Intelligent logistics handling equipment for docking with cargo ship and working method thereof

A technology for handling equipment and intelligent logistics, applied in transportation and packaging, loading/unloading, etc., can solve problems such as hidden dangers, high labor costs, and floating, and achieve the effects of improving stability, safe transfer, and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

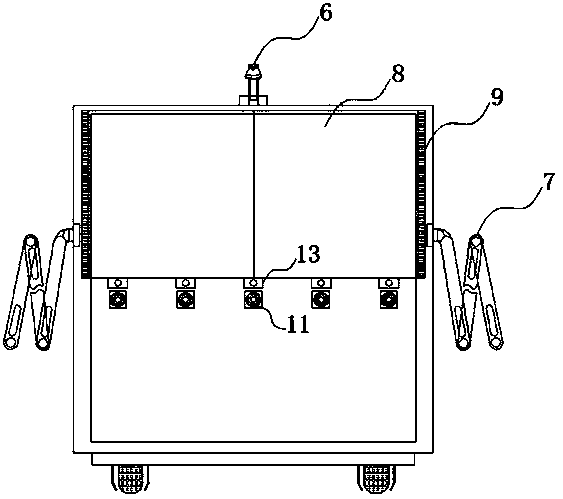

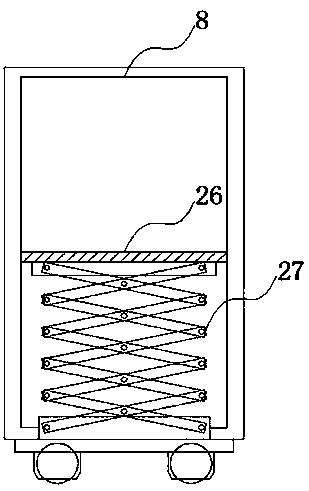

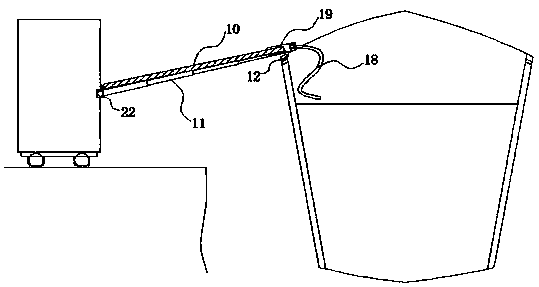

[0049] Such as Figure 1-11 As shown, this embodiment provides an intelligent logistics handling equipment docked with a cargo ship, including a handling mechanism, a connecting mechanism, a moving mechanism, and a control mechanism. The control mechanism includes a processor 1, a driving device 2, a positioning device 3, and a navigation device 4 And storage device 5, processor 1 is connected with driving device 2, positioning device 3, navigation device 4 and storage device 5 respectively, processor 1 is also connected with freight ship control system, and positioning device 3 is used for obtaining the position information of transport mechanism and The location information is sent to the processor 1, the navigation device 4 is used to generate a moving route of the moving mechanism and sends the moving route to the processor 1, and the storage device 5 is used to store the transportation records of the transportation mechanism.

[0050] The conveying mechanism includes a ca...

Embodiment 2

[0068] Such as Figure 12 As shown, the present embodiment provides a working method of an intelligent logistics handling device docked with a cargo ship, including the following working steps:

[0069] a) The processor 1 receives the unloading signal sent by the control system of the cargo ship, and the unloading signal includes the first position information of the cargo ship;

[0070] b) The positioning device 3 acquires the second position information of the transport mechanism and sends the second position information to the processor 1, the processor 1 imports the second position information and the second position information into the navigation device 4, and the navigation device 4 generates the second position information to the moving route of the first location information and sending the moving route to the processor 1;

[0071] c) The processor 1 outputs a moving signal to the driving device 2, and the driving device 2 drives the moving mechanism to move accordin...

Embodiment 3

[0089] Also include before step i:

[0090] The split detection device 28 moves to the cargo ship and is located in front of the connecting mechanism, which performs safety detection on the items to be transported and sends the detection results to the processor 1;

[0091] The processor 1 judges whether the item includes dangerous objects according to the detection result;

[0092] If so, remove the item.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com