Liquid additive putting device and putting method thereof

A technology of liquid additives and dispensing devices, which is applied to washing devices, household cleaning devices, washing machine control devices, etc., to achieve the effect of strong intelligence, simple structure, and ingenious principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

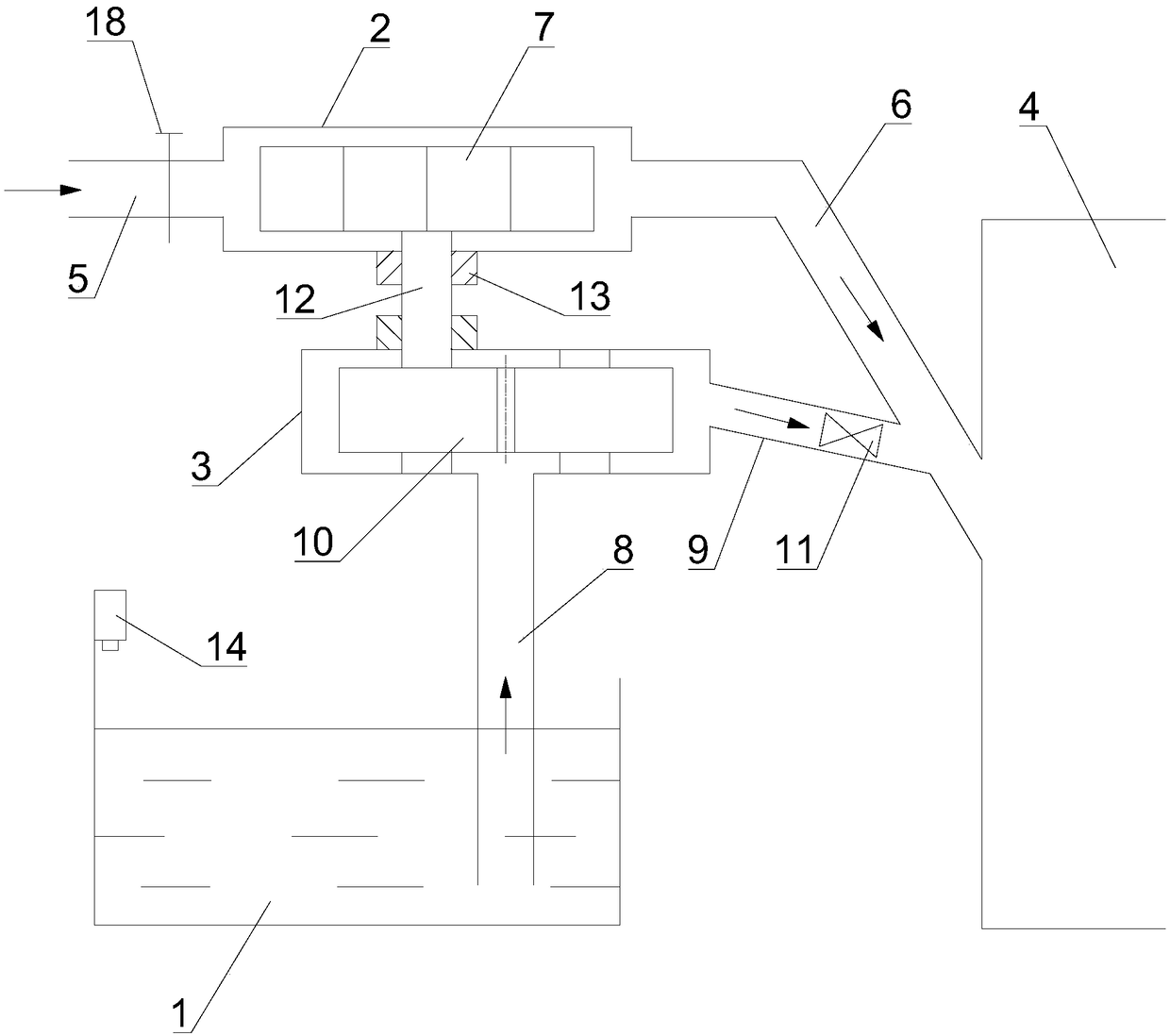

[0026] see figure 1 As shown, this embodiment provides a liquid additive dispensing device, taking a washing machine as an example of an application, including an additive storage box 1, a water supply chamber 2, an additive chamber 3 and a mixing cylinder 4 (here, the inner cylinder of the washing machine).

[0027] The water supply chamber 2 is provided with a water inlet 5 and a water inlet pipe 6 connected to the mixing cylinder 4. The water supply chamber 2 is provided with a blade wheel 7. When the water inlet 5 enters water, the water flow drives the blade wheel 7 to rotate. It should be noted that the water inlet 5 here is not the main water inlet of the washing machine, but only serves as a branch for absorbing additives, so there is no need to worry about the situation that washing with clean water cannot be performed.

[0028] The additive chamber 3 is provided with a suction pipe 8 and a branch pipe 9 connected to the water inlet pipe 6. The liquid suction pipe 8 e...

Embodiment 2

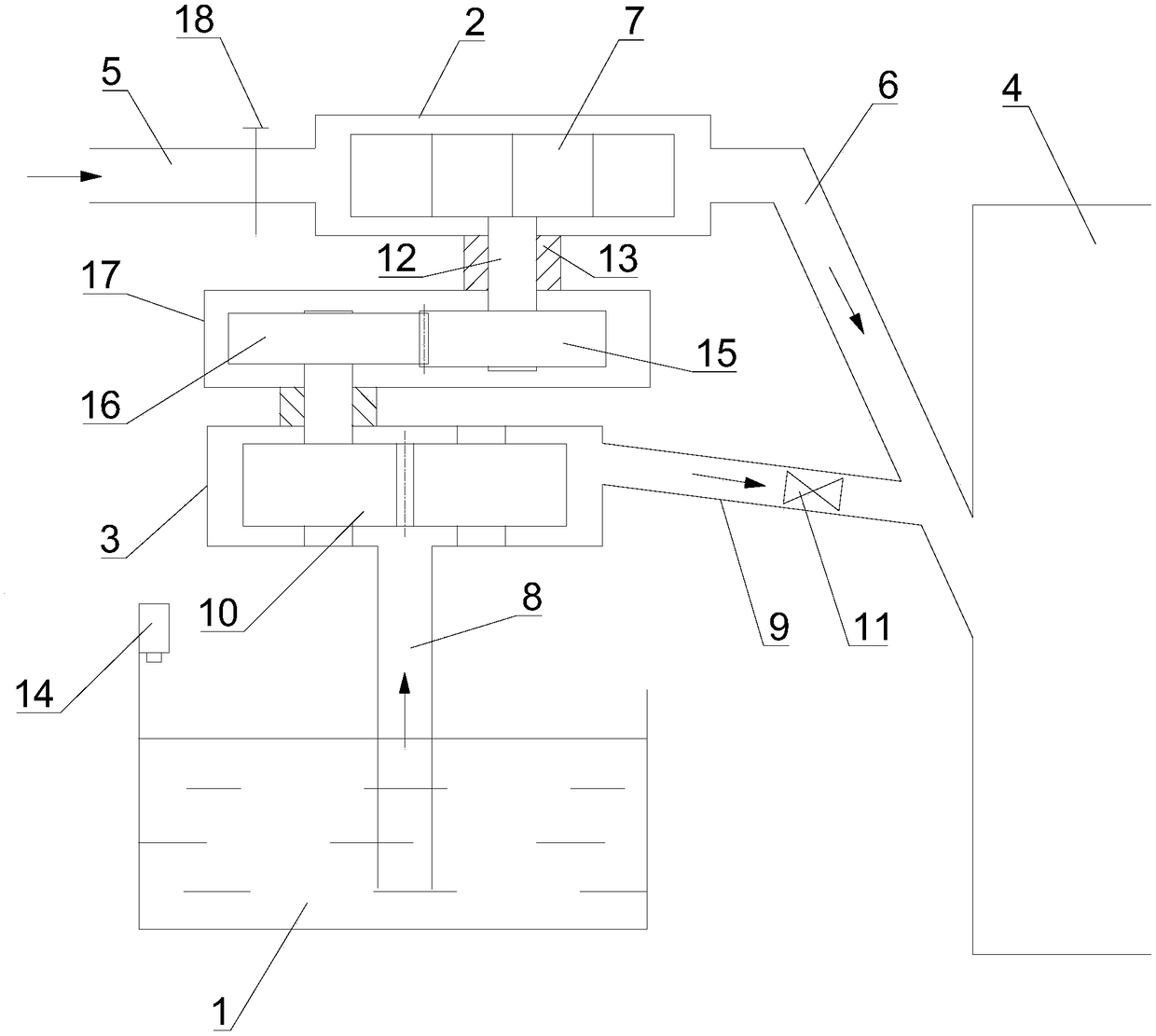

[0042] see figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the gear pump 10 is not directly fixed on the rotating shaft 12, but is indirectly driven by a transmission mechanism, such as a gear box, specifically, between the vane wheel 7 and the gear pump 10 A gearbox 17 is provided, and the gearbox 17 is provided with a first gear 15 and a second gear 16, the rotating shaft 12 is in transmission connection with the first gear 15, the drive shaft of the gear pump 10 is in transmission connection with the second gear 16, and the first gear 15 Engage with the second gear 16 for transmission. The advantage of such setting is that, according to the water inlet power, an appropriate transmission ratio is selected to adjust the suction of the additive chamber 3 .

Embodiment 3

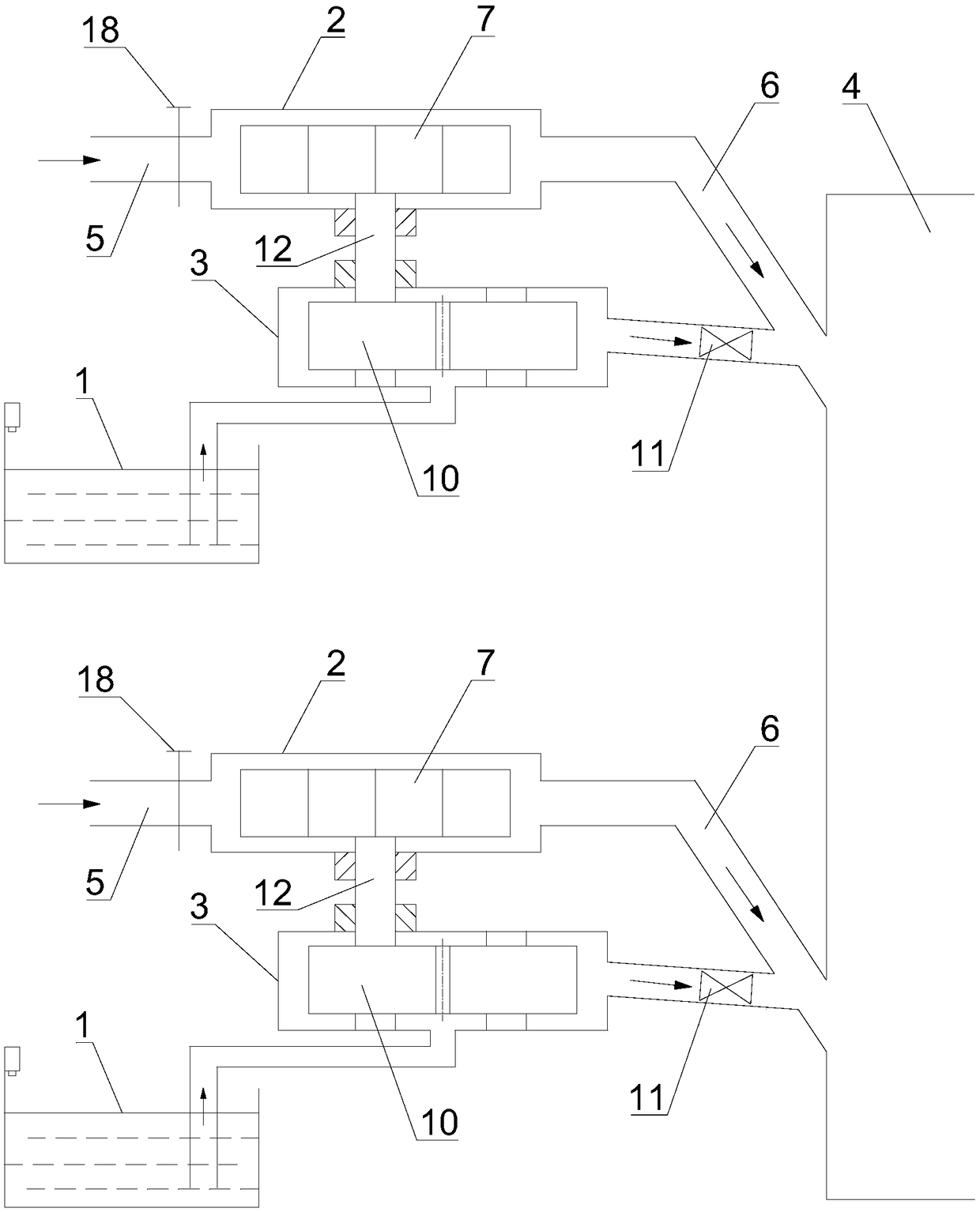

[0044] see image 3 As shown, on the basis of Embodiment 1, this embodiment is expanded into a plurality of additive storage boxes 1 , and each additive storage box 1 is correspondingly provided with a water supply chamber 2 and an additive chamber 3 . When washing clothes in a washing machine, more than one additive is often used, such as pre-washing liquid, main washing liquid, softener, conditioner, etc., and it needs to be used sequentially. At this time, it is not only cumbersome to add in batches, but also the dosage is difficult to control. Therefore, in this embodiment, two additive storage boxes 1 are used as an example, and multiple additives can be added simultaneously or sequentially, so as to reflect that the dispensing device has the function of dispensing diversified additives.

[0045]To sum up, the above-mentioned liquid additive dispensing device and its dispensing method are simple in structure and ingenious in principle. The impeller is driven by the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com