A method for simulating the formation of emulsion spots on cold rolled strip

A cold-rolled strip and emulsion technology, applied in the field of steel cold-rolling, can solve problems such as affecting the production efficiency and economic benefits of enterprises, reducing the product qualification rate, affecting the quality of strip steel, etc., achieving strong operability and repeatability, improving Surface quality, the effect of eliminating emulsion stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] For the situation of Comparative Example 1, the formation process of the cold-rolled strip emulsion spot is simulated by the simulation method described in the present invention, so that the cold-rolled liquid can be selected and adjusted without affecting production, so as to reduce or even eliminate the cold-rolled strip surface The generation of emulsion spots improves the surface quality of cold-rolled strip products.

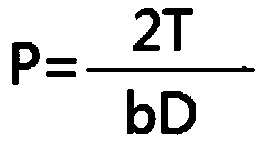

[0069] There is a huge pressure when the cold-rolled strip is rolled and crimped, which can reach 0.19 MPa according to calculations, and the surface temperature of the cold-rolled strip is relatively high, the highest temperature can reach 150°C, and the emulsion drips from the rolling outlet, so after crimping The surface of cold-rolled strip steel is in an environment of high pressure, high temperature, lack of oxygen, and water vapor.

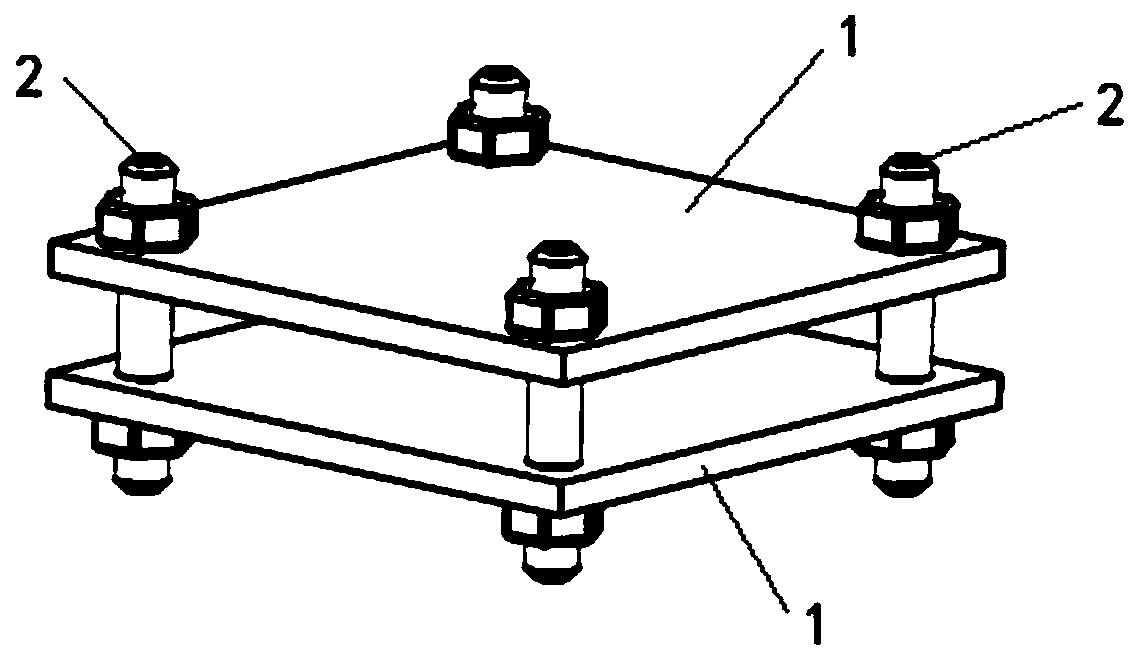

[0070] The present invention is as follows to the simulation process of above-mentioned working condition:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com