Coal and rock mass multi-field coupling integrated testing device based on drilling bit method

A test device, coal and rock mass technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problems of little guiding significance and inability to monitor multiple parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

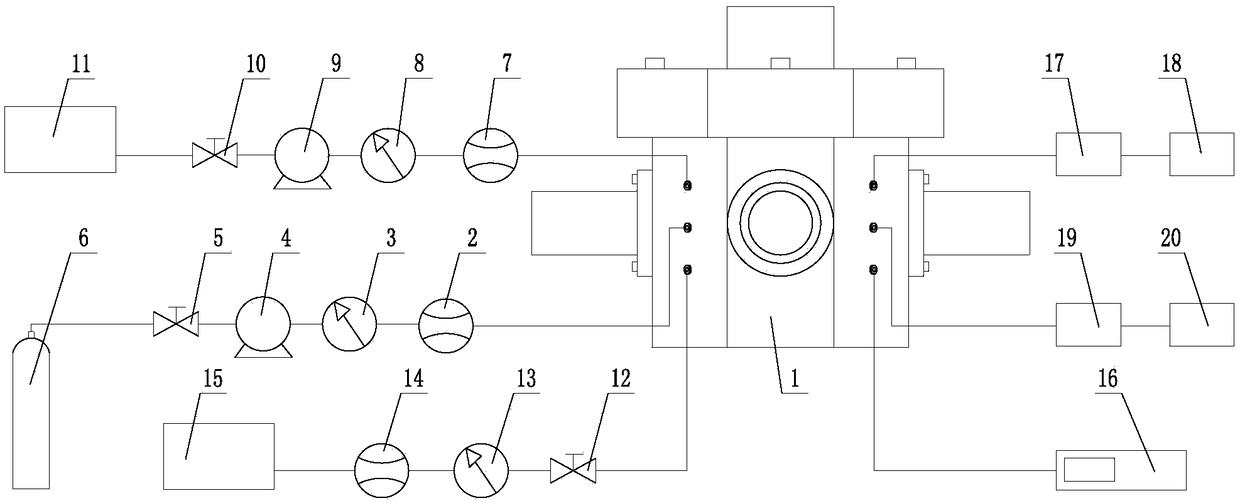

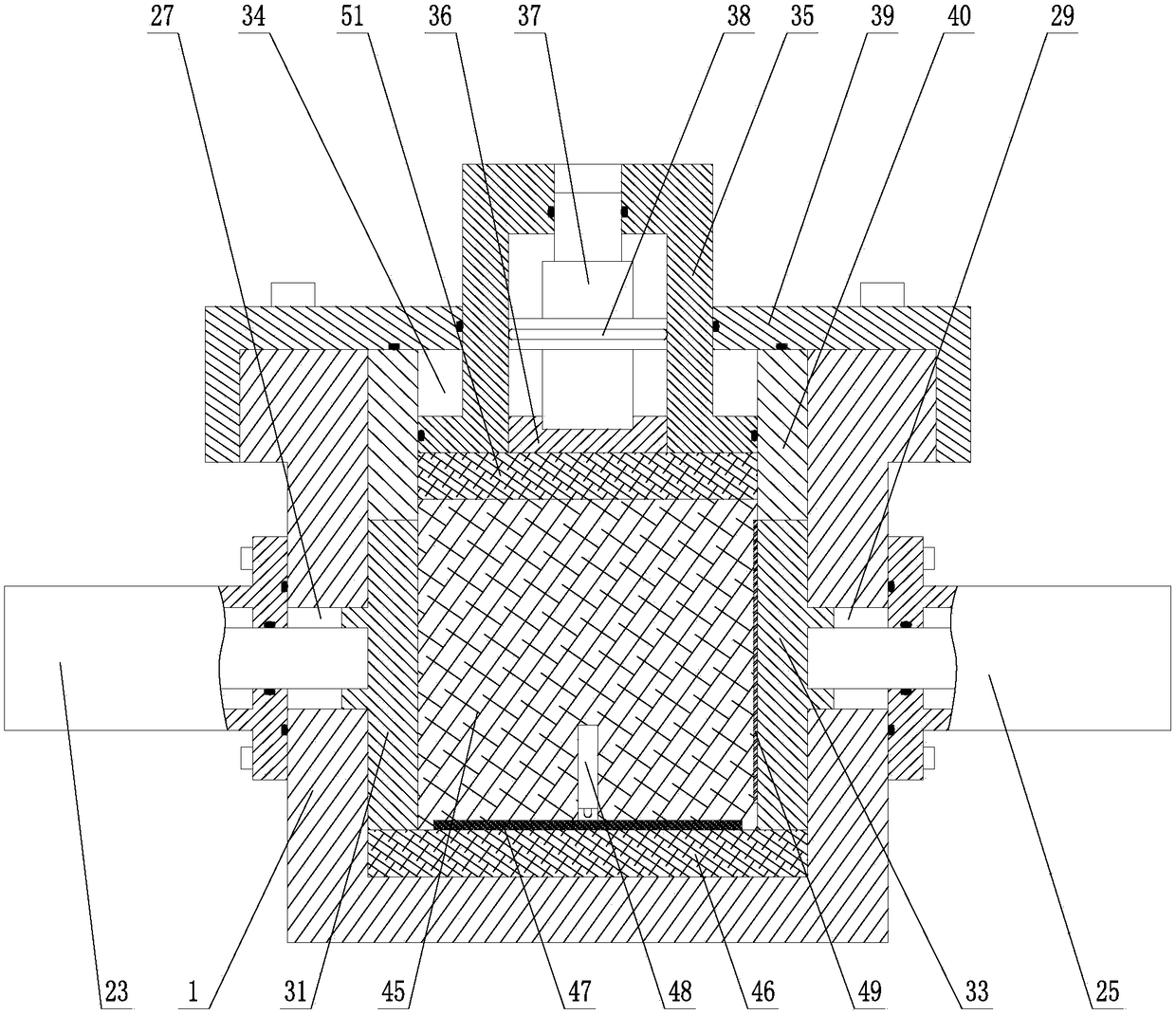

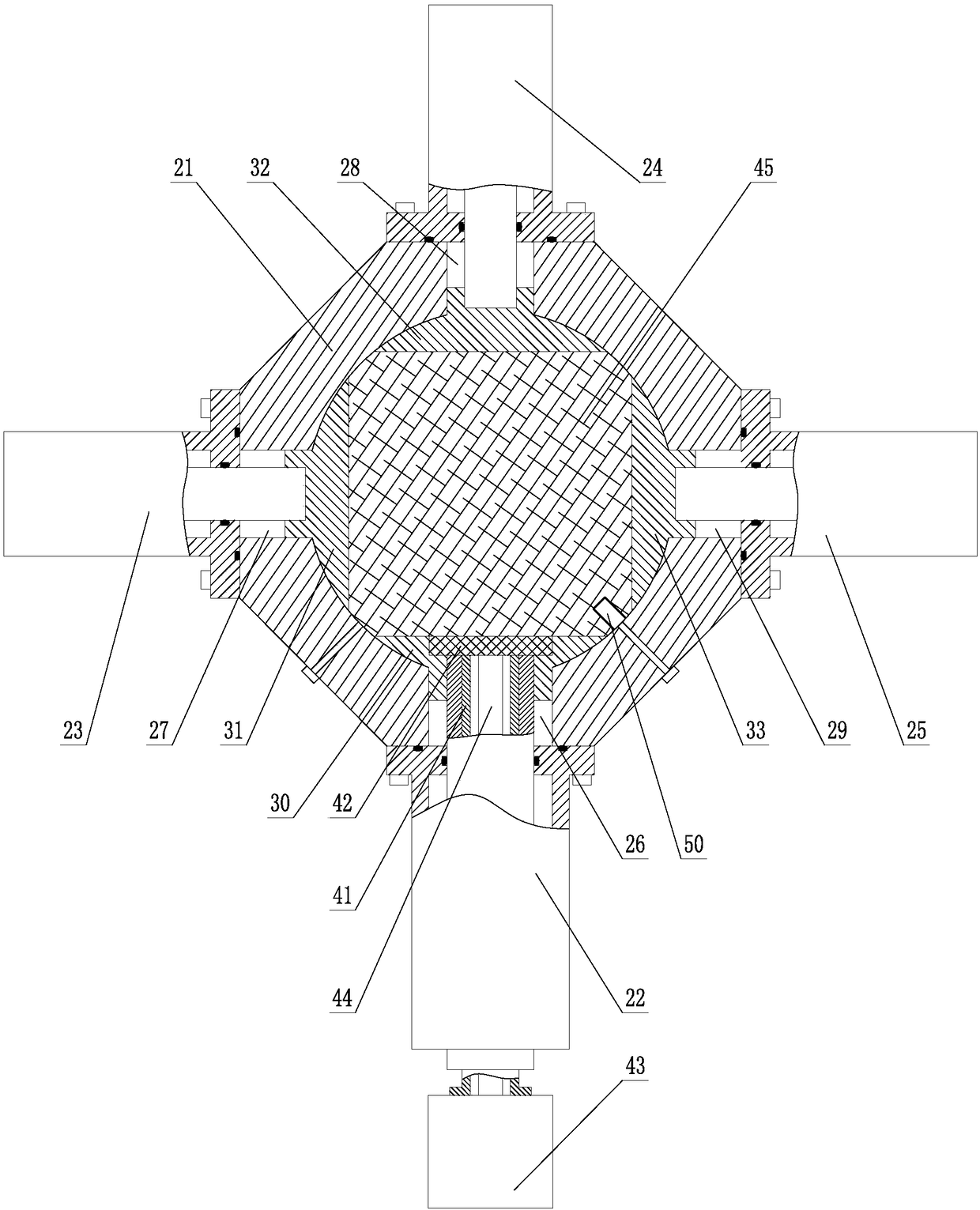

[0017] Such as Figure 1~3 As shown, a coal-rock mass multi-field coupling integrated test device based on the drilling cuttings method includes a true triaxial loading mechanism 1, on which a gaseous fluid loading channel, a liquid fluid loading channel, a Exhaust gas / wastewater discharge channel, temperature signal acquisition channel, charge signal acquisition channel and acoustic emission signal acquisition channel; the outer end interface of the gaseous fluid loading channel is sequentially connected with the first flow meter 2, the first pressure gauge 3, the first stable pressure device 4, a first valve 5 and a gas cylinder 6; the outer end interface of the liquid fluid loading channel is sequentially connected with a second flow meter 7, a second pressure gauge 8, a second pressure regulator 9, a second valve 10 and Water tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com