Intelligent inspection device of petrochemical enterprise

An intelligent inspection and enterprise technology, applied in the direction of instruments, computer control, simulators, etc., can solve the problem of not being able to notify the on-site inspection personnel at the first time, the work experience of the inspection personnel is greatly affected, and the workload of the inspection personnel cannot be quantified and other problems, to achieve the effect of authenticity and reliability of detection data, improvement of inspection efficiency, and realization of spatial three-dimensional positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

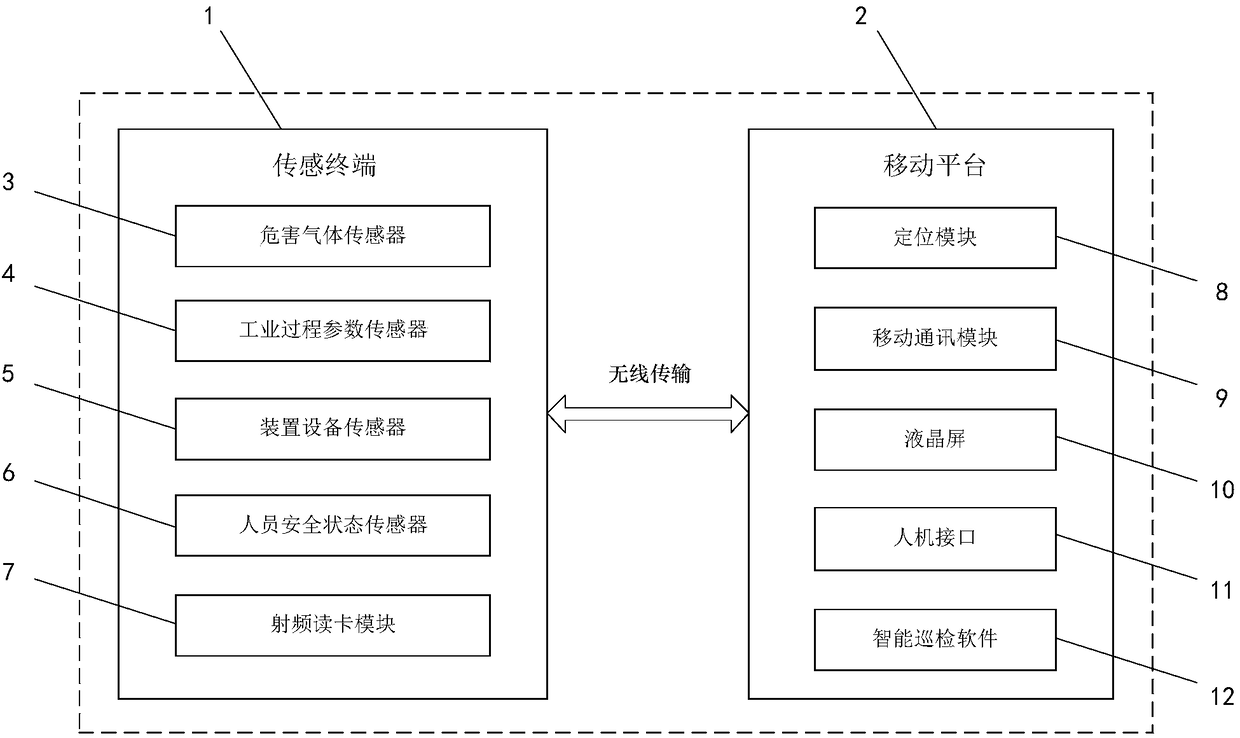

[0027] Combine figure 1 As shown, an intelligent inspection device for petrochemical enterprises includes a sensor terminal 1, a radio frequency positioning card, and a mobile platform 2. Among them, the sensor terminal 1 and the mobile platform 2 transmit data wirelessly.

[0028] The sensor terminal 1 includes a hazardous gas sensor 3, an industrial process parameter sensor 4, a device equipment sensor 5, a personnel safety status sensor 6 and a radio frequency card reader module 7.

[0029] Radio frequency positioning card, using active or passive mode, is fixedly installed at the inspection point of the device and the entrance and exit of the inspection route, and is used to locate the inspection point and the location of the inspector.

[0030] The mobile platform 2 includes a positioning module 8, a mobile communication module 9, an LCD screen 10, a human-machine interface 11, and so on.

[0031] The mobile platform 2 is used to accurately locate the location of inspectors, dis...

Embodiment 2

[0049] This embodiment 2 is different from embodiment 1 except for the following technical features, and other technical features can refer to the above embodiment 1.

[0050] A Bluetooth wireless transmission module is provided between the sensor terminal 1 and the mobile platform 2 in the second embodiment.

[0051] Data transmission is performed between the sensor terminal 1 and the mobile platform 2 through a Bluetooth wireless transmission module. The data transmission includes uploading the inspection data detected by the sensor terminal 1 on the one hand, and receiving the inspection guide data from the mobile platform 2 on the other hand.

Embodiment 3

[0053] Except for the following technical features of this embodiment 3 which are different from the foregoing embodiment 1 or 2, other technical features can refer to the foregoing embodiment 1 or 2.

[0054] The positioning module 8 in this embodiment 3 includes a GPS positioning module and a radio frequency positioning module.

[0055] First, use the radio frequency positioning module to locate the inspector's position in the device, and secondly use GPS for positioning.

[0056] The third embodiment effectively solves the problems of positioning failure and stereo positioning caused by the complicated on-site environment and weak GPS signal by using the positioning method that combines GPS and radio frequency card reading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com