Welding strip pulling compressing device and method and series welding machine

A welding ribbon and equipment technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems affecting product quality, low production efficiency, and easy detachment of welding ribbon, so as to improve welding accuracy, improve work efficiency, The effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

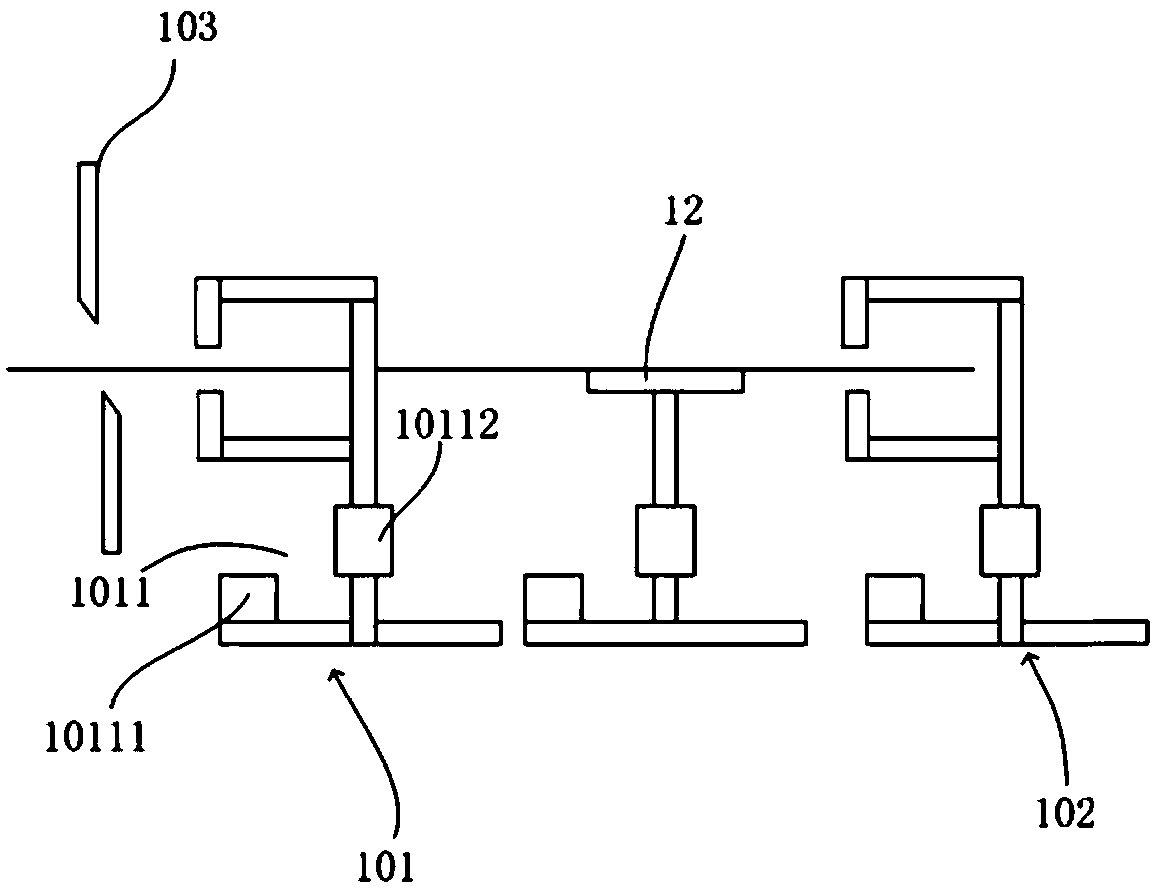

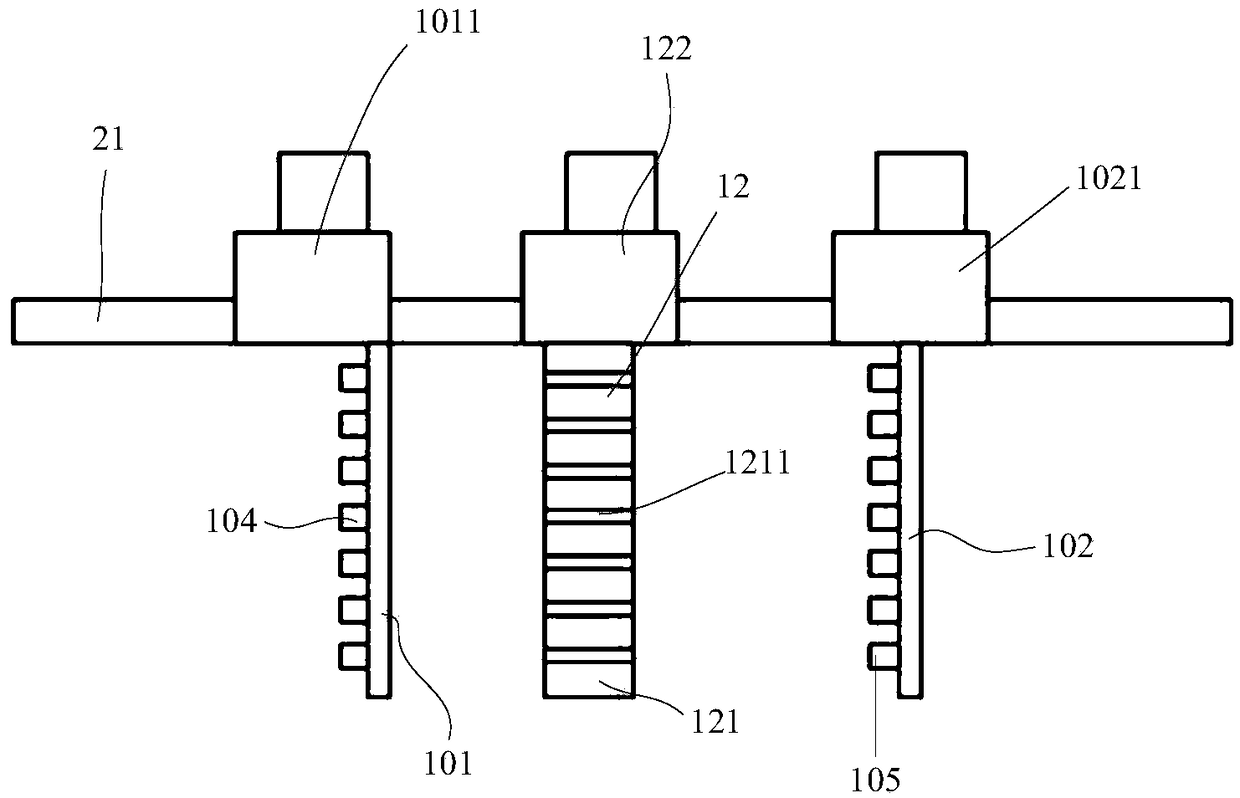

[0055] figure 1 It is a front structural schematic diagram of Embodiment 1 of the traction part in the strip traction and compaction equipment of the present invention. Fig. 2 is a top view structural diagram of Embodiment 1 of the traction part of the strip traction and compaction equipment of the present invention. Such as figure 1 and figure 2 As shown, the pulling part of the ribbon pulling and compacting equipment includes a first pulling device 101 and a second pulling device 102 , and the second pulling device 102 is installed behind the first pulling device 101 .

[0056] In this embodiment, a guiding ribbon device 12 is provided between the first pulling device 101 and the second pulling device 102. The guiding ribbon device 12 includes a guiding plate 121 and a guiding moving mechanism 122. At least two a guide groove 1211.

[0057] In this embodiment, the first pulling device 101 includes a first moving mechanism 1011 and a welding belt mechanism 104, wherein t...

Embodiment 2

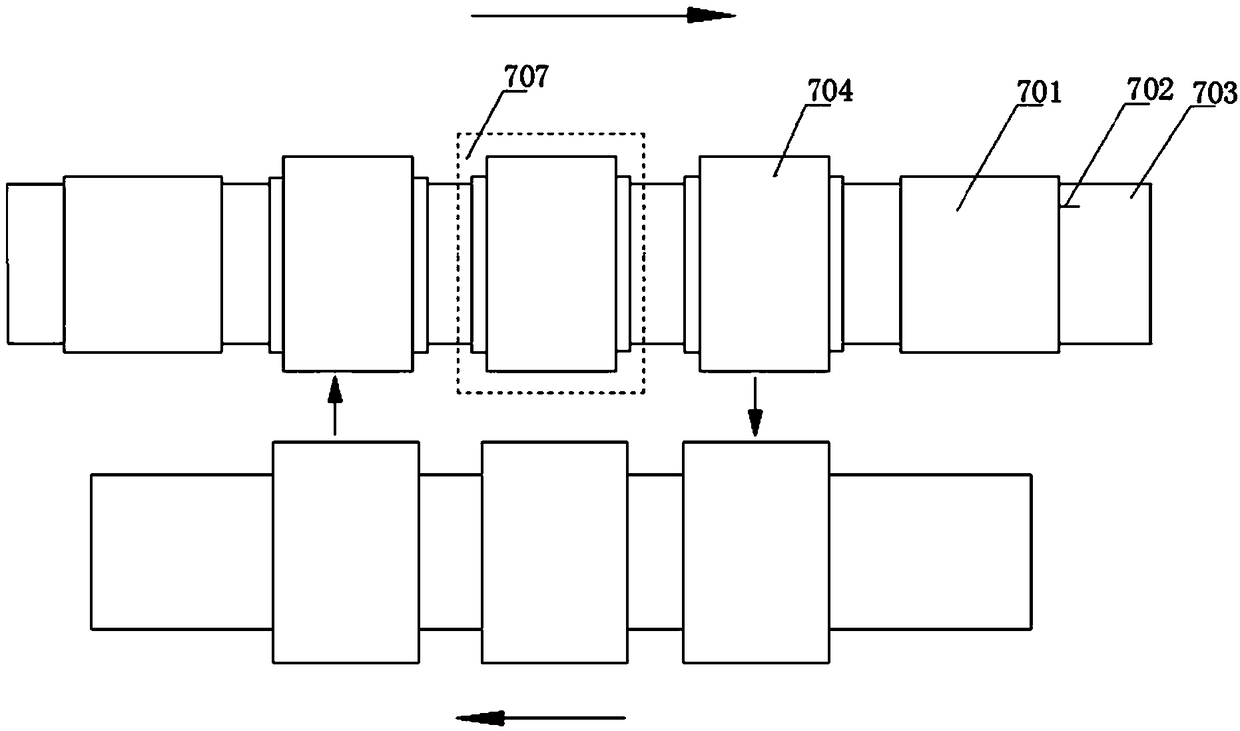

[0062] Such as Figure 3 to Figure 4 As shown in the figure, a battery sheet 701, a welding ribbon 702, a conveying line 703, a net pressing plate 704, a pressing pin 705, a spring 706 and a heating device 707 are shown in the figure. In this embodiment, the pressing pins 705 are arranged in a multi-row array, all of which are installed on the net pressing plate 704, and each row of pressing pins 705 forms a pressing pin group, and each pressing pin group corresponds to each welding ribbon 702 one by one, so that Ensure that each welding strip 702 has the same number of stress points as the number of pressing pins 705 in each row of pressing pins. The number of pressing pins 705 included in each row of pressing pins can be determined according to specific production requirements. For example, it can be Seven, eight, nine, ten, eleven, twelve or other applicable number. In addition, a spring 706 can be sleeved on each pressing pin 705 to form an elastic pressure, so as to ensu...

Embodiment 3

[0069] Such as Figure 5 and Figure 6 As shown, this embodiment includes a support plate 70010 , at least one support bar 70020 mounted on the support plate 70010 and at least one pressing pin 70030 mounted on the support bar 70020 . combined reference Figure 6 The indenter 70030 includes a sleeve 70031, an indenter head 70032 and a spring 70033, the upper end of the sleeve 70031 is fixed on the support bar 70020, the lower end of the sleeve 70031 is provided with a waist-shaped hole 70034, and the upper end of the indenter 70032 is provided with a Column pin 70035, column pin 70035 passes waist-shaped hole 70034, and spring 70033 is installed in the sleeve 70031.

[0070] Optionally, the column pin 70035 on the indenter head 70032 can be integrally formed when the indenter head 70032 is manufactured, or a through hole can be provided on the indenter head 70032, and the column pin 70035 is fixed on the indenter head 70032 through the through hole. Optionally, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com