Ventilation and heat dissipation structure of high voltage switch cabinets

A high-voltage switchgear, ventilation and heat dissipation technology, applied in the cooling/ventilation of substation/switchgear, details of substation/switch layout, electrical components, etc., can solve the problems of circuit components, no ventilation and heat dissipation structure, and influence on line power. Achieve the effect of preventing rainwater from entering and excellent heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

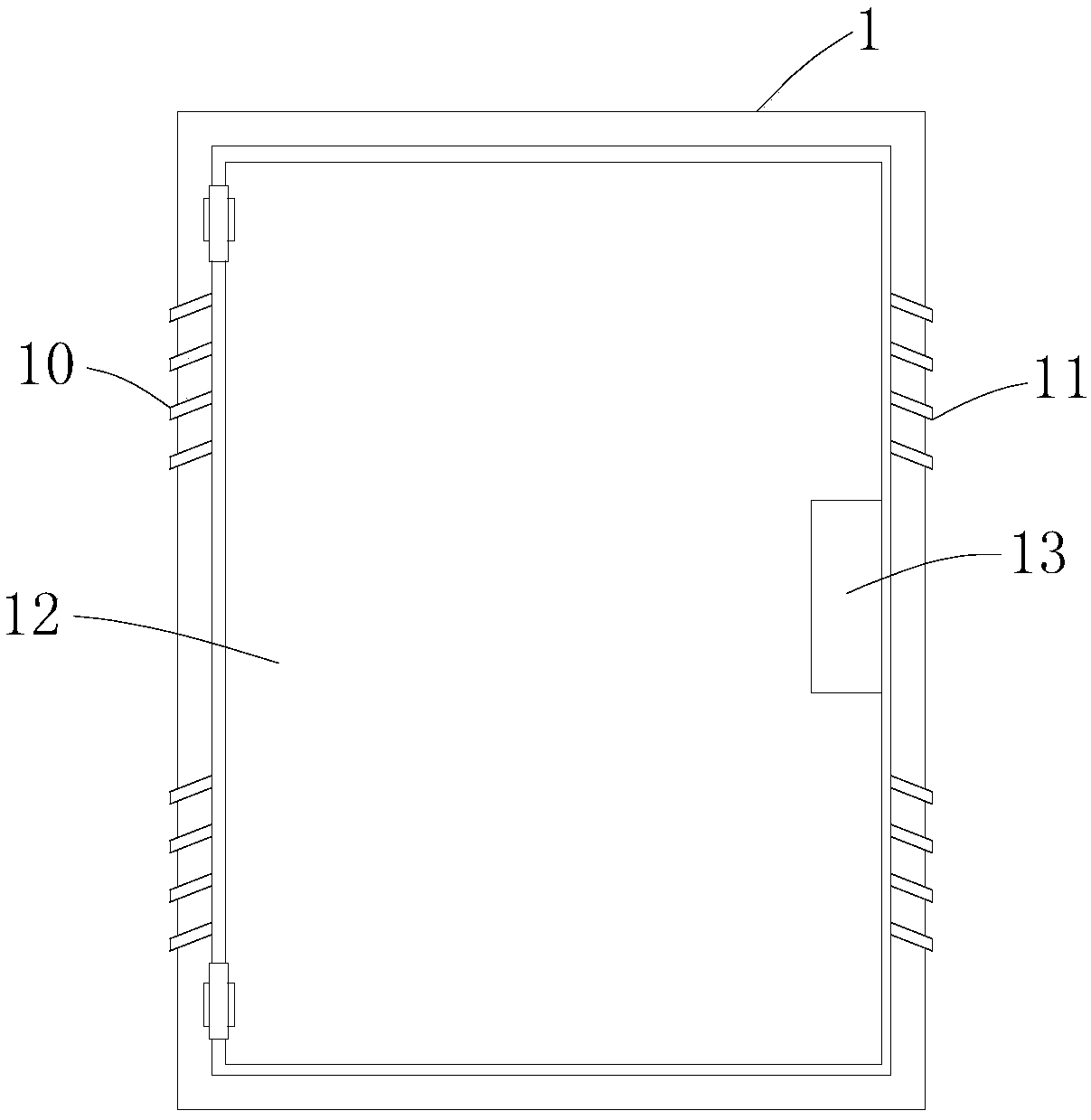

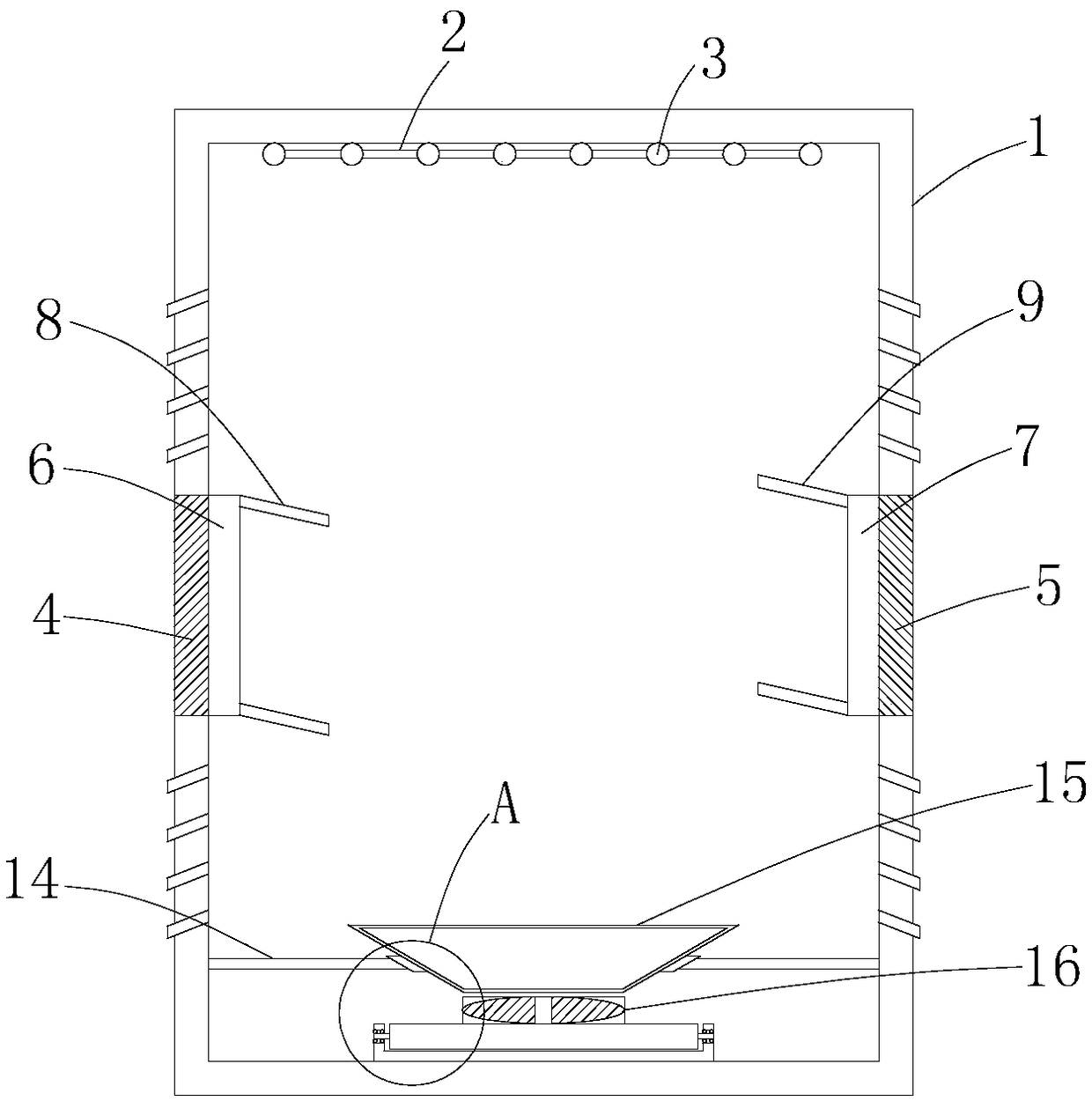

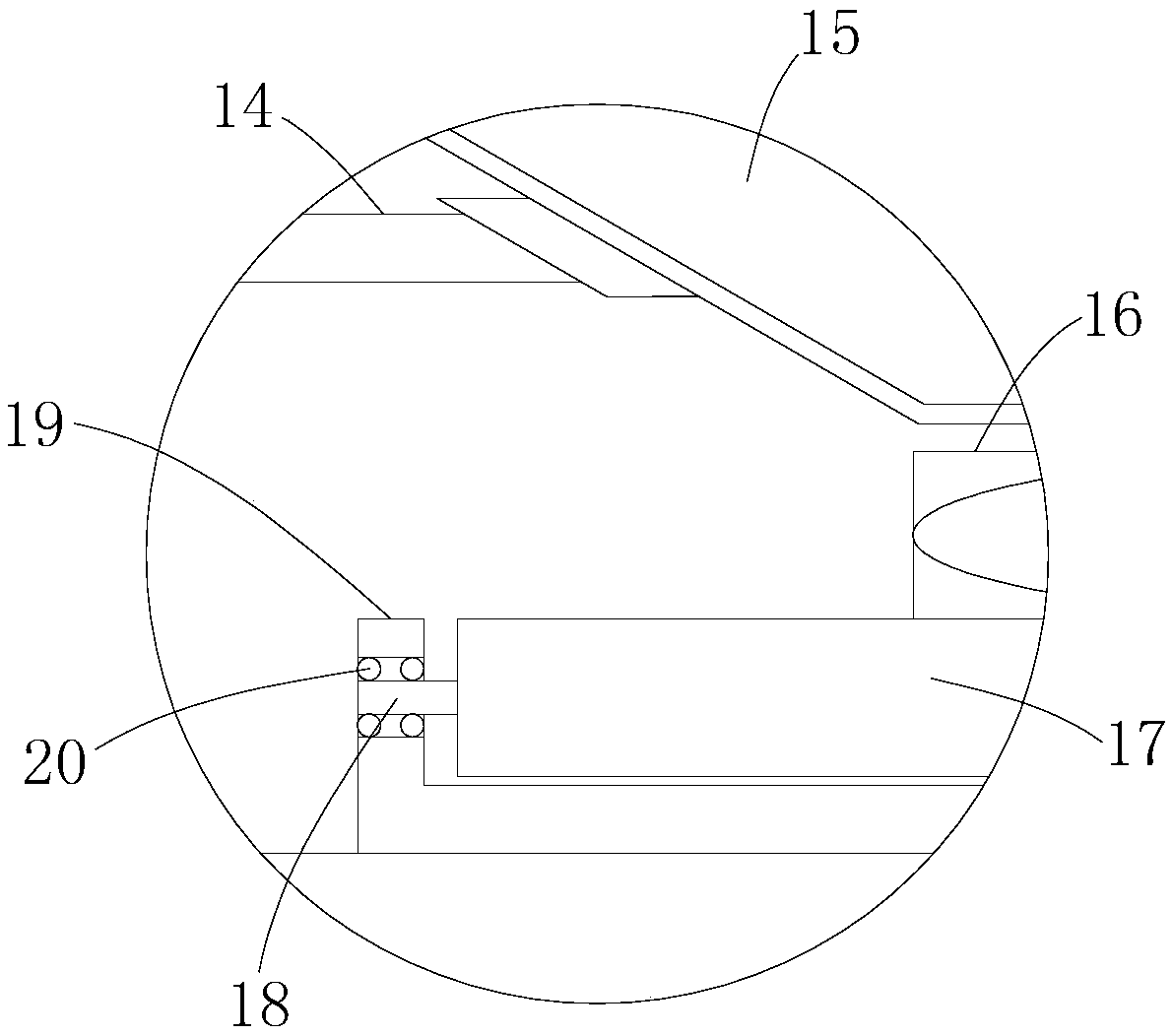

[0022] like Figure 1-4 As shown, the present invention provides a technical solution: a ventilation and heat dissipation structure of a high-voltage switchgear, including a switchgear body 1, a left rubber pad 4, a right rubber pad 5, an air induction bucket 15, an exhaust fan 16, and a left rubber pad 4 It is located at the left middle position of the inner wall of the switch cabinet body 1, the right rubber pad 5 is located at the right middle position of the inner wall of the switch cabinet body 1, the air induction bucket 15 is located at the bottom of the inner cavity of the switch cabinet body 1, and the exhaust fan 16 is located at the air induction bucket 15 The bottom of the switchgear body 1 is provided with a through groove in the middle of the left and right sides, the left rubber pad 4 is arranged in the through groove on the left side of the switchgear body 1, and the left rubber pad 4 is arranged in the through groove on the right side of the switchgear body 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com