Adjustable fixing mechanism of windproof tower crane base

A fixed mechanism and adjustable technology, applied in the direction of cranes, transportation and packaging, etc., can solve the problems of waste of resources, removal of the base, difficult handling, shaking of the tower crane, etc., and achieve the effect of easy calibration of the direction of the tower body, convenient operation and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the drawings and specific embodiments.

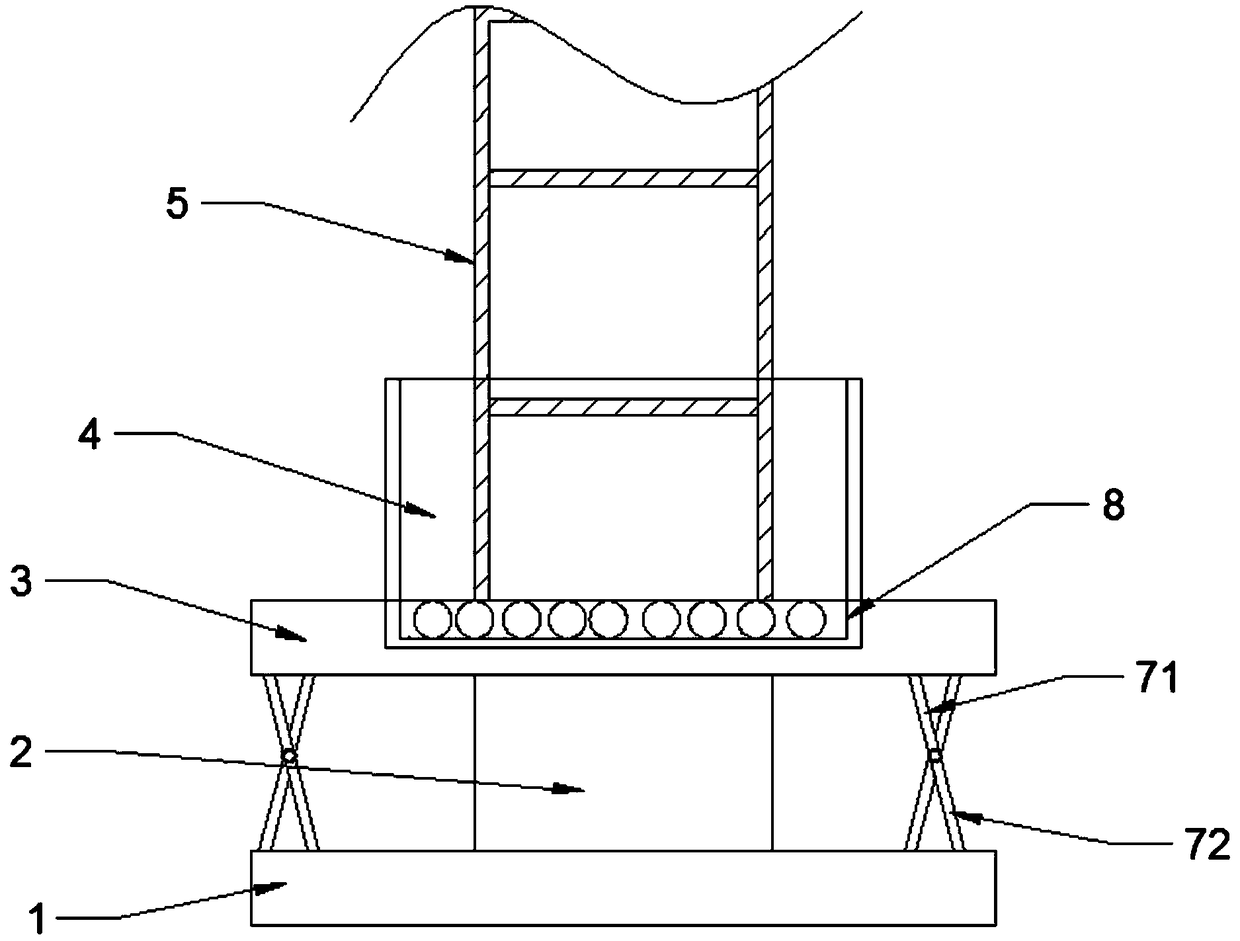

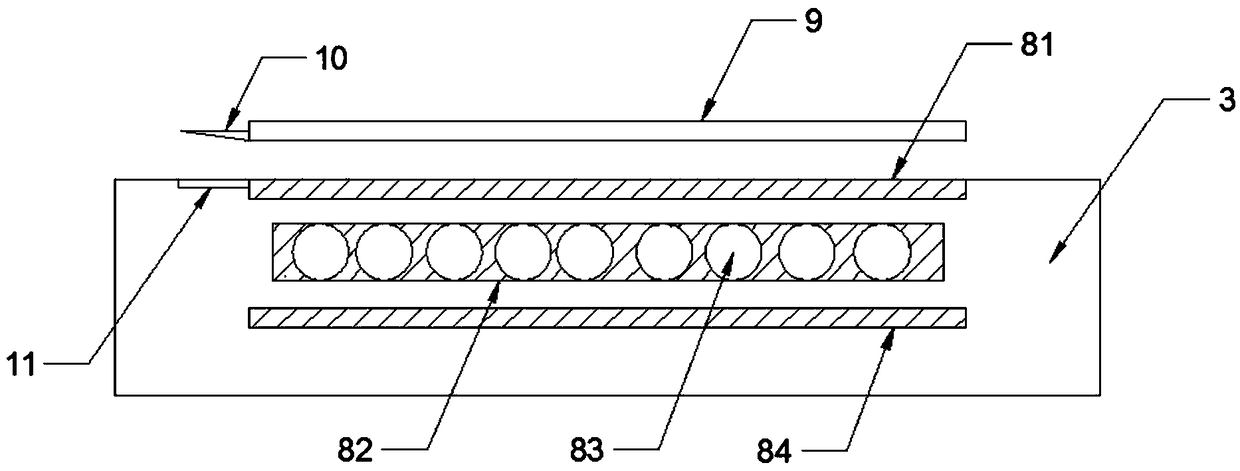

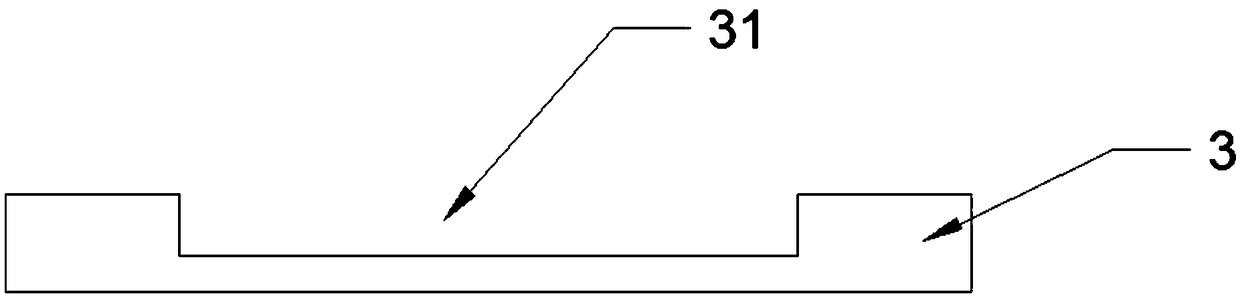

[0016] Such as figure 1 As shown, the adjustable fixing mechanism of the base of the windbreak tower crane includes a base 1, a mounting column 2, a bottom plate 3, a base 4, and a tower body 5 sequentially arranged from bottom to top, and the base 1 and the bottom plate 3 are connected around by studs. A first connecting rod 71 and a second connecting rod 72 are intersected between the top of the base 1 and the bottom of the base 4, and the intersection of the first connecting rod 71 and the second connecting rod 72 is movably connected by a pin. Both ends of the first pull rod 71 and the second pull rod 72 are connected to the bottom plate 3 and the base 1 by studs, and a rotating mechanism 8 for driving the tower body 5 to rotate is arranged between the bottom plate 3 and the tower body 5.

[0017] When the wind resistance of the site environment is small or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com