Vanadium-titanium-silicon molecular sieve, preparation method and application thereof, and sulfide oxidation method

A technology of titanium silicon molecular sieve and silicon molecular sieve, applied in the field of molecular sieve, can solve the problems of occupying land resources and inventory space, and achieve the effect of good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

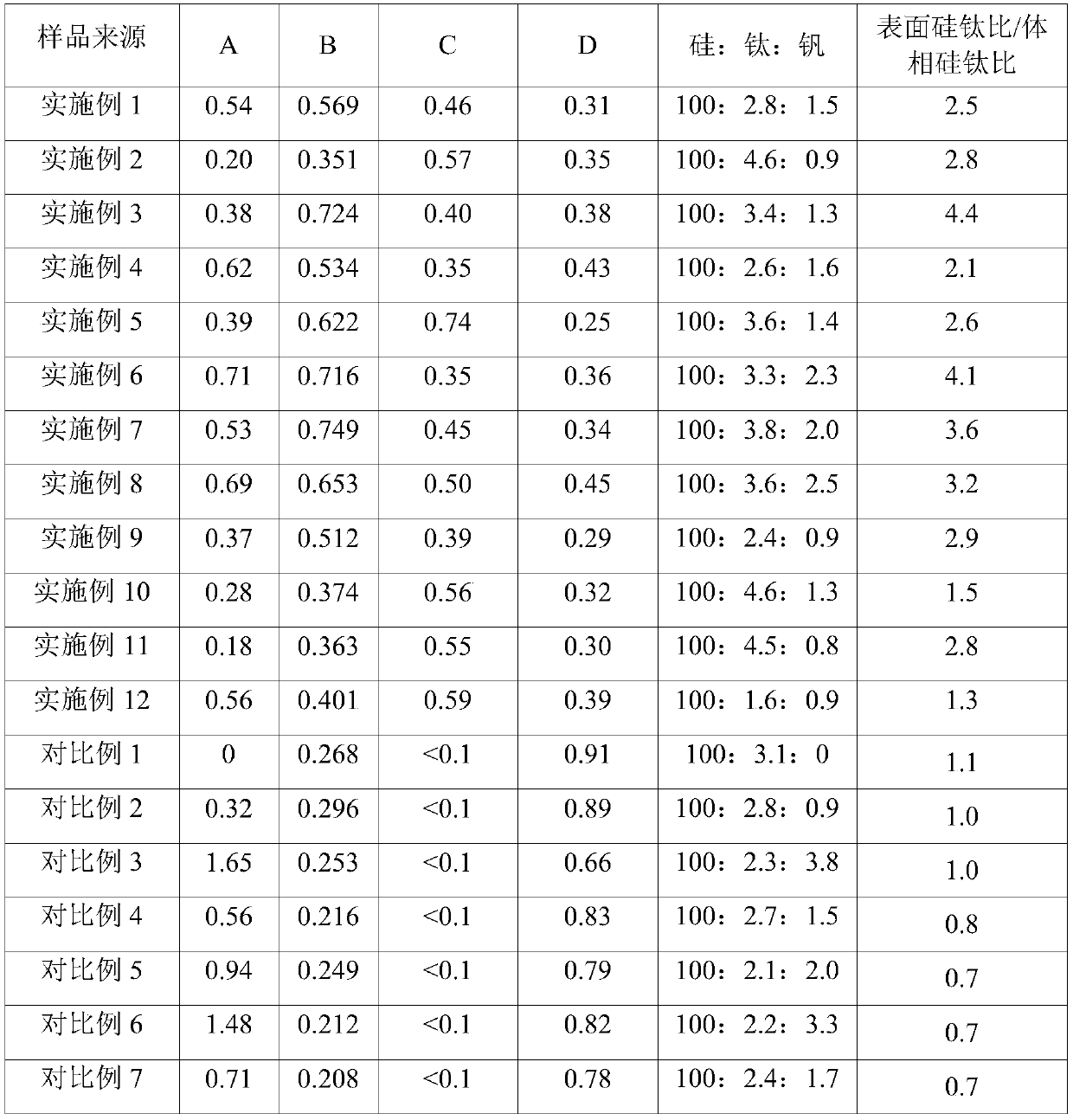

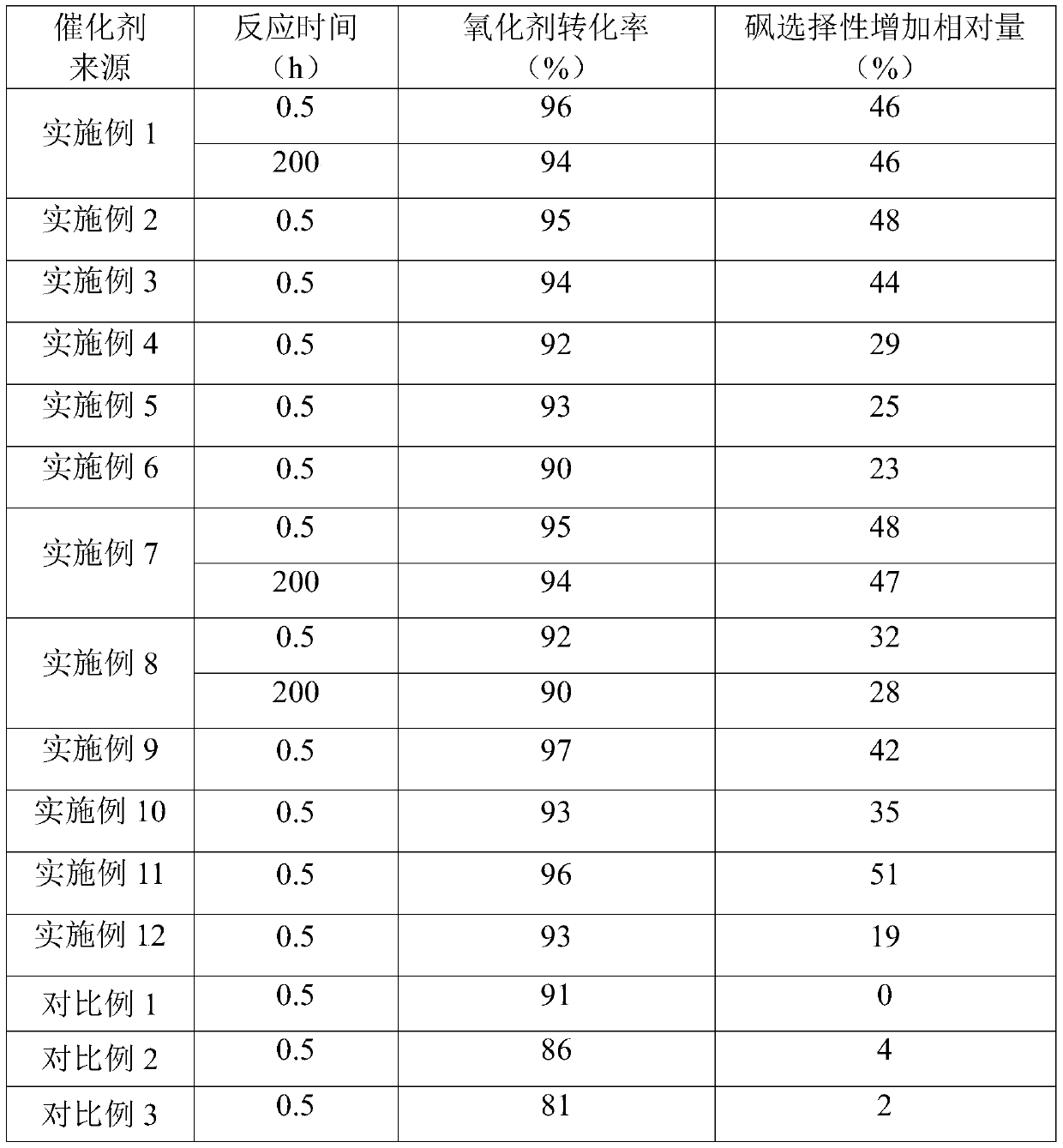

[0025] According to a preferred embodiment of the present invention, the molecular sieve satisfies nV / nTi=A, I 960 / I 800 =B, B=i(A+1)nTi, wherein 0.1960 Infrared absorption spectrum of molecular sieve at 960cm -1 Absorption intensity in the vicinity, I 800 Infrared absorption spectrum of molecular sieve at 800cm -1 The absorption intensity at the vicinity is preferably 0.2<A<5, 0.3<B<0.8. In this way, it can be more beneficial to the diffusion of reactants and product molecules in the catalytic oxidation reaction, not only can further improve the conversion rate of the oxidant, but also can more effectively adjust the selectivity of the target product. For example, when used in a thioether oxidation reaction, the conversion rate of the oxidant peroxide can be further improved, and the selectivity of the target product sulfone can be more effectively adjusted.

[0026] In the present invention, the absorption intensity of the infrared absorption spectrum of the molecular s...

Embodiment 1

[0125] This example illustrates the methods and products provided by the invention.

[0126] At normal temperature (20°C, the rest of the comparative examples are the same as the examples) and normal pressure (0.1MPa, the rest of the comparative examples are the same as the examples), the deactivated cyclohexanone oximation catalyst SH-2 and 1mol / L hydrochloric acid The aqueous solution was mixed and beaten, and then the mixed slurry was mixed and stirred at 80°C for 12 hours; after solid-liquid separation, the solid, vanadium source ammonium metavanadate, titanium source titanium sulfate and sodium hydroxide aqueous solution (pH 12) were mixed and the mixed solution was Put it into a stainless steel sealed reaction kettle, and treat it at 170°C for 12 hours, wherein, the mass composition of the material is an inactivated cyclohexanone oximation catalyst: titanium source: vanadium source: acid: alkali: water = 100: 1: 1: 10: 5:250, deactivated cyclohexanone oximation catalyst ...

Embodiment 2

[0131] This example illustrates the methods and products provided by the invention.

[0132] At normal temperature and pressure, first mix the deactivated cyclohexanone oximation catalyst SH-3 with 5mol / L hydrochloric acid solution for beating, then mix and stir the mixed slurry at 60°C for 1 hour; after solid-liquid separation, separate the solid, Vanadium tetrachloride as a source of vanadium, tetrabutyl titanate as a source of titanium, and tetrapropylammonium hydroxide aqueous solution (pH 10) are mixed, and the mixture is put into a stainless steel sealed reaction kettle, and treated at 150°C for 12 hours. Composed of deactivated cyclohexanone oximation catalyst: titanium source: vanadium source: acid: alkali: water = 100:2:0.5:15:15:200, the deactivated cyclohexanone oximation catalyst is SiO 2 In terms of acid, H + In terms of alkali in OH - In terms of titanium source as TiO 2 count. Then the product was recovered according to the method of Example 1 to obtain a mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com