Steel bar bender

A steel bar bending and steel bar technology, applied in the field of steel bar processing equipment, can solve the problems of high labor intensity of workers, and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

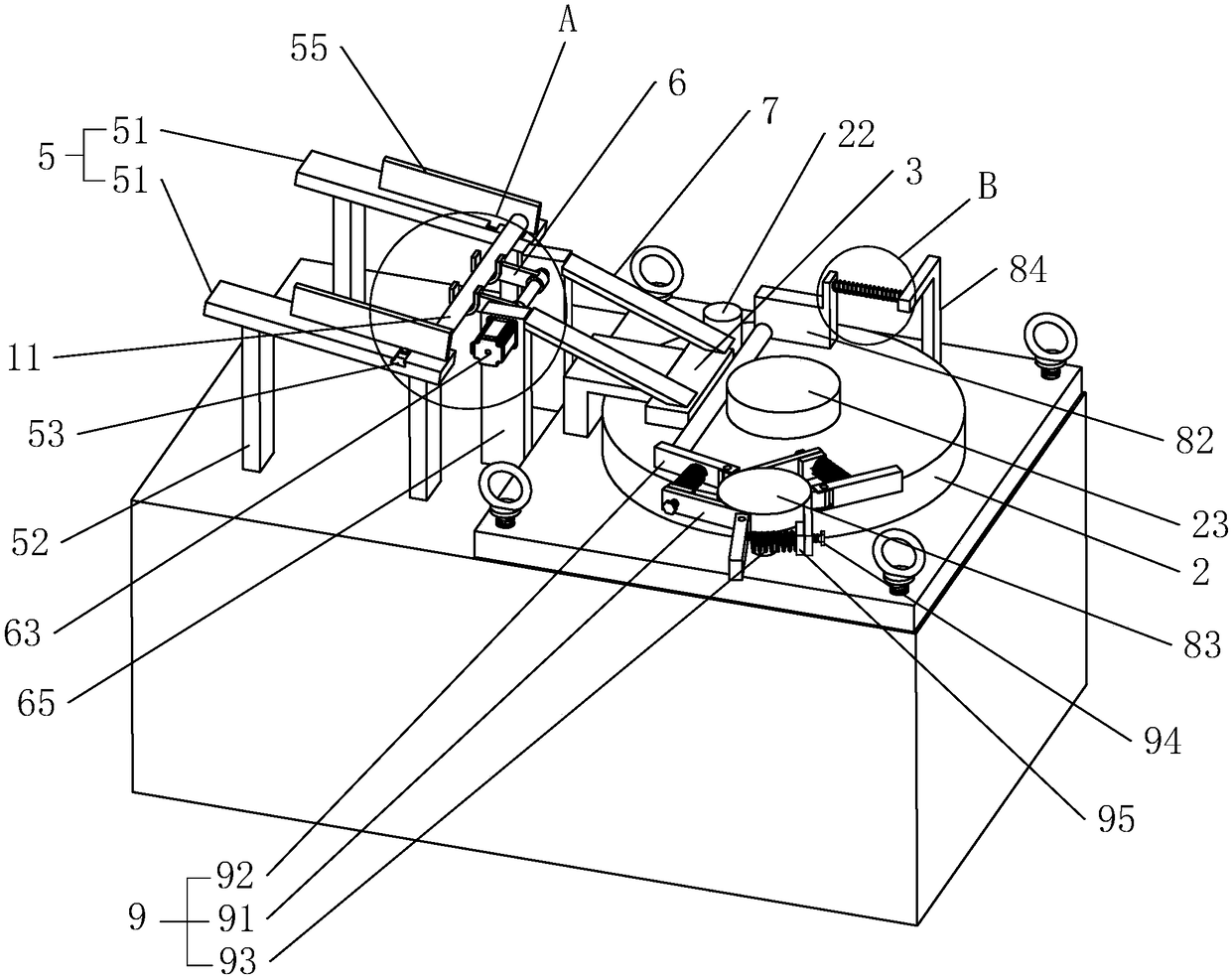

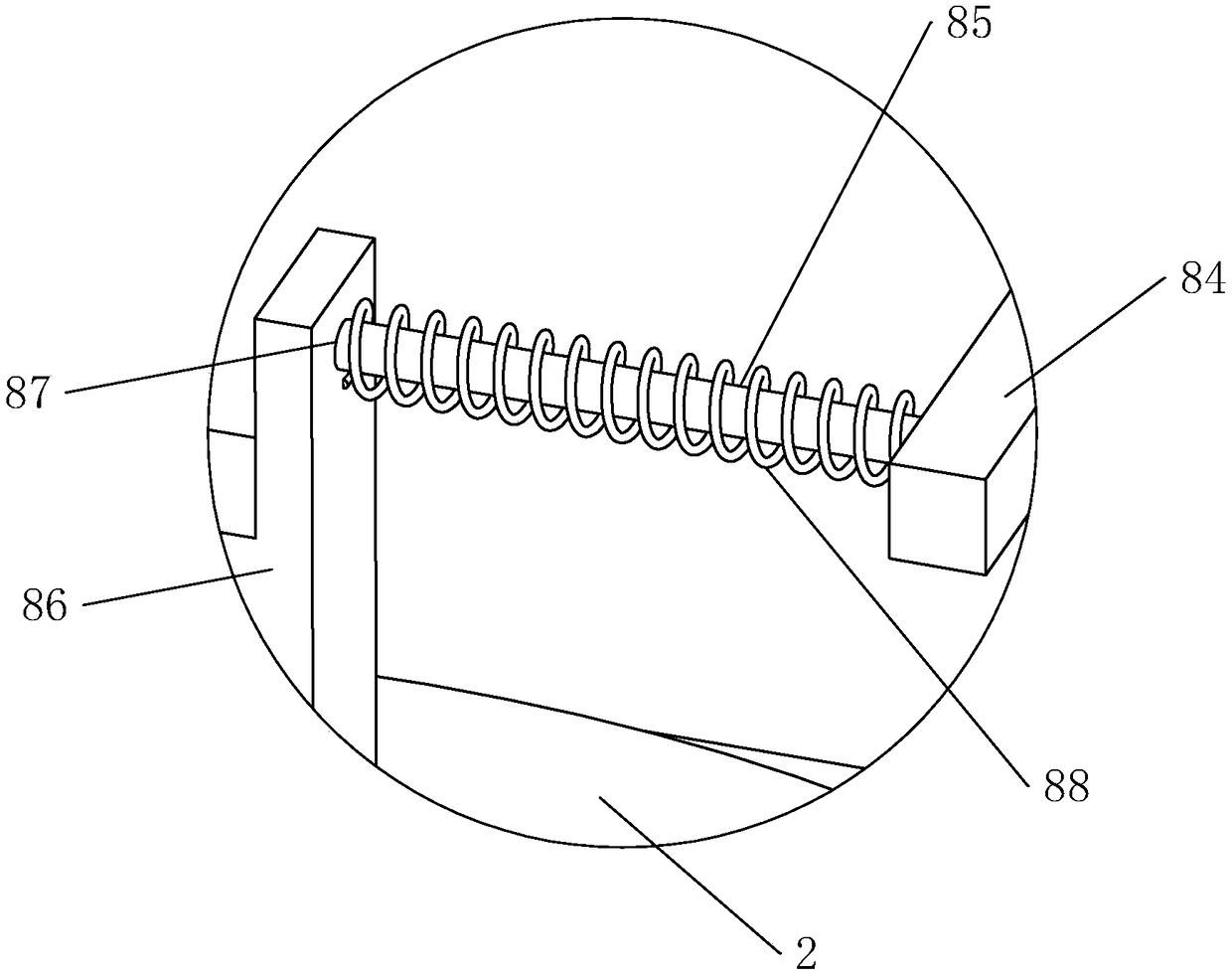

[0036] Such as figure 1As shown, a steel bar bending machine includes a workbench 1, a turntable 2 driven by a main motor inside the workbench 1 is provided on the surface of the workbench 1, a bending hole is eccentrically opened on the turntable 2, and a bending hole is inserted in the bending hole The movable bending pin 22 is provided with a positioning pin 23 at the center of the turntable 2, and a positioning block 3 is fixed on the workbench 1. The bottom surface of the positioning block 3 is located on the upper surface of the turntable 2. The surface of 23 forms a fixed opening for placing and fixing the steel bar 11 to be processed, and the movable bending pin 22 is located on the side of the steel bar 11 facing away from the positioning pin 23 .

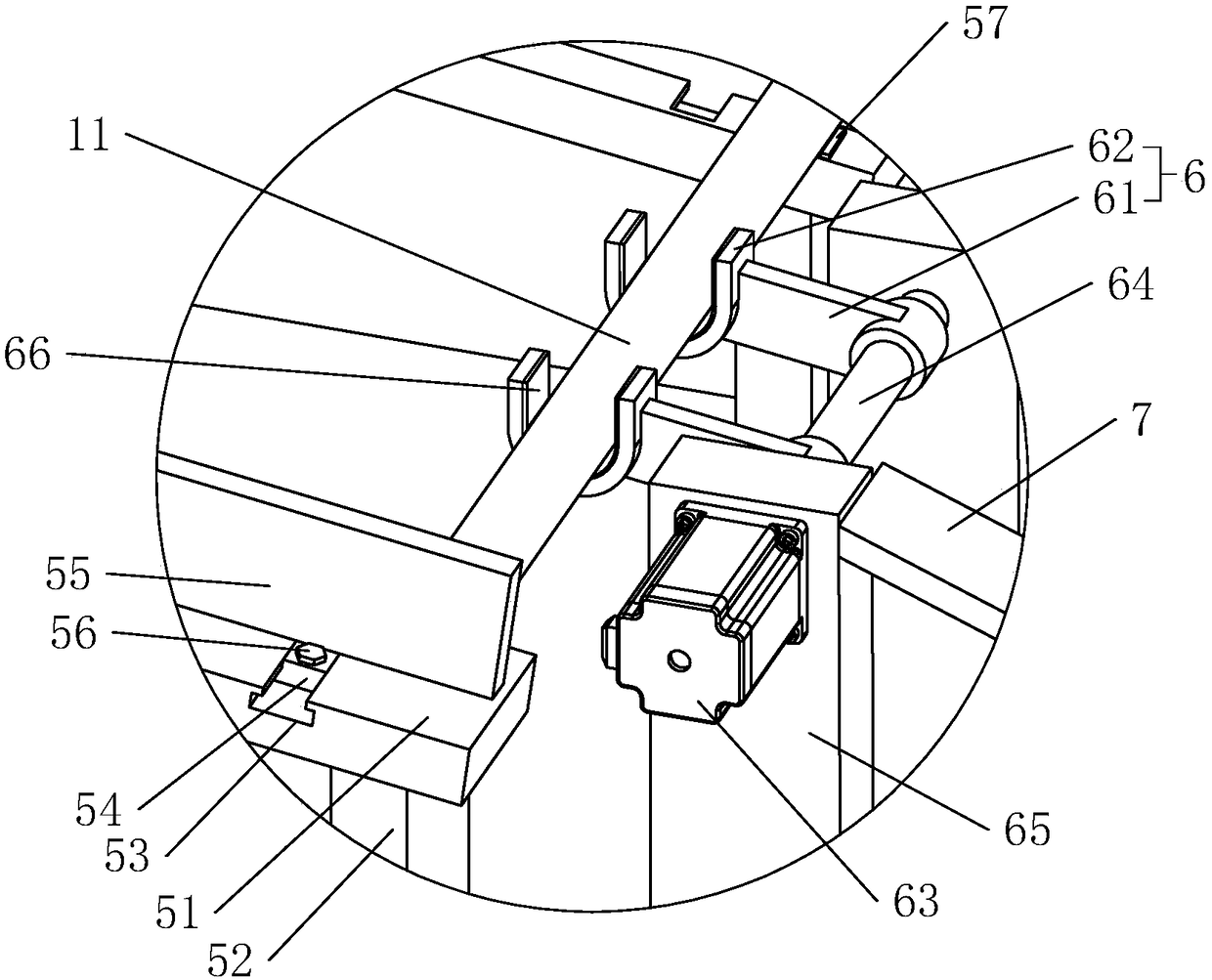

[0037] Such as figure 1 As shown, a feeding device is provided on the workbench 1, and the feeding device includes a storage rack 5, a feeding arm 6, a feeding motor 63 and a feeding slide rail 7 that are distributed in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com