Semi-contact curved surface three-dimensional size measuring device and measuring method thereof

A measuring device and a three-dimensional dimension technology, which is applied in the field of semi-contact arc surface three-dimensional dimension measuring devices, can solve the problems of inability to measure continuous curved surface measurement efficiency, low measurement accuracy, and difficulty in precise positioning, so as to avoid differences in measurement results, and the device Simple structure and the effect of improving measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

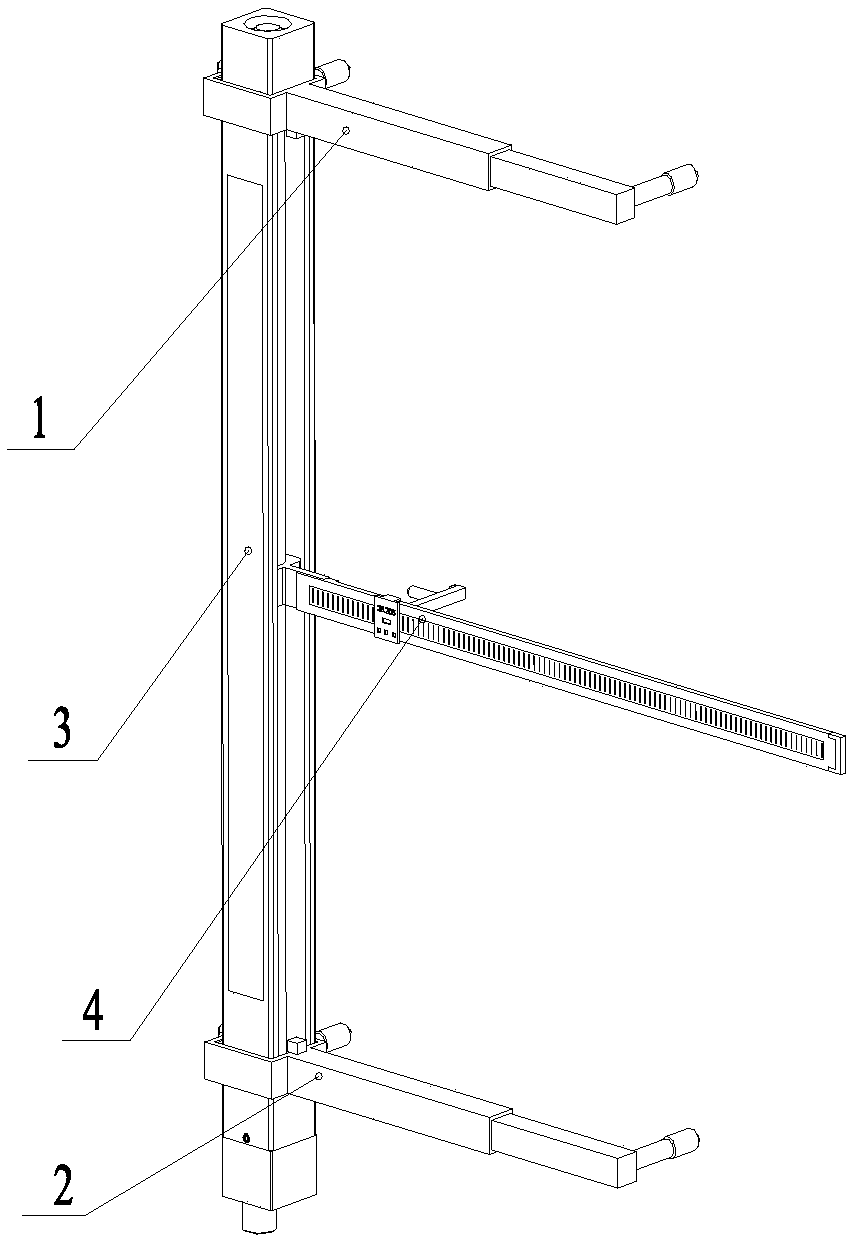

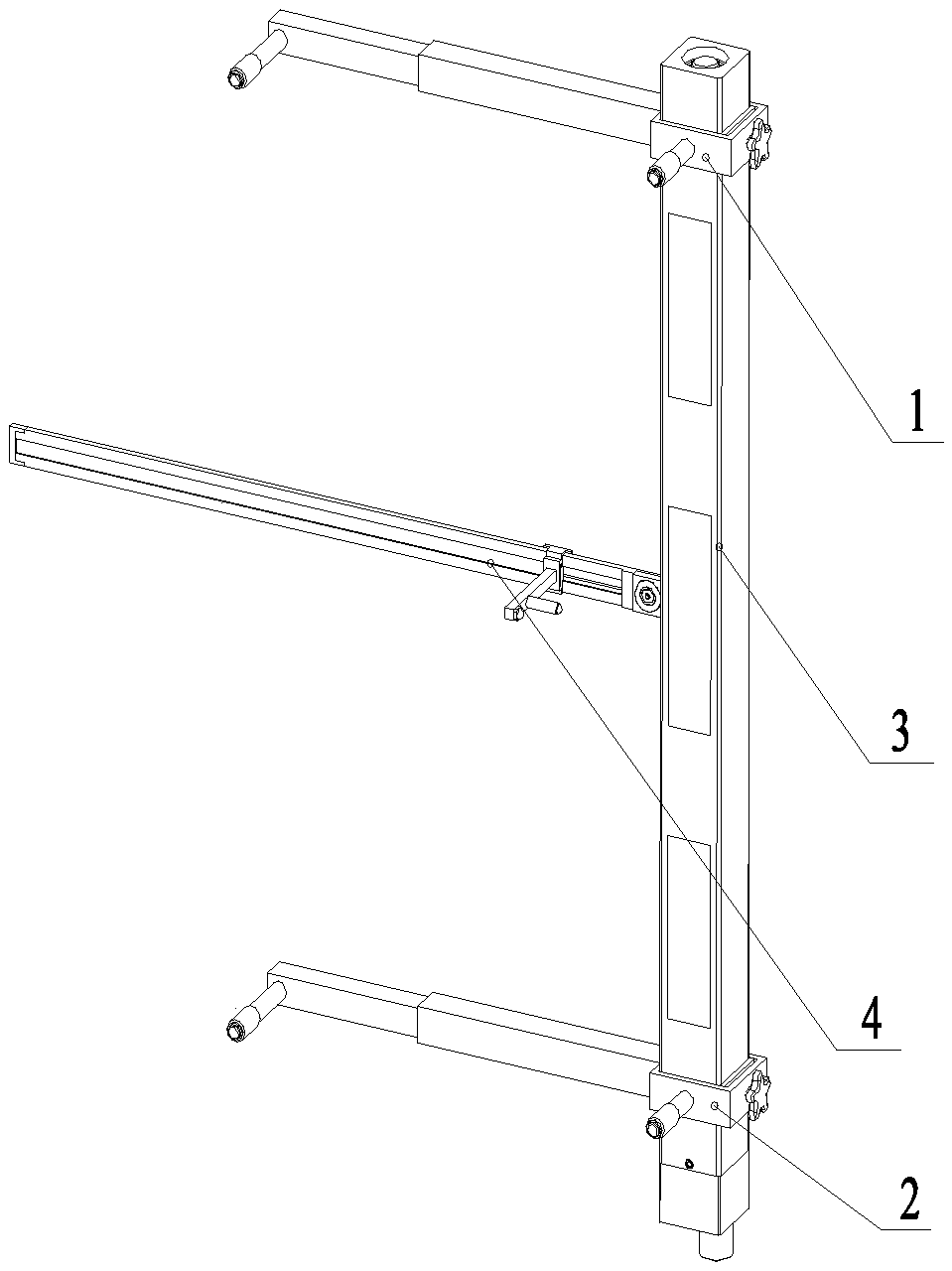

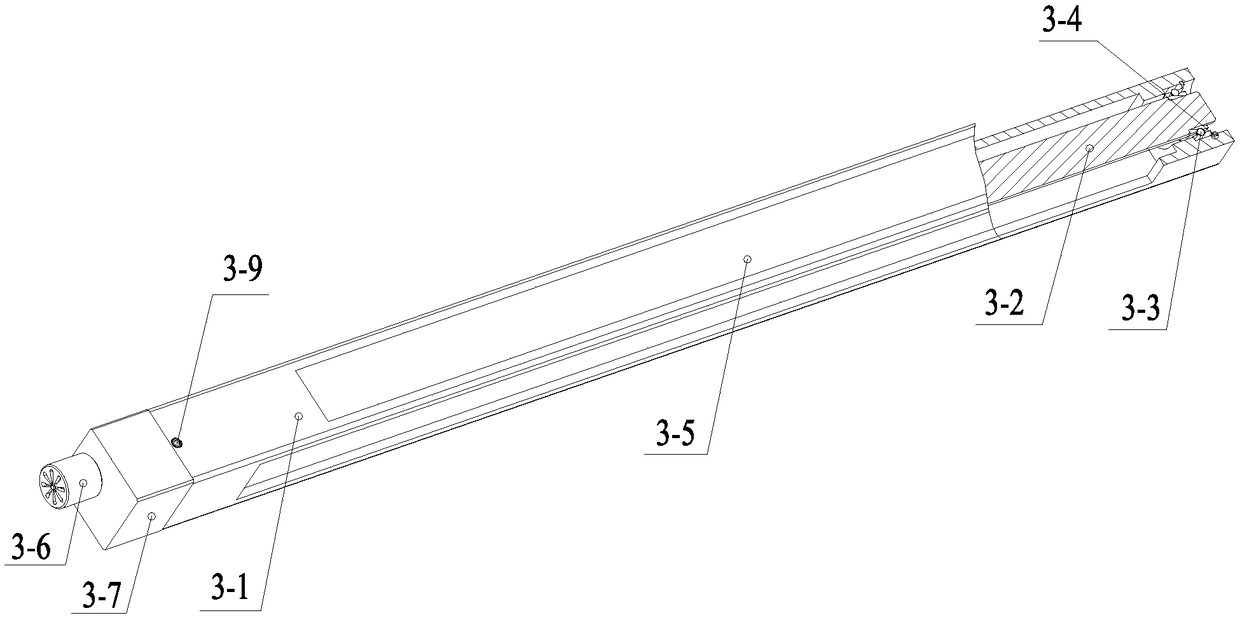

[0047] Such as Figure 1 to Figure 23 As shown, the semi-contact arc surface three-dimensional dimension measuring device of the present invention includes: an upper fixed claw 1, a lower fixed claw 2, a driving fixture 3 and a capacitive laser measuring device 4; the upper fixing claw 1 is installed on the driving fixture side, the lower fixed claw 2 is installed on the lower side of the driving and fixing device, the structure of the upper fixed claw 1 and the lower fixed claw 2 are the same, and the two fixed claws are the fixing structures of the measuring device of the present invention, which can fix the measuring device on the measured arc Around the surface; the two fixed claws move up and down according to the measurement requirements of the measured arc surface to adjust the clamping position, and adapt to the clamping requirements of different meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com