Automatic tea leaf deblocking machine

A deblocking machine and deblocking technology, which is applied in the field of automatic tea deblocking machines, can solve the problems of unsatisfactory deblocking effect, low deblocking efficiency, and time-consuming deblocking, so as to reduce labor costs and improve deblocking efficiency High, less damage to tea leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

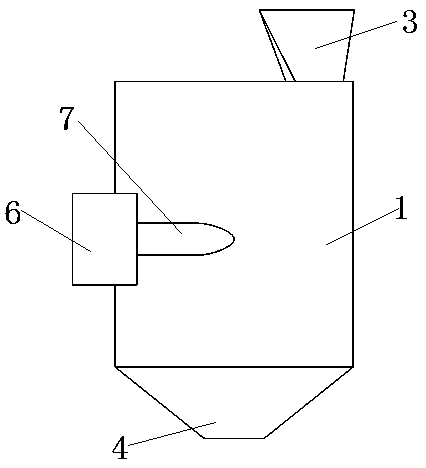

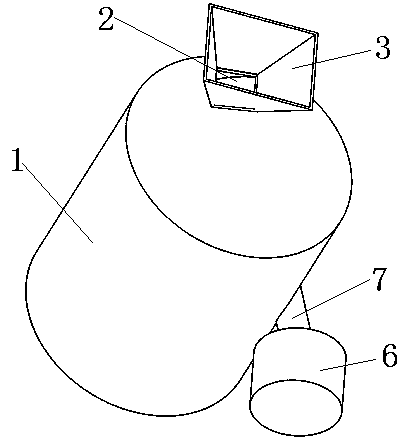

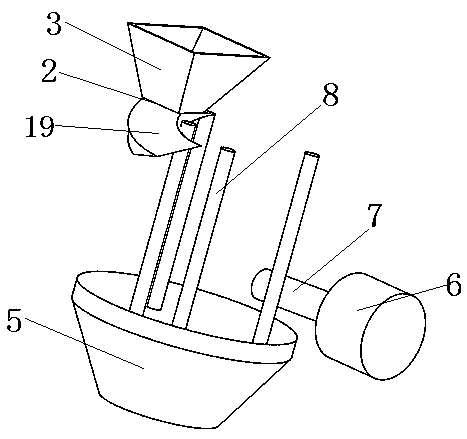

[0034] Such as Figure 1~4 As shown, an automatic tea deblocking machine includes a deblocking cylinder 1 and a fan 6, the top of the deblocking cylinder 1 is provided with a feed port 2, and the upper end of the feed port 2 is connected with a feed funnel 3, the The bottom end of the deblocking cylinder 1 is provided with a discharge port 4, and a filter screen 5 is installed in the deblocking cylinder 1, and the side wall of the deblocking cylinder 1 is provided with an air inlet 7 communicating with the fan 6, and the air inlet 7 is connected to the air outlet of the fan 6 through an air duct, and a plurality of deblocking rods 8 are fixedly installed in the deblocking cylinder 1 .

[0035] The principle of this embodiment is to use the fan 6 to provide high-speed wind into the deblocking cylinder 1 through the air inlet 7, so as to drive the tea leaves to rotate at high speed in the deblocking cylinder 1, and the rotating tea balls collide with the fixed deblocking rod 8 f...

Embodiment 2

[0042] This embodiment is based on Embodiment 1, the difference is:

[0043] In this example, if Figure 5 As shown, the air inlet 7 is also installed with a swing assembly, including a swing air duct 11 and a connecting air duct (not shown in the figure), and the swing air duct 11 includes an air outlet located in the deblocking cylinder 12 and the rotating part 13 installed in the wall of the deblocking cylinder 1 along the radial direction of the deblocking cylinder 1, the rotating part 13 is connected with the connecting air pipe, and the connecting air pipe is a flexible PE pipe, flexible Good performance, connected with the fan 6, the rotating part 13 of the swing air duct 11 is fixedly sleeved with a connecting rod 14, and the other end of the connecting rod 14 is rotatably connected with a swing rod 15, and the swing rod 15 is in addition One end is rotatably installed at the eccentric position of the swing wheel 16, and the swing wheel 16 is driven by a drive motor 1...

Embodiment 3

[0047] This embodiment is based on Embodiment 1, the difference is:

[0048] Such as Figure 8 As shown, the deblocking rods 8 are arranged in a staggered manner in the deblocking cylinder 1 to increase the probability of collision between the tea balls and the deblocking rods 8 and improve the deblocking efficiency.

[0049] Such as Figure 9 As shown, the surface of the deblocking rod 8 is provided with arc-shaped protrusions 18 to increase the efficiency of deblocking, and at the same time prevent the tea leaves from directly hitting the deblocking rod 8 to reduce tea damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com