Accurate feeding continuous-flow reaction system capable of quenching

A reaction system and feeding technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the difficulty of installing and replacing catalysts in continuous flow tubular reactors, the difficulty of cleaning continuous flow tubular reactors, and the inability to precisely control the reaction. To solve problems such as objects, to achieve the effect of quick and thorough cleaning, preventing leakage and improving turbulent flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

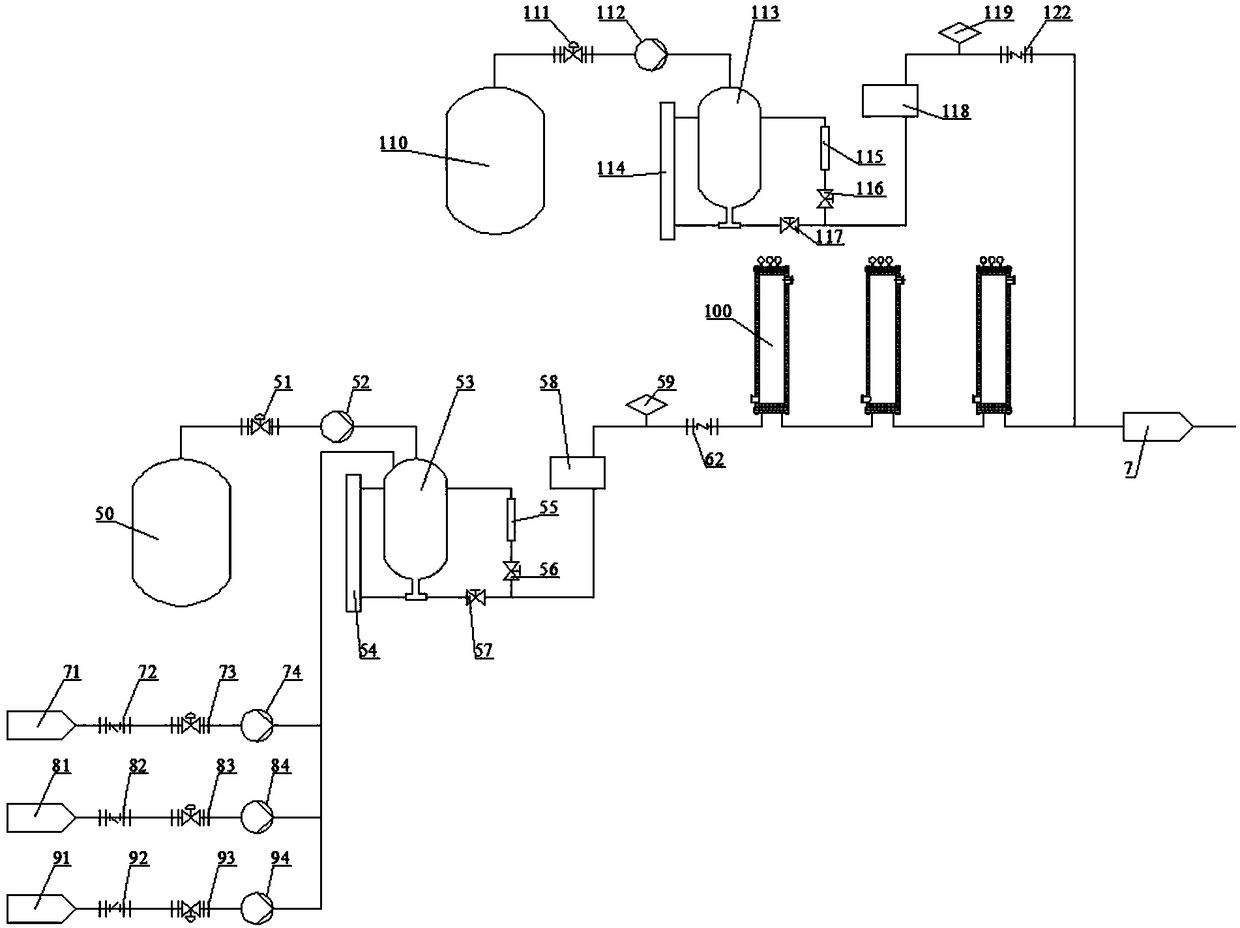

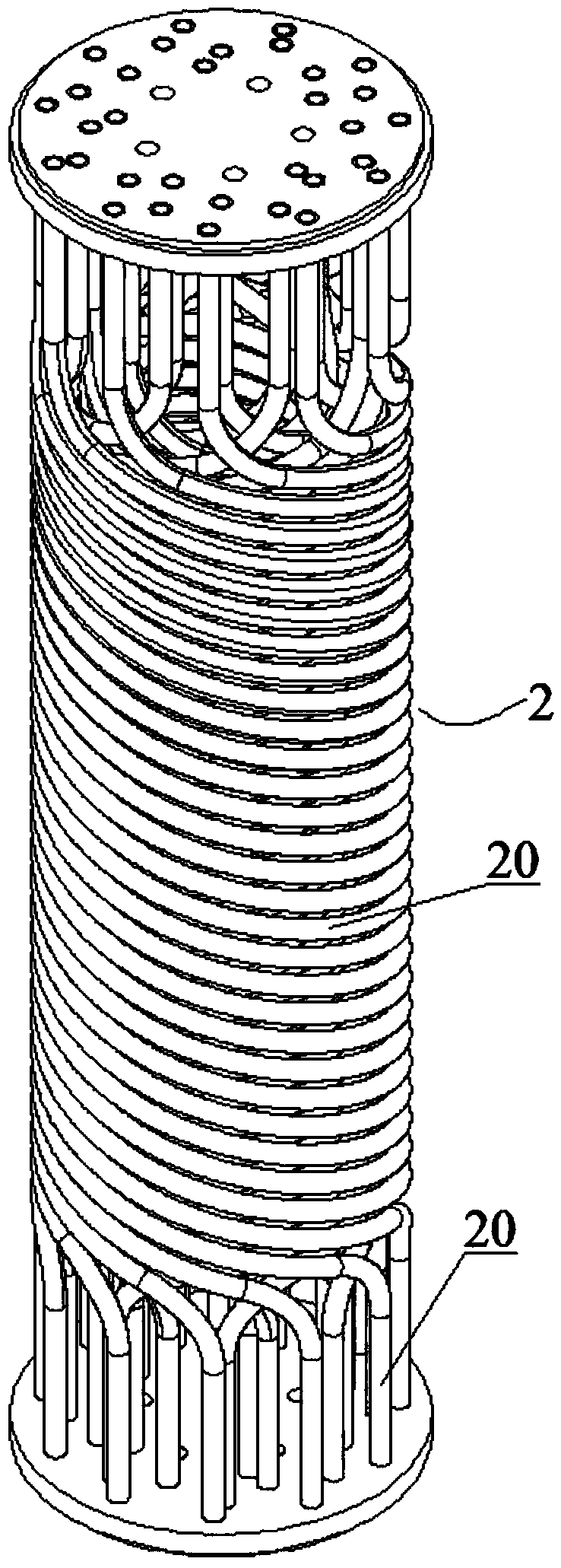

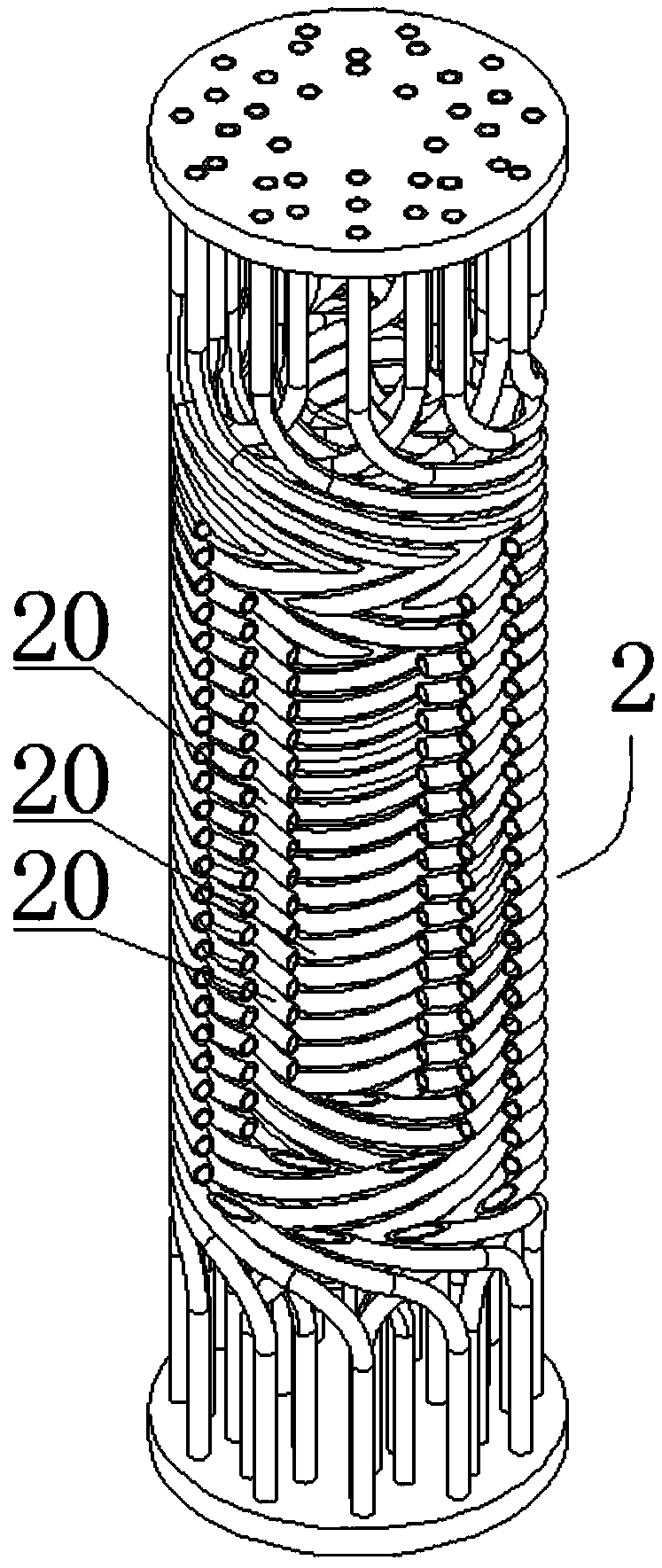

[0039] Such as Figure 1 to Figure 15 As shown, a precise feed continuous flow reaction system that can be quenched in this embodiment is characterized in that it includes: a feed unit, a quench unit, a CIP cleaning unit and a reaction unit 100, and the reaction unit 100 includes A shell 1, the upper and lower ends of the shell 1 are respectively connected with a tube plate 3 and a baffle tube box 4 in sequence,

[0040] The housing 1 is provided with a reaction tube group 2, the reaction tube group 2 includes a plurality of reaction tubes 20, the reaction tubes 20 are helically wound tubes with a certain helix angle, and the upper and lower ends of each reaction tube 20 are Through and fixedly connected to the tube plate 3, several separate baffle grooves 40 are provided on the baffle tube box 4, and the tube plate 3 and the baffle grooves 40 of the baffle tube box 4 jointly form several Phase-separated baffle channels, the adjacent reaction tubes 20 in the flow sequence of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com