Apple screening device using centrifugal force for controlling screening

A screening device and centrifugal force technology, applied in the field of fruit processing, can solve the problem that the size of the screening hole is fixed and cannot be changed, and achieve the effect of facilitating the screening work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

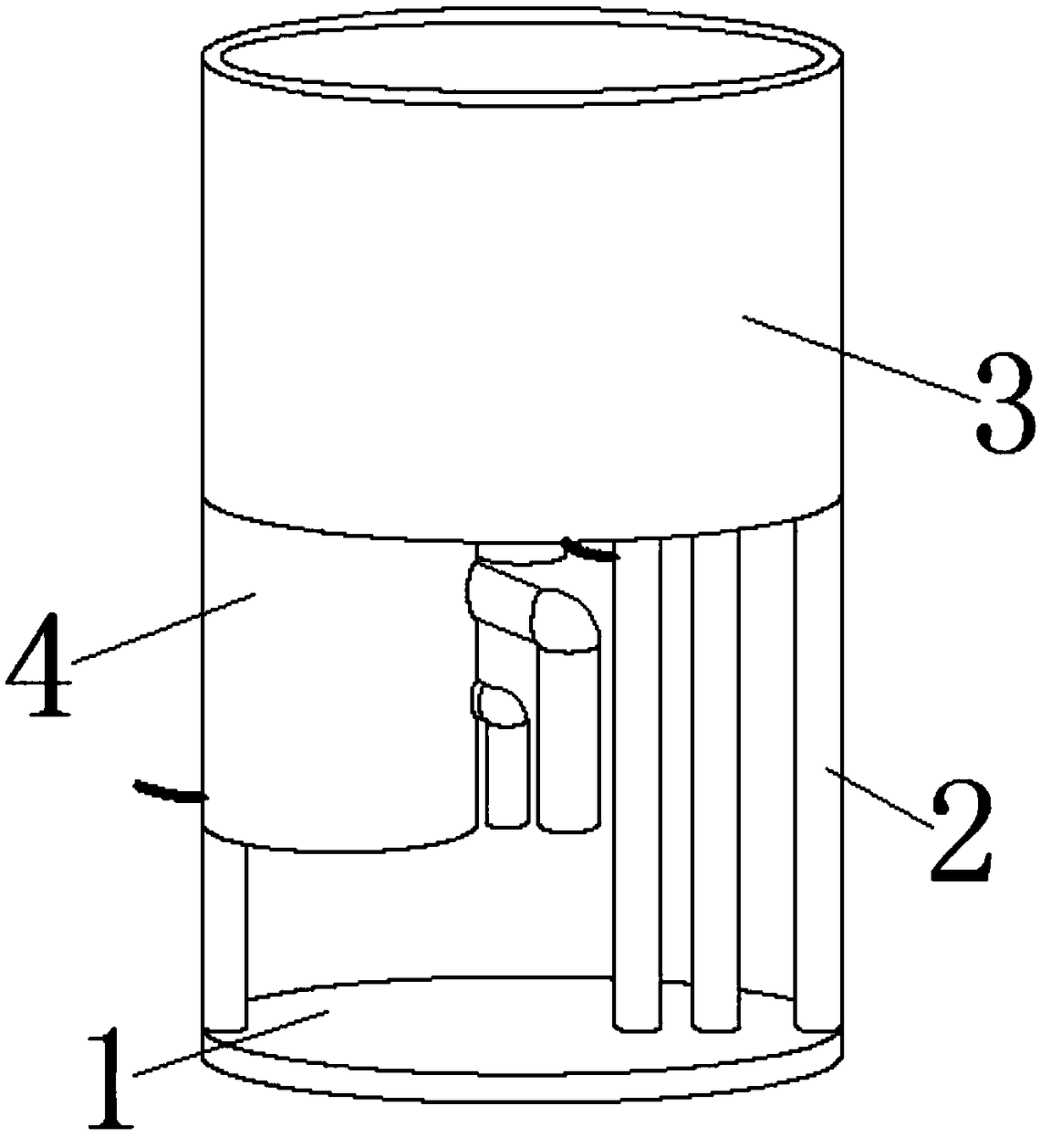

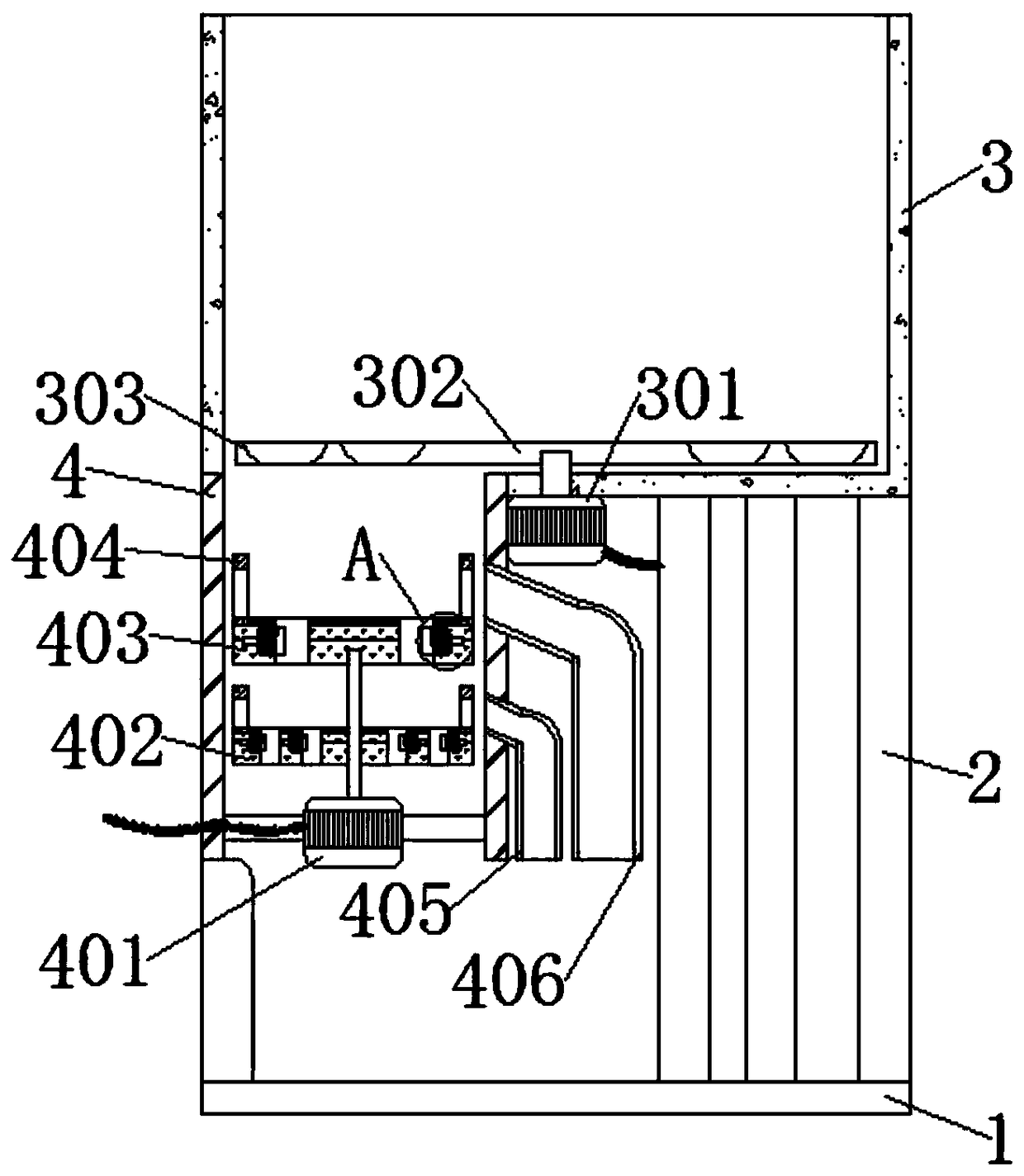

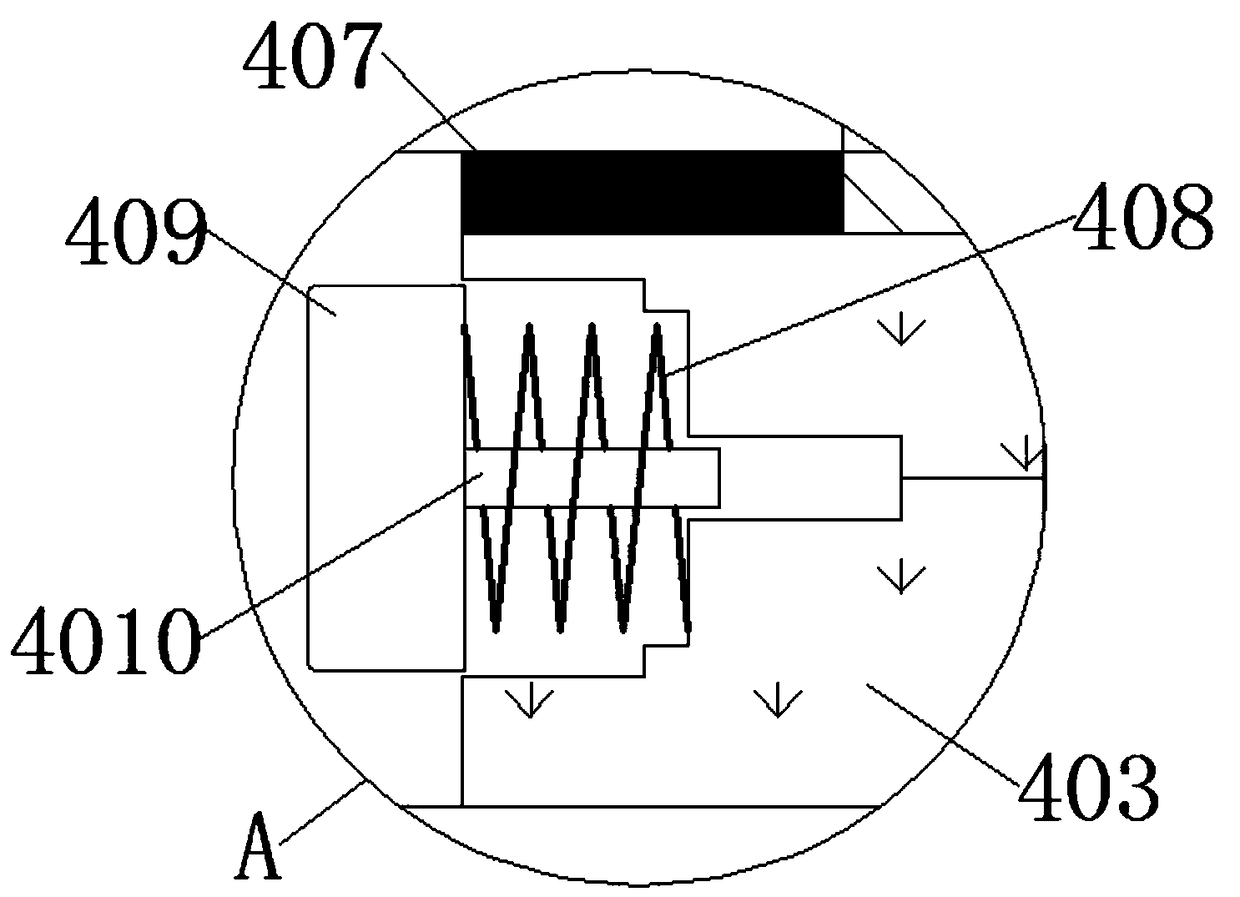

[0025] see Figures 1 to 7 Among them, in the embodiment of the present invention, an apple screening device that uses centrifugal force to control screening includes a bottom plate 1, a storage tank 3, a screening cylinder 4 and a bracket 2. The top of the bottom plate 1 is welded with four brackets 2, and the top of the bracket 2 The top is respectively welded with a screening cylinder 4 and a storage tank 3, and one side of the bottom of the screening cylinder 4 is embedded and welded with a screening cylinder 4; Welding is provided with damping motor 301, and the top welding of damping motor 301 is provided with disc 30202, and the inner opening of disc 30202 is provided with circular hole 303; Screening drum 4 comprises motor 401, second screening plate 402, first screening plate 403, Ring plate 404, small tube body 405, large tube body 406, rubber sheet 407, spring 408, block 409 and positioning bolt 4010, the inner wall of the screening cylinder 4 is welded with a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com