Vehicle rack-and-pinion mechanism

A technology of rack and pinion and gear teeth, which is applied in the field of rack and pinion mechanisms for vehicles, can solve problems such as deformation of the steering rack shaft, and achieve the effect of improving strength and suppressing weight increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] One embodiment of the present invention will be described in detail with reference to appropriate drawings. The same reference numerals are assigned to the same constituent elements, and overlapping descriptions are omitted.

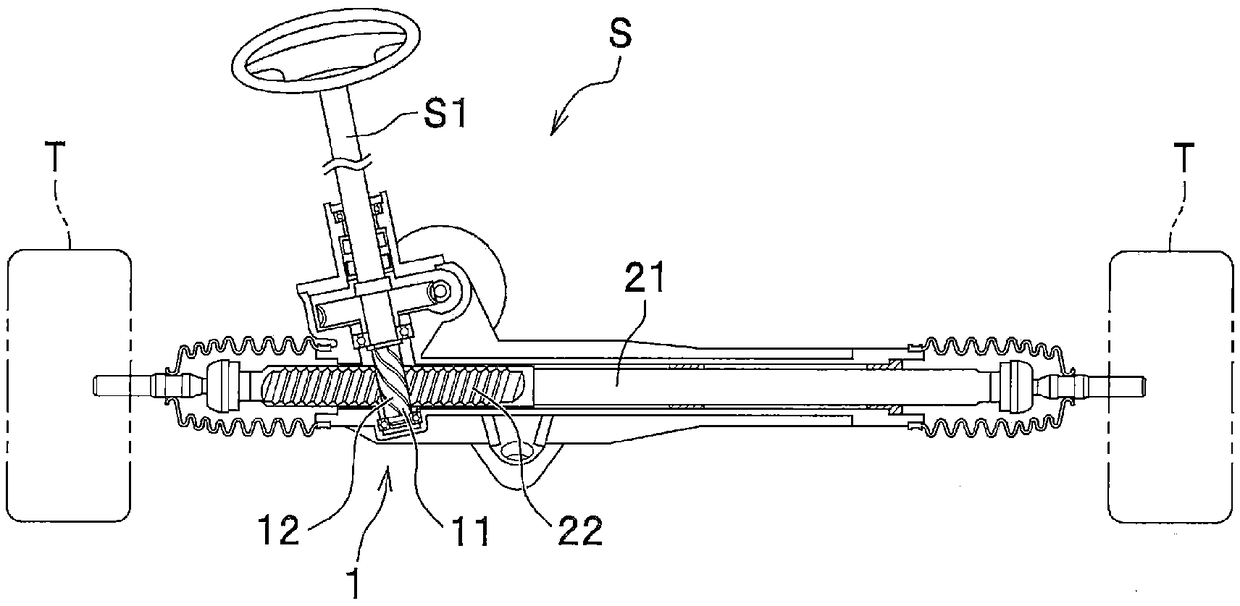

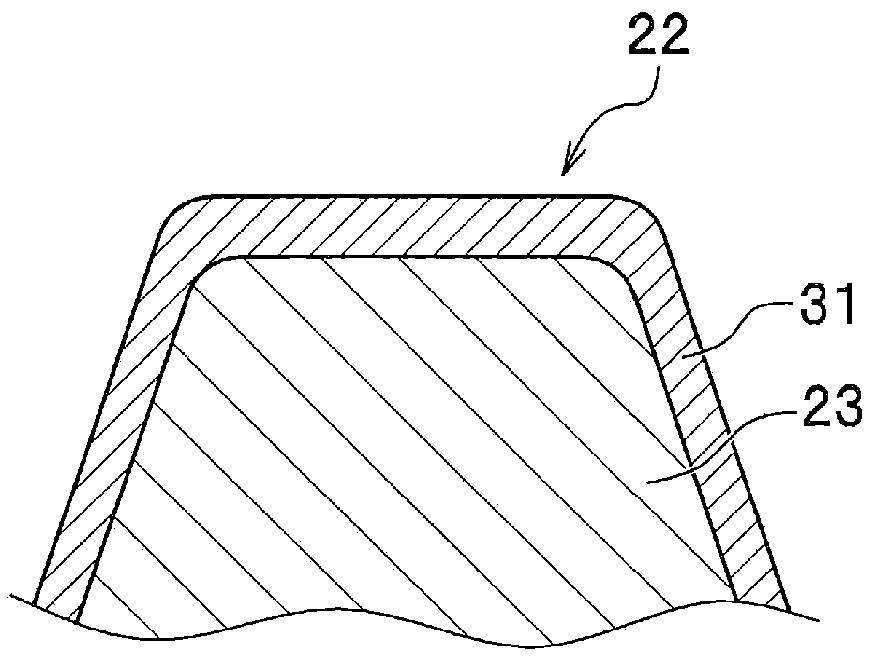

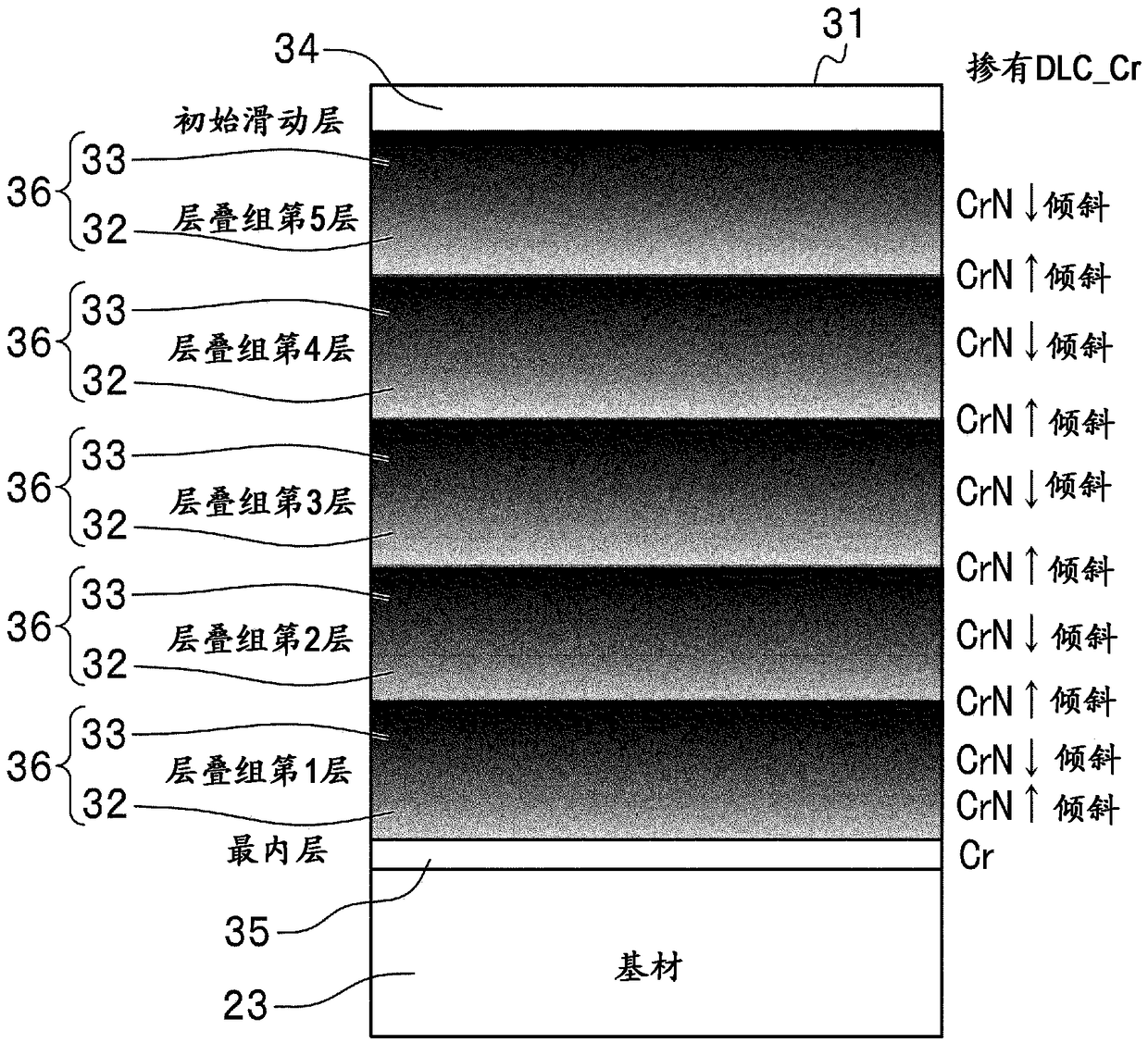

[0029] Such as figure 1 As shown, the rack-and-pinion mechanism 1 for a vehicle according to this embodiment includes a pinion gear 11 provided with pinion teeth 12 and rotatably supported around an axis, and a pinion gear 11 provided with rack teeth 22 capable of meshing with the pinion teeth 12 . Bar axis 21. In addition, the rack-and-pinion mechanism 1 for a vehicle according to this embodiment constitutes a steering device S for a vehicle.

[0030] That is, the pinion gear 11 constitutes a steering shaft S1, and rotates about its axis in conjunction with a steering operation. Then, when the pinion gear 11 rotates, the engaged rack teeth 22 slide to change the steering angle of the tire T. As shown in FIG.

[0031] In such a steering device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com