Automatic laying device for similar material simulation test and application method thereof

A technology of similar materials and simulation tests, applied in the field of automatic paving devices, can solve the problems of high labor intensity, increased workload, uneven stirring, etc., and achieve the effects of improving molding quality, improving molding speed and quality, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

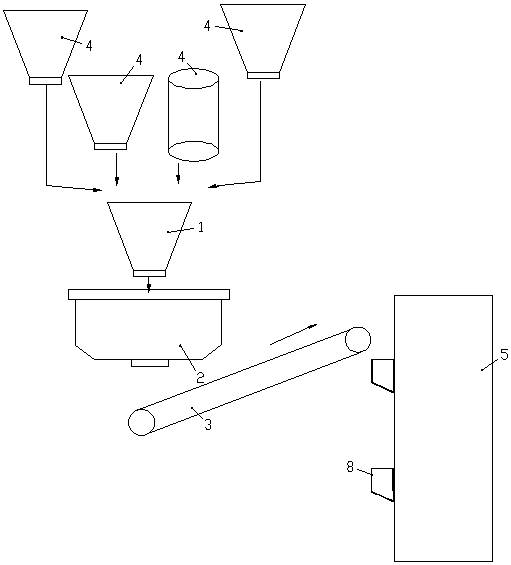

[0022] Such as Figure 1-3 Shown, the automatic pavement device that is used for similar material simulation test of the present invention comprises weighing hopper 1, agitator 2, lifting type belt conveyor 3, similar material test box and several feed bins 4, the number of several feed bins 4 The discharge port is connected with the feed port of the weighing hopper 1, the discharge port of the weighing hopper 1 is connected with the feed port of the mixer 2, the discharge port of the mixer 2 is connected with the feed end of the lifting belt conveyor 3, and the lifting The discharge end of the type belt conveyor 3 is connected with a similar material test chamber.

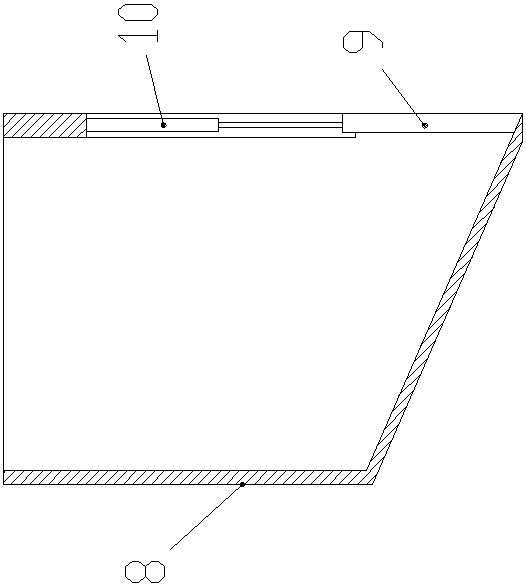

[0023] The similar material test box includes a hydraulic compaction mechanism and a test frame 5, the hydraulic compaction mechanism is arranged on the top of the test frame 5, and several guard plates 6 are respectively provided on the front side and the rear side of the test frame 5, and several guard plates 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com