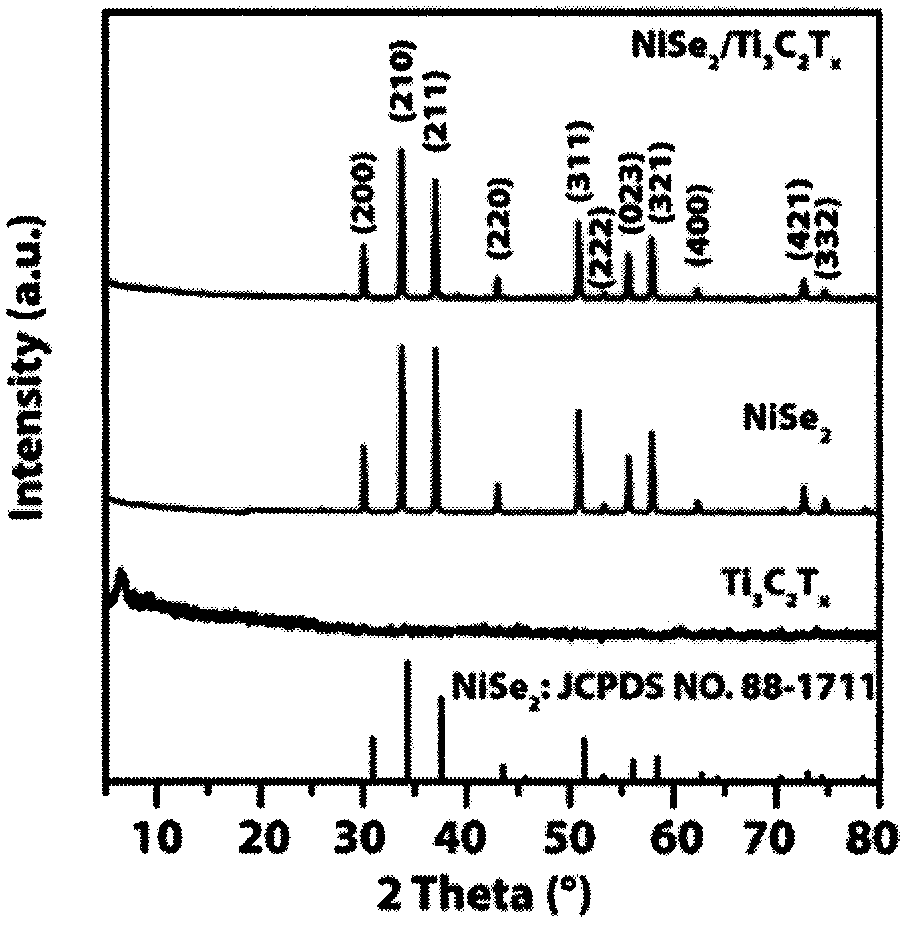

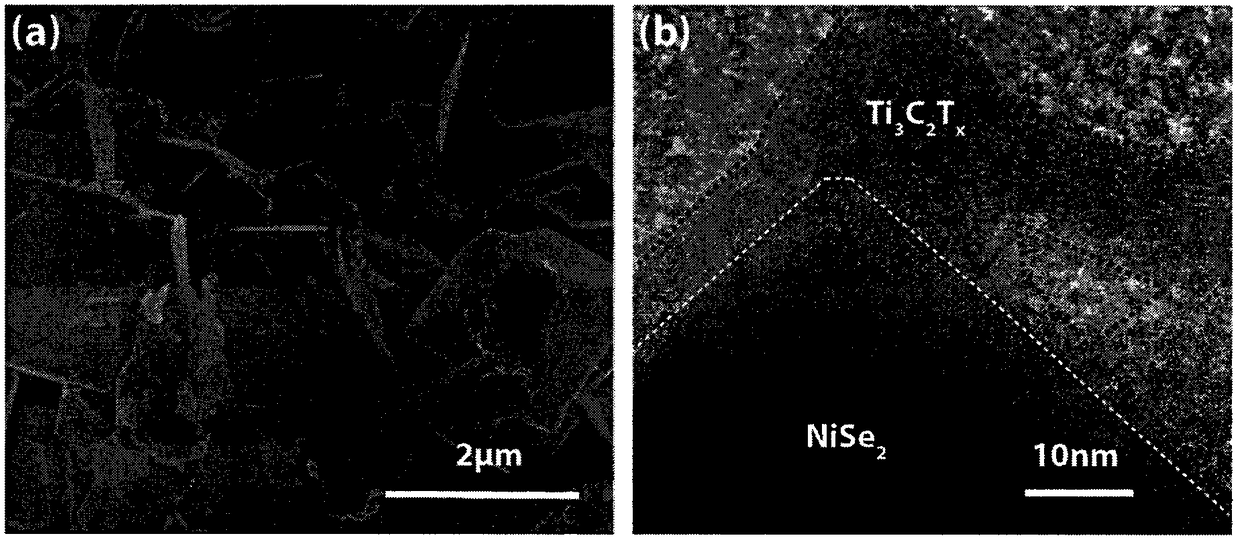

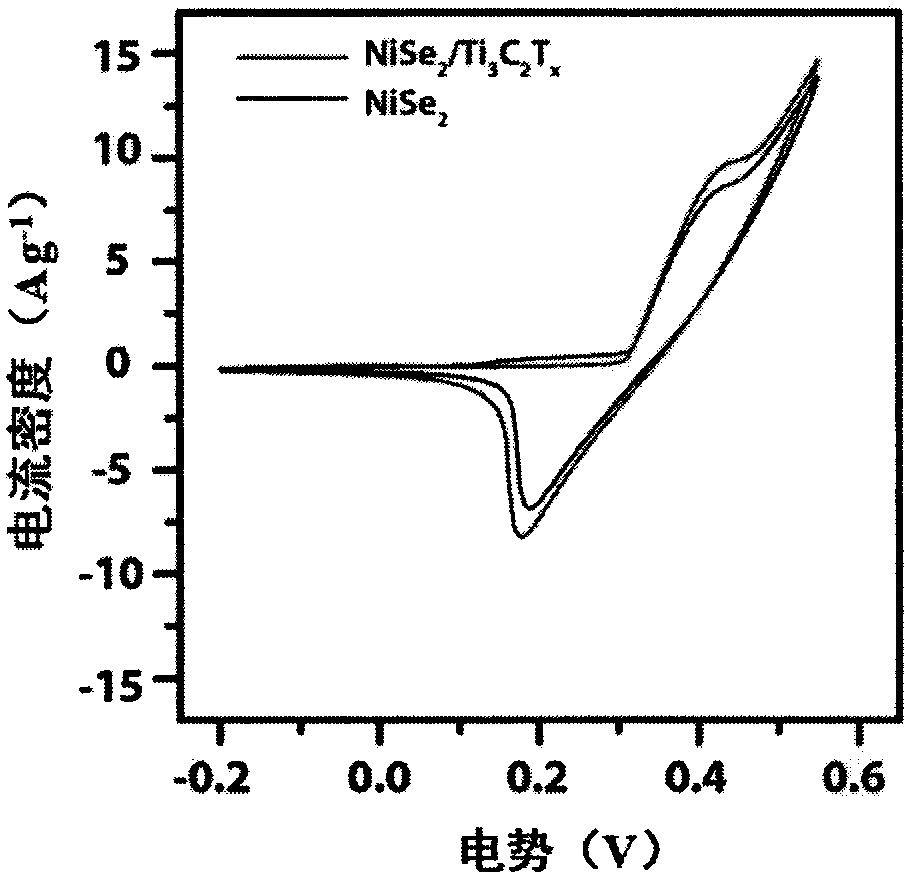

preparation method of NiSe2/Ti3C2Tx high-performance supercapacitor nanocomposite

A technology of nanocomposite materials and supercapacitors, which is applied in the field of preparation of supercapacitor electrode materials, can solve the problems of limited energy density and durability, poor conductivity, etc., and achieve the effects of short process time, high energy density and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1)Ti 3 C 2 T x Preparation of nanosheets:

[0030] 1.1) Add 2g LiF to 20ml HCl and stir until clear.

[0031] 1.2) Add 2g of Ti 3 AlC 2 The powder was added to the solution in step 1.1), the solution was heated at 40° C., and kept at a constant temperature for 48 hours. The reacted solution was washed with deionized water several times and centrifuged until the pH of the supernatant was about 6.

[0032] 1.3) The centrifuged solid in step 1.2) was vacuum-dried at 60°C for 12 hours to obtain Ti 3 C 2 Tx powder.

[0033] 1.4) Weigh the Ti obtained in step 1.3) 3 C 2 Add 100mg of Tx powder to 10ml of water, and ultrasonicate the solution to obtain 10mg·mL -1 Ti 3 C2 T x flake solution.

[0034] 2) NiSe 2 / Ti 3 C 2 T x Preparation of nanocomposites:

[0035] 2.1) 2mmol Se powder was dissolved in 5ml KOH solution to form a maroon solution.

[0036] 2.2) 1 mmol NiCl 2 Dissolve in 19 mL of deionized water, and then add 1.6 mmol of chelating agent such as L ...

Embodiment 2

[0042] Remove step 2) NiSe 2 / Ti 3 C 2 T x The preparation of nanocomposite material, other conditions are with embodiment 1, obtain NiSe 2 , made into a supercapacitor for electrochemical performance measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com