Seed drying, coating and processing integrated machine

An all-in-one machine and dryer technology, applied in dryers, seed coating/seed dressing, drying and other directions, can solve the problems of fresh seeds being intolerant of storage, consuming manpower and time, and unable to dry seeds, etc. Save time and effort, avoid waste, and improve germination rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

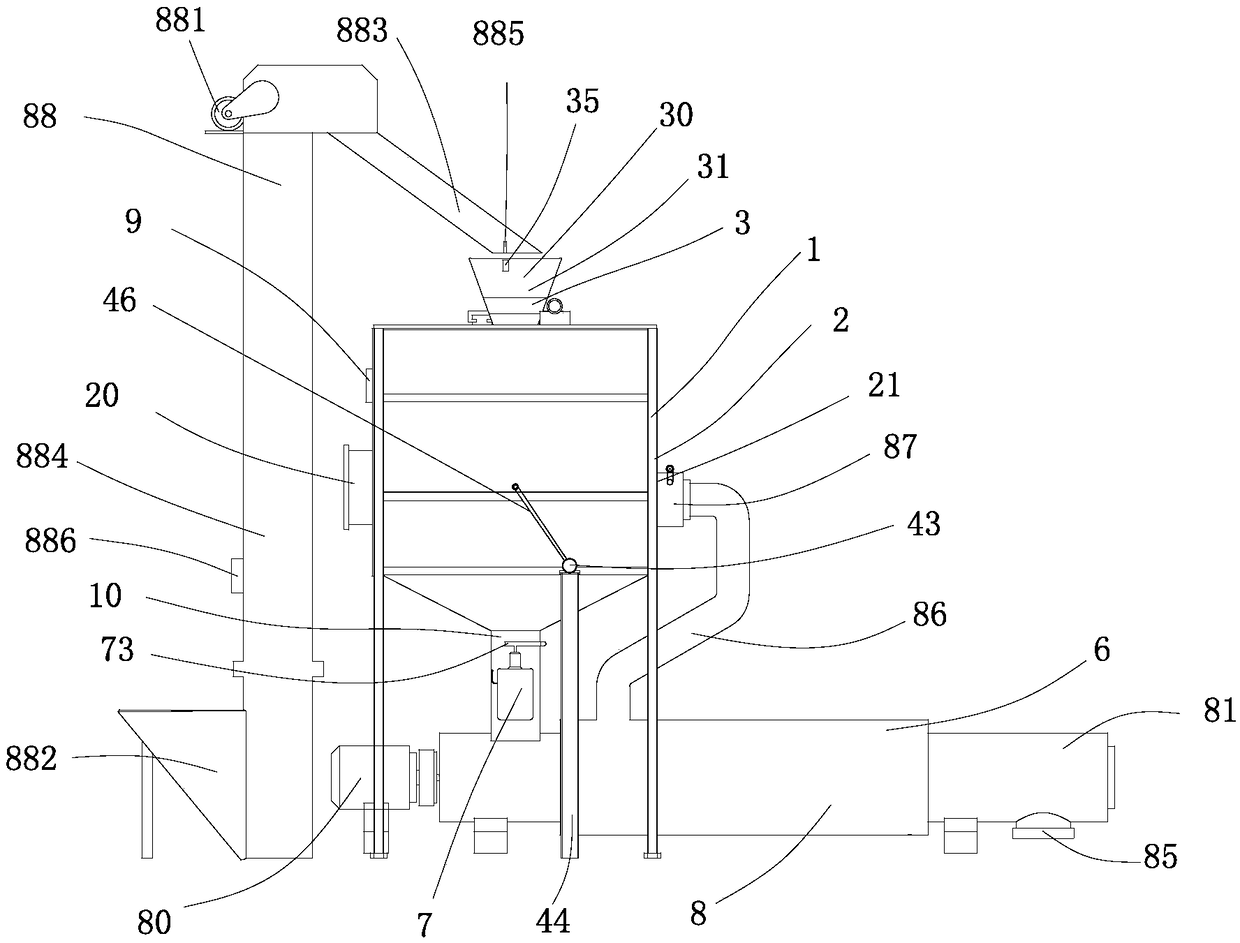

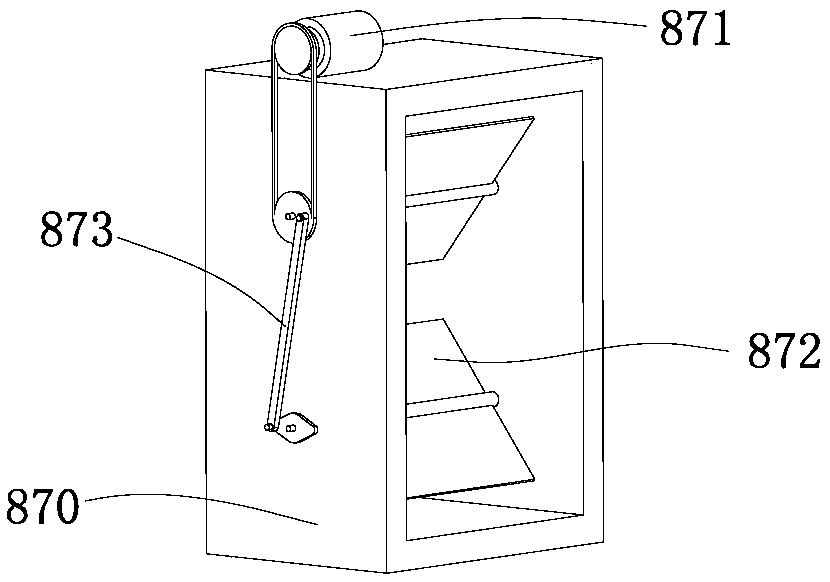

[0044] as attached figure 1 to attach Figure 22 As shown, the present invention mainly includes a dryer 1, a coating machine 6 and a controller 9. The dryer 1 mainly includes a box body 2, a material spreading mechanism 3, a material receiving mechanism 4 and a material discharging mechanism 5. The coating machine 6 mainly includes a spraying mechanism 7 and an auger mechanism 8 arranged at the lower end of the spraying mechanism.

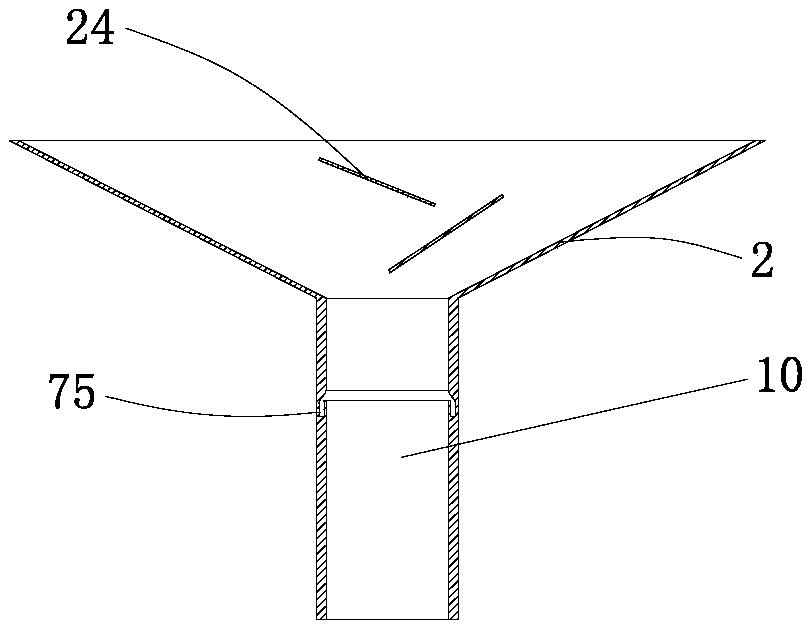

[0045] The box body 2 has an air inlet 10 and an air outlet 21, the air inlet 10 is connected to an external hot air supply mechanism, and the hot air enters the inside of the box body 2 from the air inlet 10 to dry the seeds and then discharges from the air outlet.

[0046] like Figure 4 As shown, the material receiving mechanism 4 mainly includes a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com