Mashing device for processing pesticide residue detecting sample

A pesticide residue detection and sample technology, which is applied in the field of pesticide detection, can solve problems such as consumer disease, influence detection results, and pesticide residues exceeding the standard, and achieve the effects of reducing inaccurate detection results, improving detection accuracy, and facilitating extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

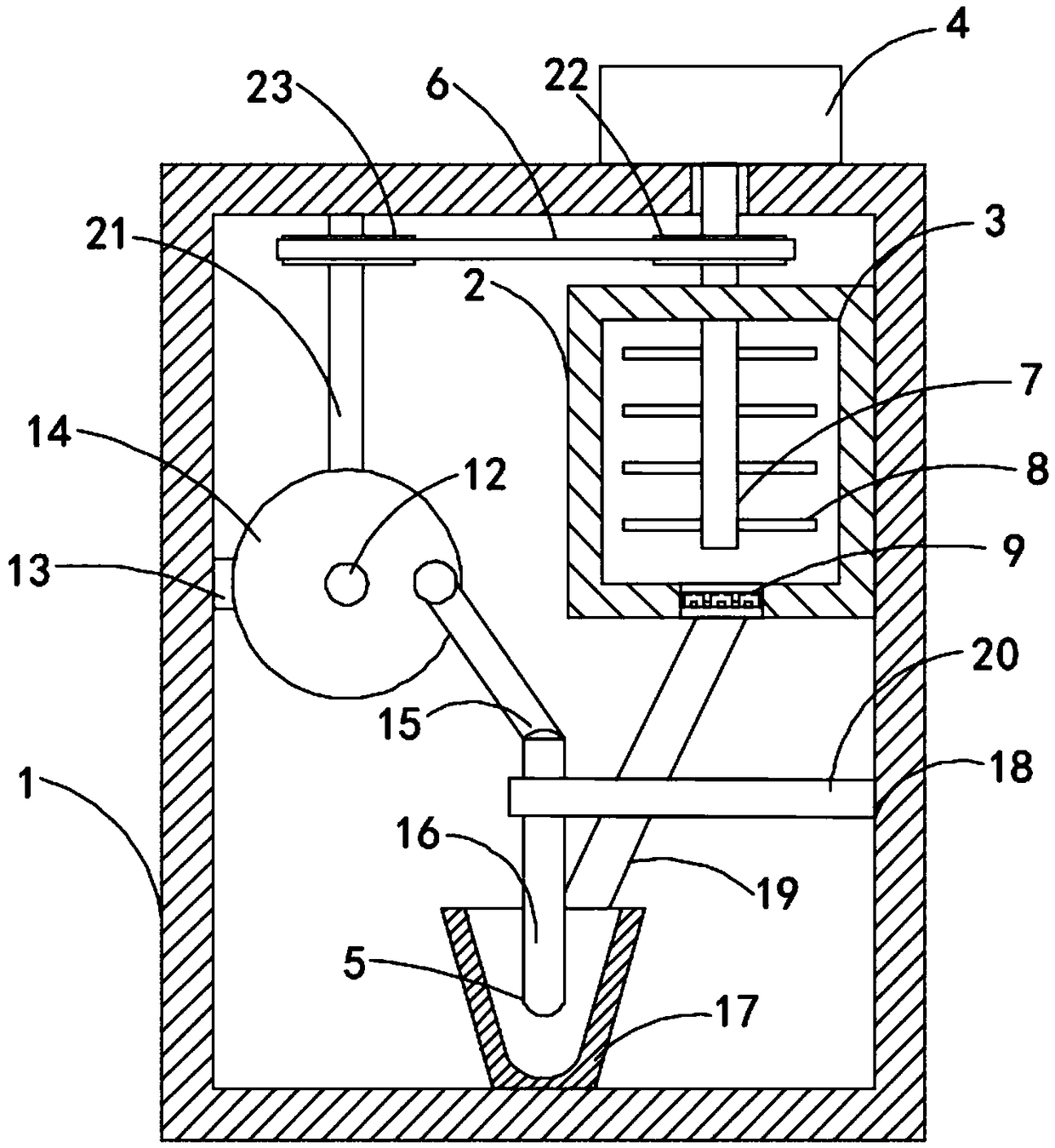

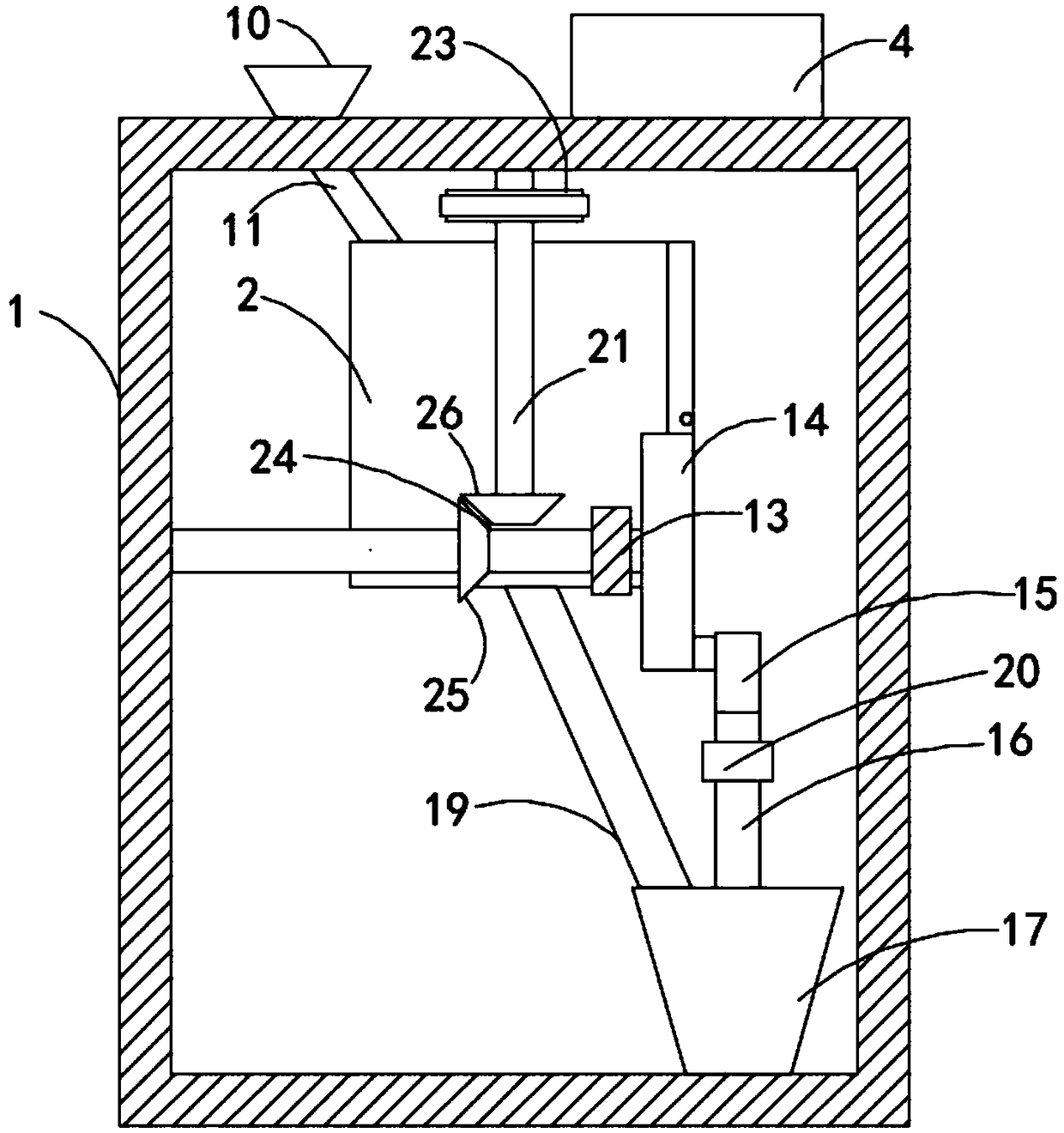

[0022] refer to Figure 1-3 , a crushing device for processing pesticide residue detection samples, including a housing 1. It should be noted that a side door is opened outside the housing 1, and a processing box 2 is fixedly connected inside the housing 1. It is worth mentioning that, The outside of the processing box 2 has a side door, which is convenient for cleaning the inside of the processing box 2. The processing box 2 is provided with a rough machining mechanism 3. Specifically, the rough machining mechanism 3 includes a first rotating shaft fixedly connected with the motor 4 drive shaft. Shaft 7, the lower end of the first rotating shaft 7 runs through the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com