Sand belt adjusting mechanism

An adjustment mechanism and sand belt technology, which is applied to percussion instruments, instruments, musical instruments, etc., can solve problems such as non-linear adjustment, lower product quality, and sand belt deformation, so as to achieve good user experience and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

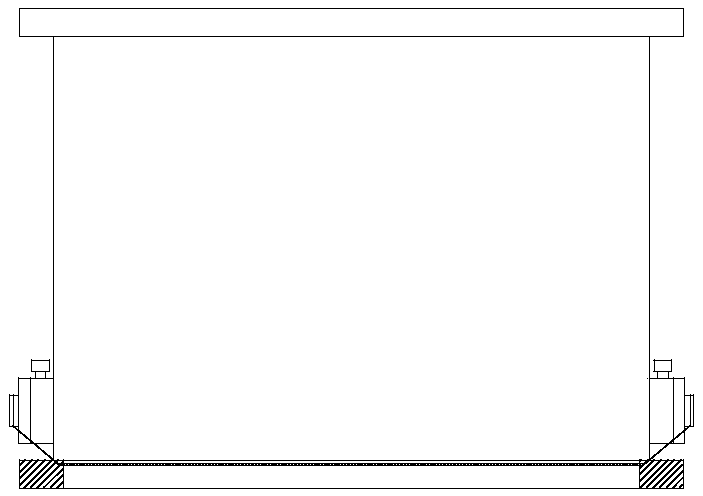

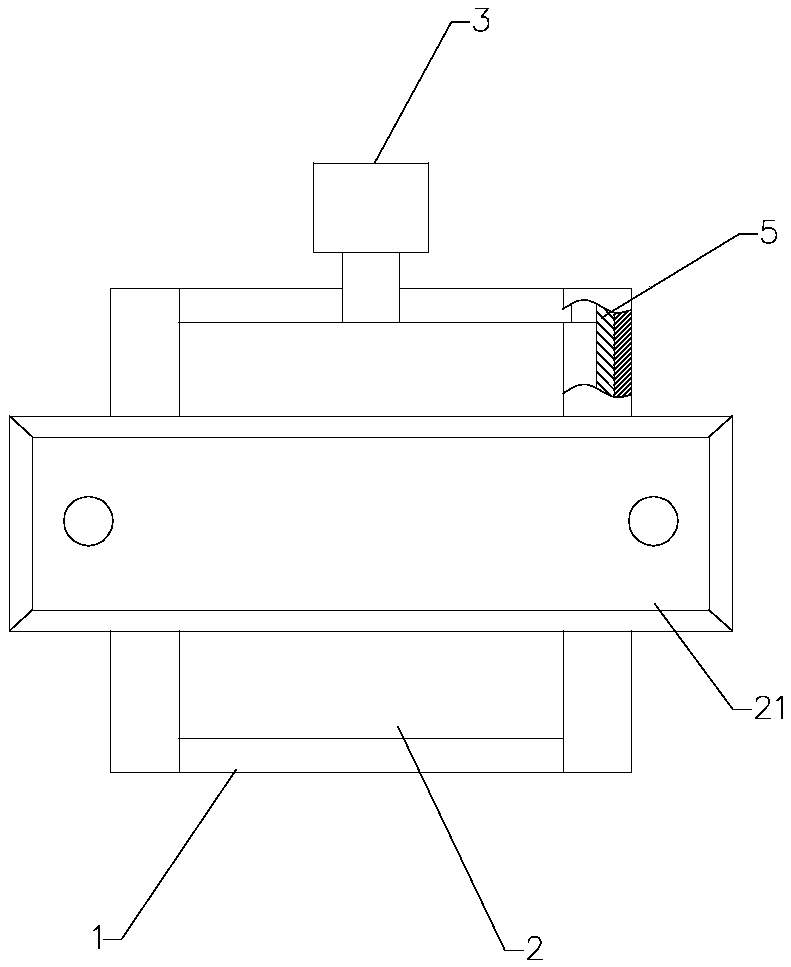

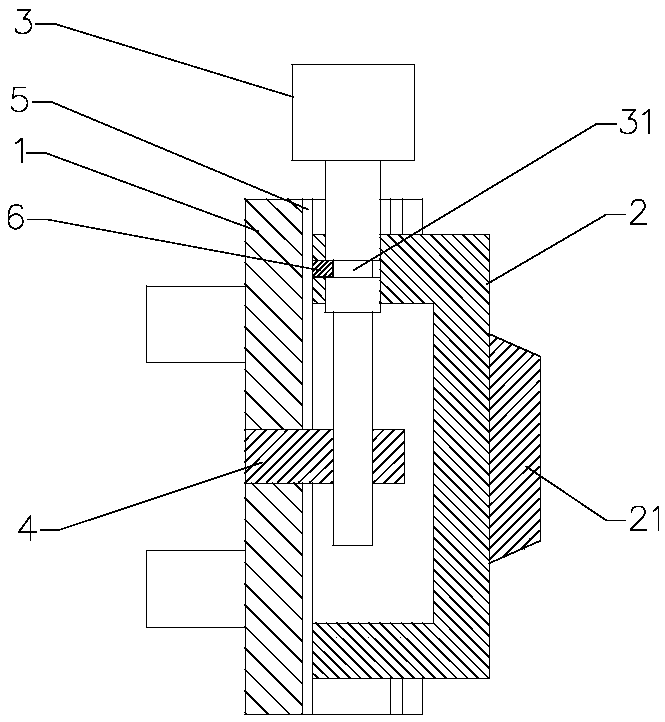

[0013] see Figure 1 to Figure 3 The sand belt adjustment mechanism of the present invention includes two structurally consistent adjustment members that are symmetrically arranged on the drum cavity and respectively connected to the two ends of the sand belt. The two-way adjustment of the sand belt can be realized by adopting two adjusting parts arranged at both ends of the sand belt.

[0014] The adjusting member includes a fixing base 1, a sliding cover 2 and an adjusting bolt 3, the fixing base 1 is fixedly installed on the drum cavity, specifically, the fixing base 1 is fixedly connected with the drum cavity by two bolts. The fixing base 1 is also provided with a connecting block 4 , and a threaded hole matching the adjusting bolt 3 is formed through the connecting block 4 .

[0015] The sliding cover 2 can be slidably installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com