Fault diagnosis of rotating machinery based on one-dimensional depth residual convolution neural network

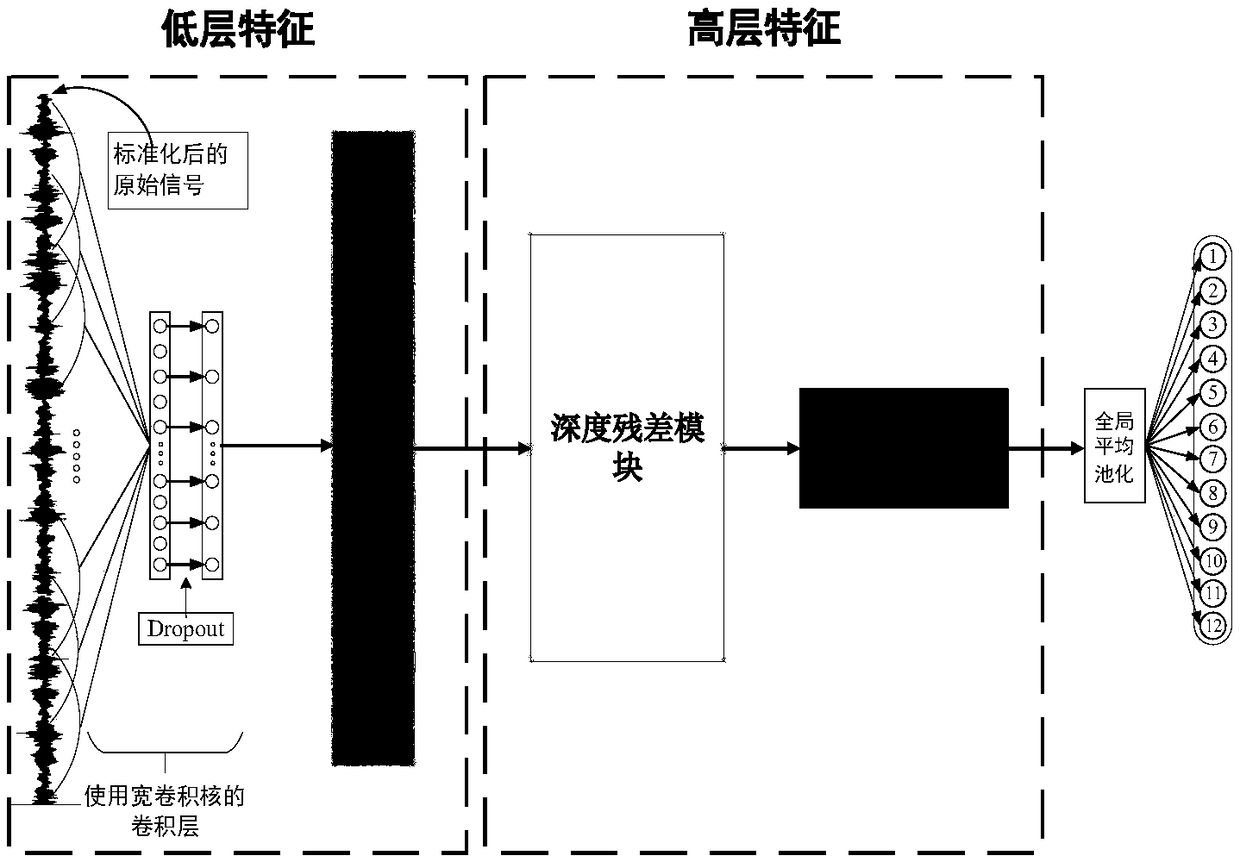

A technology of convolutional neural network and rotating machinery, applied to biological neural network models, neural architectures, computer components, etc., can solve problems such as difficult to learn features, easy to cause misjudgment, poor domain adaptability, etc., and achieve improved feature The effect on learning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] For the convenience of description, the relevant technical terms appearing in the specific implementation are explained first:

[0050] ReLU(Rectified Liner Units): corrected linear unit;

[0051] BN (Batch Normalization): batch normalization.

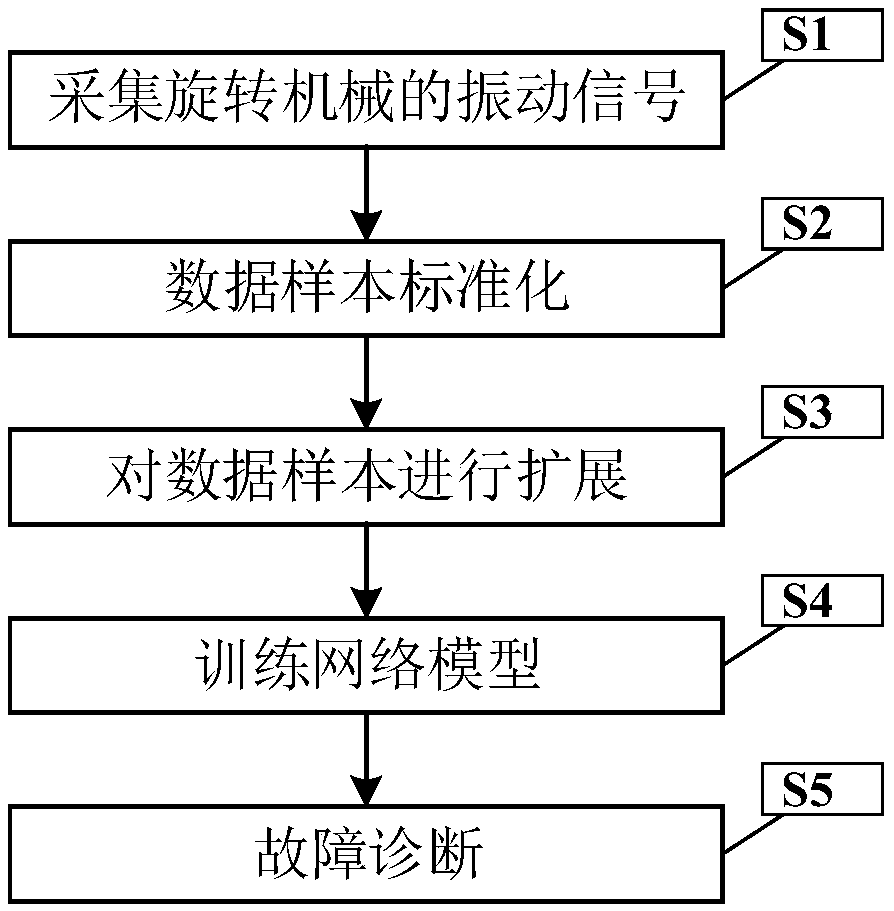

[0052] figure 1 It is a flow chart of a method for diagnosing a rotating machinery fault based on a one-dimensional deep residual convolutional neural network in the present invention.

[0053] In this example, if figure 1 As shown, the present invention is based on a one-dimensional deep residual convolutional neural network fault diagnosis method for rotating machinery, comprising the following steps:

[0054] S1. Acquisition of vibration signals of rotating machinery

[0055] Acquisition of rotating machinery with different faults at a sampling frequency f s Acceleration vibration signals x[n] at 9 o'clock and 12 o'clock under different operating speeds, different vertical loads and axial loads m , to obtain the acceler...

example

[0080] In this implementation case, relying on a certain bearing test bench, such as Figure 7 shown. The specific relevant information is as follows:

[0081] The wheel set bearing fault diagnosis test bench is composed of a driving motor, a belt drive system, a vertical loading device, a lateral loading device, two fan motors and a control system. The vertical and lateral load loading device is designed to simulate the axial and lateral loads carried by the wheel set bearings in actual train operation. Two fan motors can generate wind that is opposite to the train running direction. Two accelerometers are used to ensure that the vibration of the wheel set bearing in the horizontal direction and vertical direction can be detected, and the signal acquisition frequency is set to 5120Hz.

[0082] We machined bearings in 12 different health conditions. Table 1 lists the specific information of 12 kinds of faults, where the labels are respectively C1, C2, C3, ..., C12. In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com