Wall face finishing coat scraping device for building decoration

A scraping device and topcoat technology, applied in building maintenance, construction, building construction, etc., can solve the problems of low scraping efficiency, physical health hazards, and large dust on wall topcoats, and achieve the goal of improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

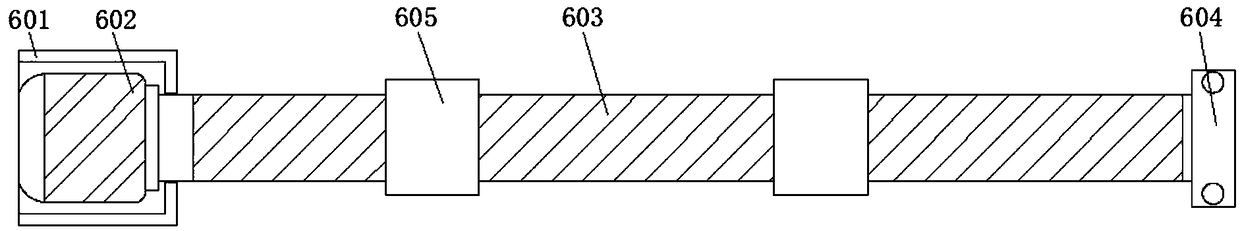

[0033] see Figure 1-7, a wall surface paint scraping device for architectural decoration, including a base plate 1, universal wheels 2 are fixedly installed at the four corners of the bottom of the base plate 1, with a locking device on the universal wheels 2, which can limit the movement of the universal wheels 2, the base plate 1 Both sides of the top are fixed with electro-hydraulic push rods 3, which are suitable for reciprocating up and down movement, and can drive the wall brushing mechanism 8 and top paint scraping mechanism 9 to move up and down. Transmission, sensitive action, stable operation, can effectively buffer the external impact force, and at the same time improve the bearing capacity, the top of the two electro-hydraulic push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com