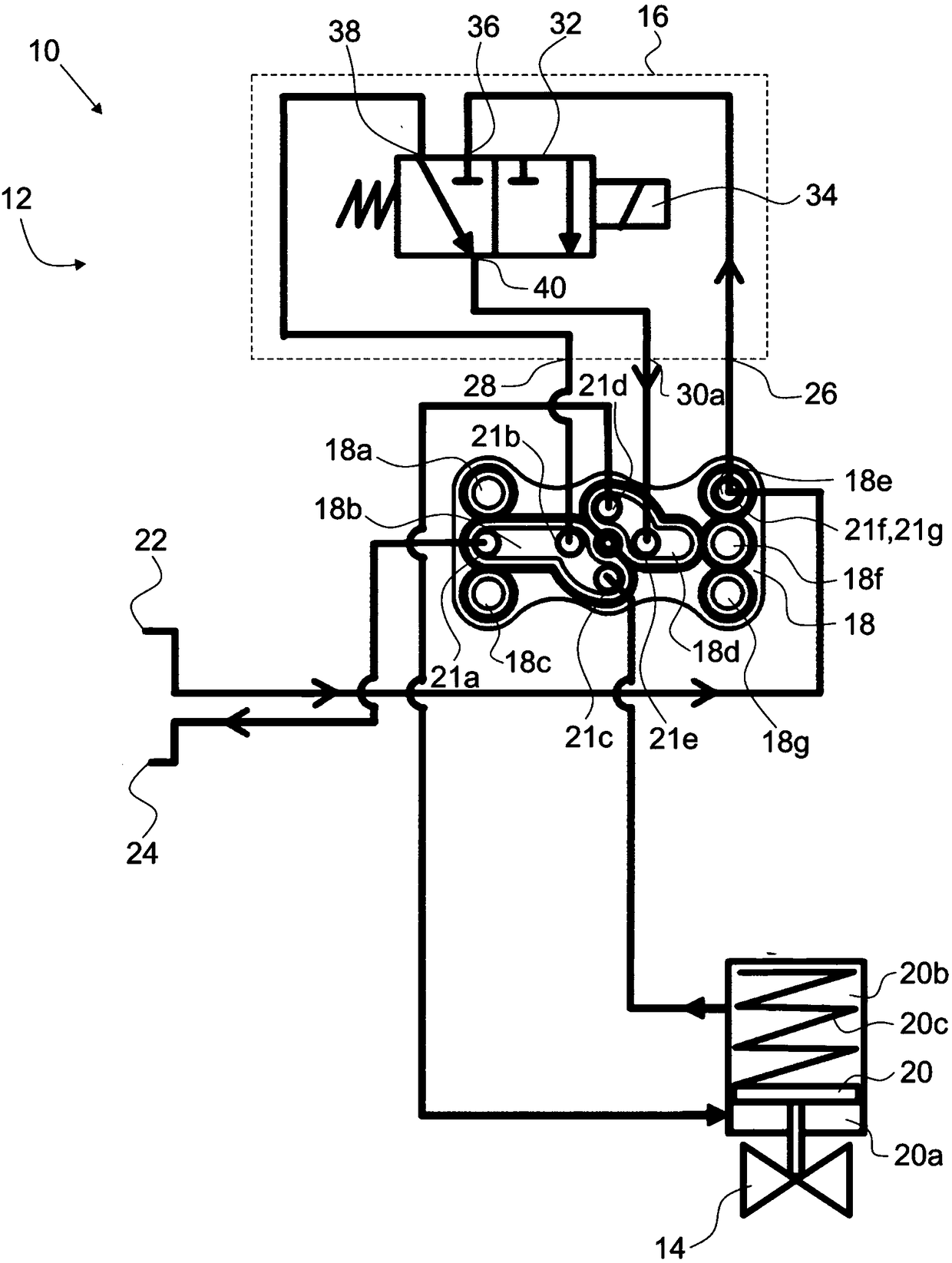

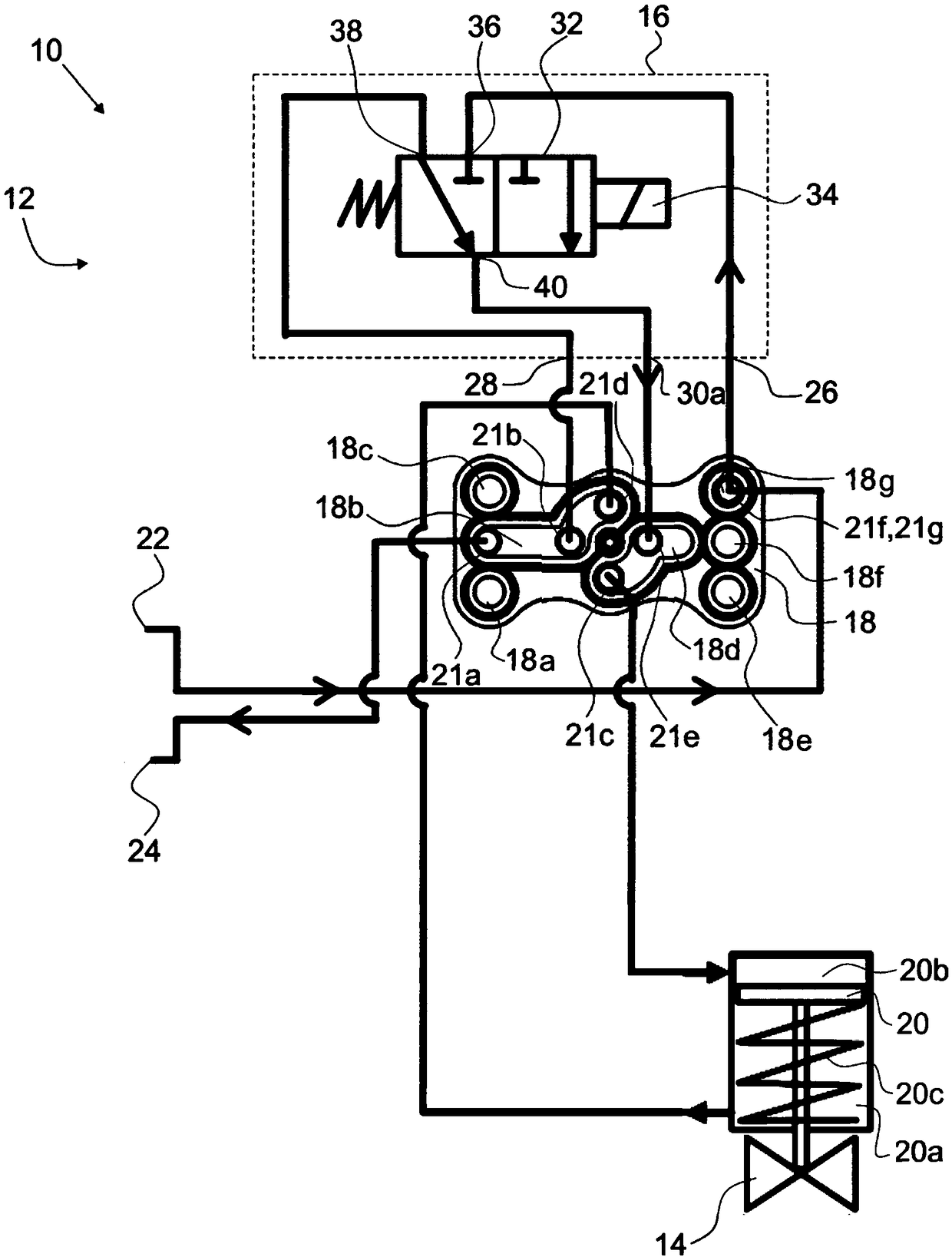

[0067] figure 1 with figure 2 A process valve 10 is shown which comprises an actuation unit 12 according to the first embodiment and a valve unit 14 which is indicated only symbolically. The actuation unit 12 may also be referred to as a pilot unit of the valve unit 14 .

[0068] The actuating unit 12 comprises a pilot valve unit 16, a separate removable seal 18 and a piston 20 configured for regulating the process valve 10, more precisely the valve unit 14, and is connected to the first pressure chamber 20a adjoins the second pressure chamber 20b.

[0069] The two pressure chambers 20a, 20b are arranged on opposite sides of the piston 20 and are preferably arranged in a cylinder, not referred to in detail, in which the piston 20 is also guided.

[0070] Furthermore, an elastic element 20c is arranged in the second pressure chamber 20b and is a spring in the illustrated embodiment. The elastic element 20c pushes the piston 20 in the direction of an end position correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com