Jet vortex spinning twister and operation method thereof

An operation method and twister technology, which is applied in the field of air-jet vortex spinning twisters, can solve problems such as easy air leakage, easy air leakage into dust, and reduced twisting force, so as to achieve less air leakage, improved twisting effect, The effect of increasing twist strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

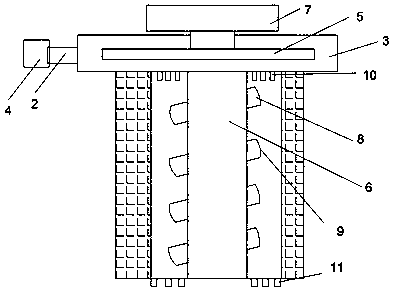

[0023] Such as figure 1 As shown, an air-jet vortex spinning twister provided in this embodiment includes a twister body 1, and an air circuit circulation chamber 3 with an air inlet pipe 2 on the side is arranged above the twister body 1. A heater 4 for heating the gas is connected to the top, a motor 7 is arranged above the air circulation chamber 3, and an output shaft of the motor 7 extends into the air circulation chamber 3 to be provided with a circulation fan 5. The twister body 1 is provided with a fixed column 6, and an air path guide rod 8 is spirally arranged on the fixed column 6. The end of the air path guide rod 8 is an inclined arc curve 9, and the air path The two sides of the connection between the circulation chamber 3 and the twister body 1 are respectively provided with more than one air inlet small hole 10 passing through the air circuit circulation chamber 3, and the two sides of the fixed column 6 are arranged below the twister. More than one small air ...

Embodiment 2

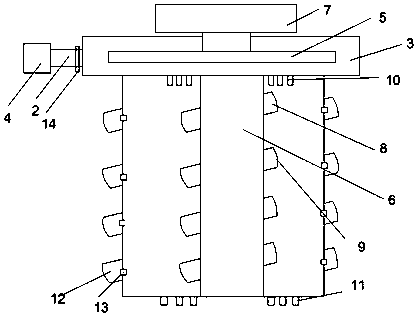

[0025] Such as figure 2 As shown, in the air-jet vortex spinning twister provided in this embodiment, further, on the outside of the twister body 1, an extension part 12 arranged helically on the periphery of the twister is provided, and the extension part 12 It communicates with the inside of the twister body 1 through a pipeline 13 .

[0026] Further, in order to improve the filtration efficiency and prevent blocking the air path, a filter screen 14 is inserted into the air inlet pipe 2. Through the above structural design, the extension part 12 is added to guide the direction of the wire, and at the same time, the filter screen 14 reduces the Gas impurities, to avoid the internal speed affecting the twisting effect.

Embodiment 3

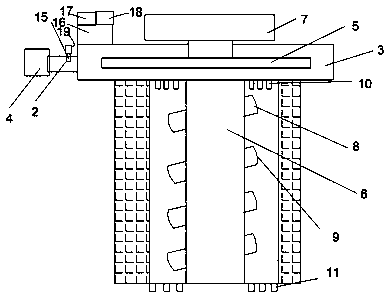

[0028] Such as image 3 As shown, in the air-jet vortex spinning twister provided in this embodiment, further, an air circuit monitor 15 is plugged into the air inlet pipe 2, and a controller 16 is electrically connected to the air circuit monitor 15 .

[0029] Further, a display 17 is connected to the controller 16 .

[0030] Further, a bluetooth device 18 is connected to the controller 16 .

[0031] Further, an air hole regulator 19 is connected to the gas path monitor 15. Through the above-mentioned structural design, the size of the gas path can be automatically controlled, and the monitoring and display of the gas path dynamics can be implemented, and the Bluetooth device 18 can be used to realize data transmission via Bluetooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com