Horizontal feed stirrer rotor

A mixer and feed technology, which is applied to mixers with rotating agitation devices, mixers, dissolving, etc., can solve the problems of substandard mixing uniformity, heavy weight of the rotor, and increased input costs, so as to ensure the uniformity of feed mixing and work The effect of load reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the drawings and specific embodiments.

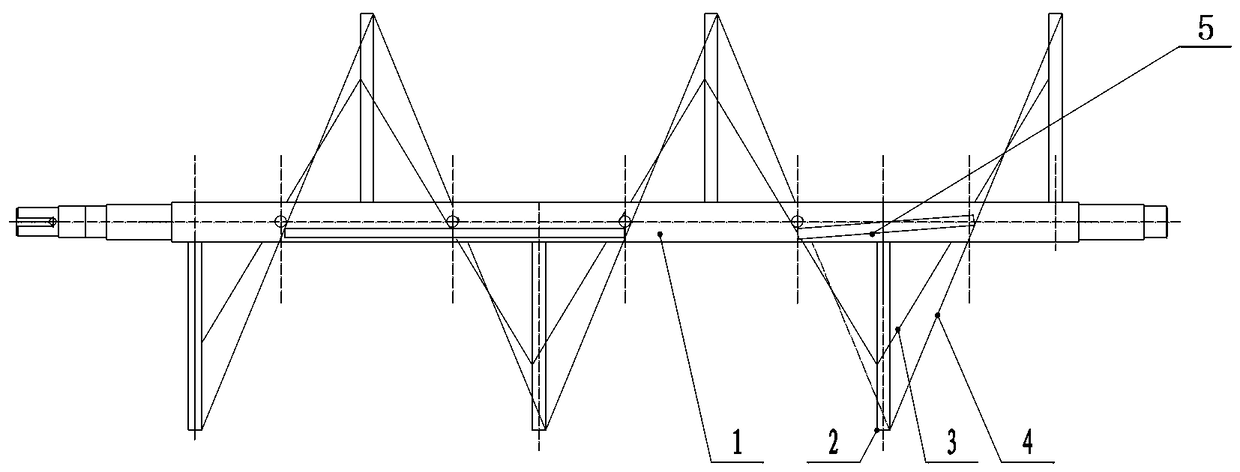

[0019] From figure 1 , 2 It can be seen that this is a 500kg horizontal feed mixer rotor, which is composed of a main shaft, a support rod, and a spiral blade. The support rod is equidistantly distributed and welded on the main shaft. The diameter of the blade is 550~650mm, the diameter of the outer helical blade is 800~900mm, the length of the main shaft is 2200~2210 mm, and the width of the inner helical blade and the outer helical blade is 30. There are 11 support rods. In the present invention, 5 transverse reinforcement rods are welded between the inner helical blade and the outer helical blade, and each length is 200 mm, which are used to enhance the strength of the helical blade.

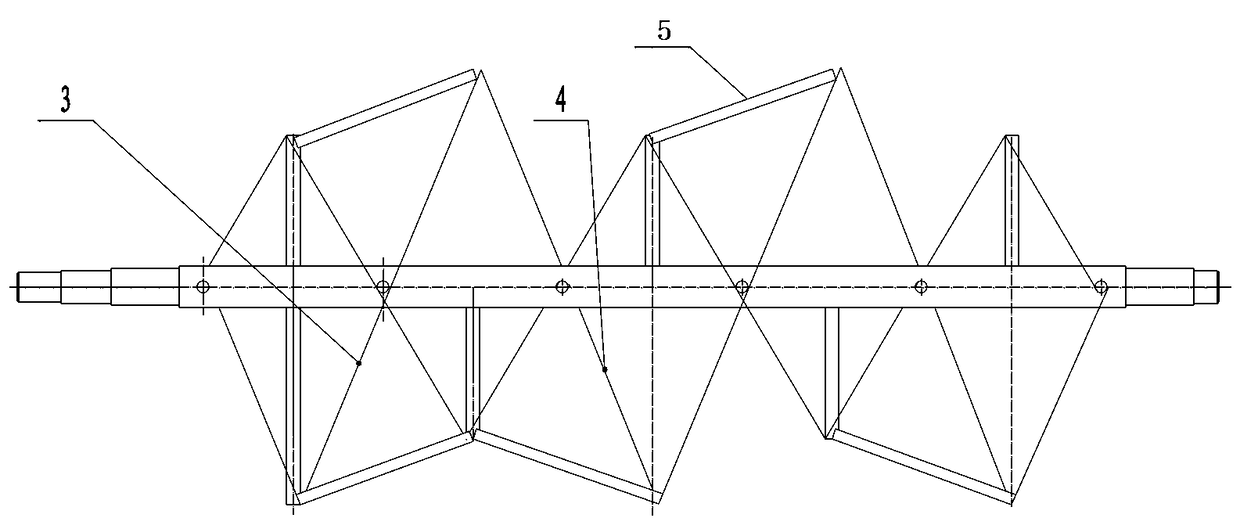

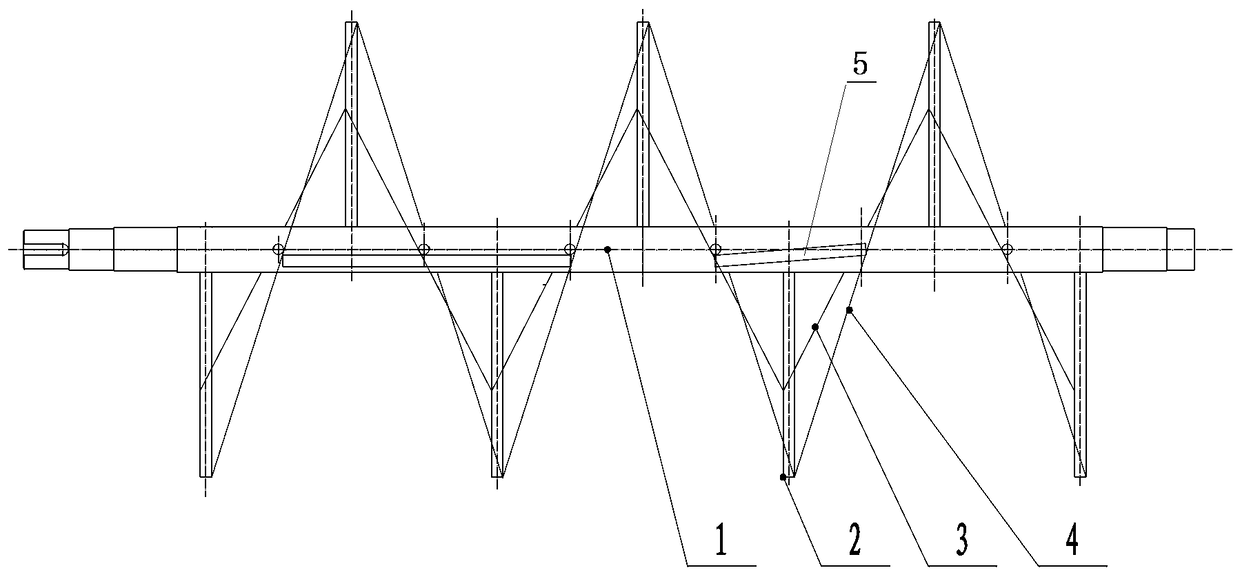

[0020] From image 3 , 4 It can be seen that this is a 1000kg horizontal feed mixer rotor, which is composed of a main shaft, a support rod, and a spiral blade. The support r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com