Pneumatic tire

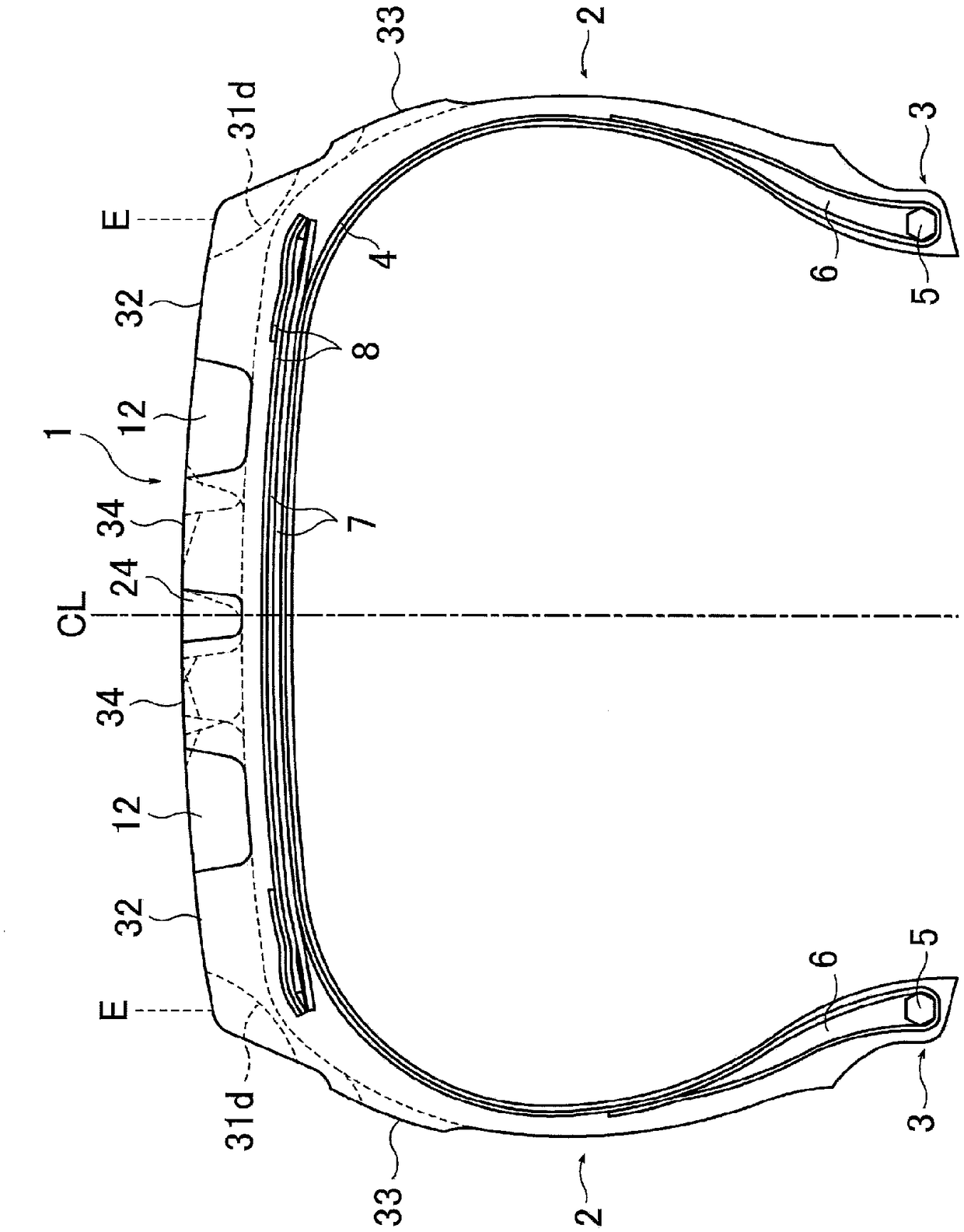

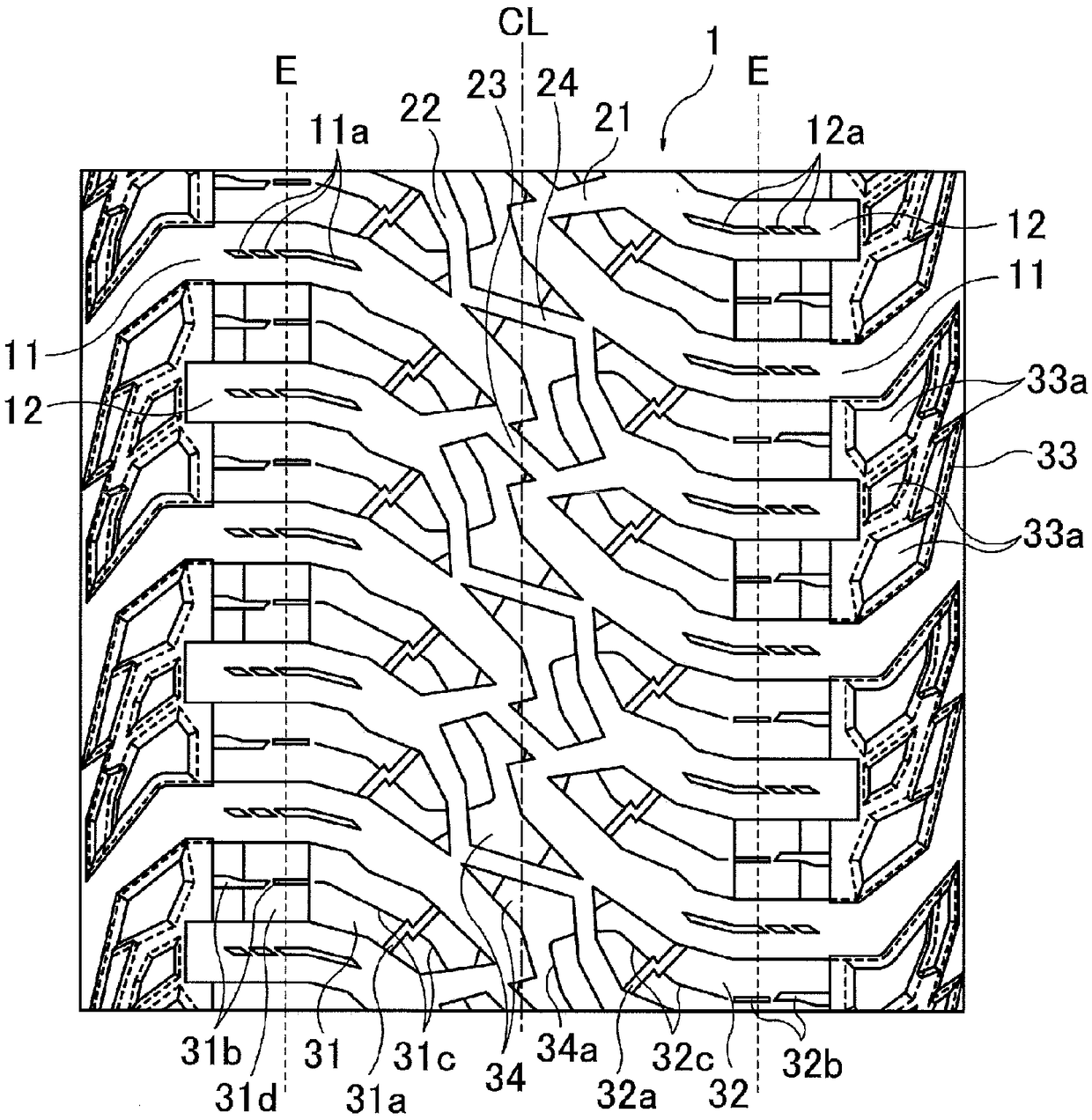

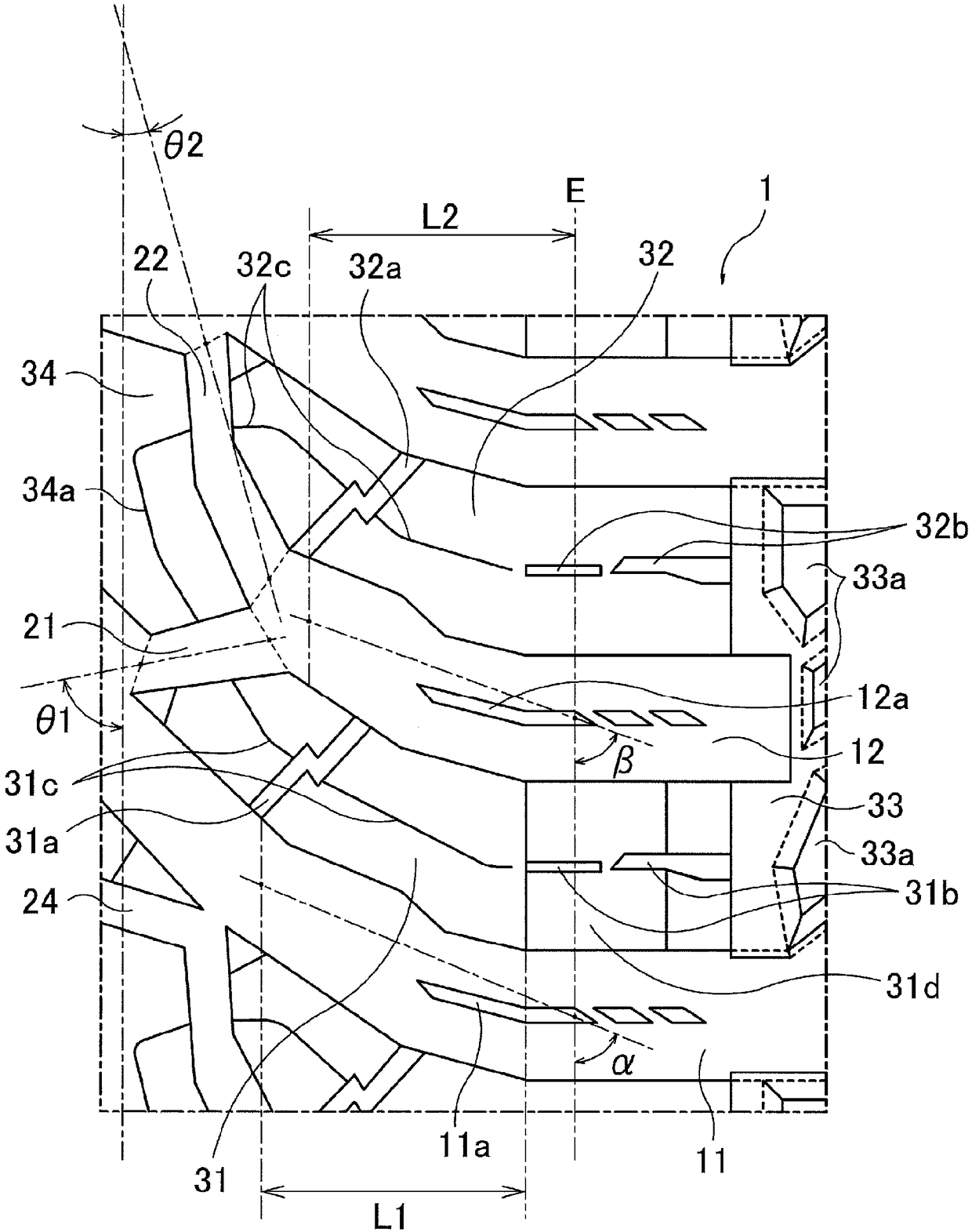

A technology of pneumatic tires and tires, which is applied in the direction of off-road vehicle tires, tire parts, tire treads/tread patterns, etc., which can solve the problems of reduced partial wear resistance, reduced rigidity, and prone to partial wear, so as to improve the wear resistance Unbiased wear resistance, improved mud performance, roughly equal rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] The tire size is LT265 / 70R17, with figure 1 The illustrated basic structure, with figure 2 Based on the tread pattern, set the relationship between the magnitude of the angle of the first connecting groove and the second connecting groove (the angle of the first / second connecting groove), the position of the cross-cutting groove, the position of the first cross-cutting groove, and the Angle α with respect to the tire circumferential direction at the position of the ground contact end of the groove, angle β with respect to the tire circumferential direction at the position of the ground contact end of the second lateral groove, presence or absence of the third connecting groove and the fourth connecting groove (third / the presence or absence of the fourth connecting groove), the magnitude relationship between the angle θ3 of the third connecting groove relative to the tire circumferential direction and the angle θ4 of the fourth connecting groove relative to the tire ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com