Temperature control system and method for CPS-based ring spinning intelligent workshop

A temperature control system, ring spinning technology, applied in heating and ventilation control system, space heating and ventilation control input, control input involving users/components, etc., can solve the problem of low yarn quality and inconspicuous effect , did not achieve the precise control of temperature and other issues, and achieved the effect of accurate control results and reliable system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, further illustrate the present invention.

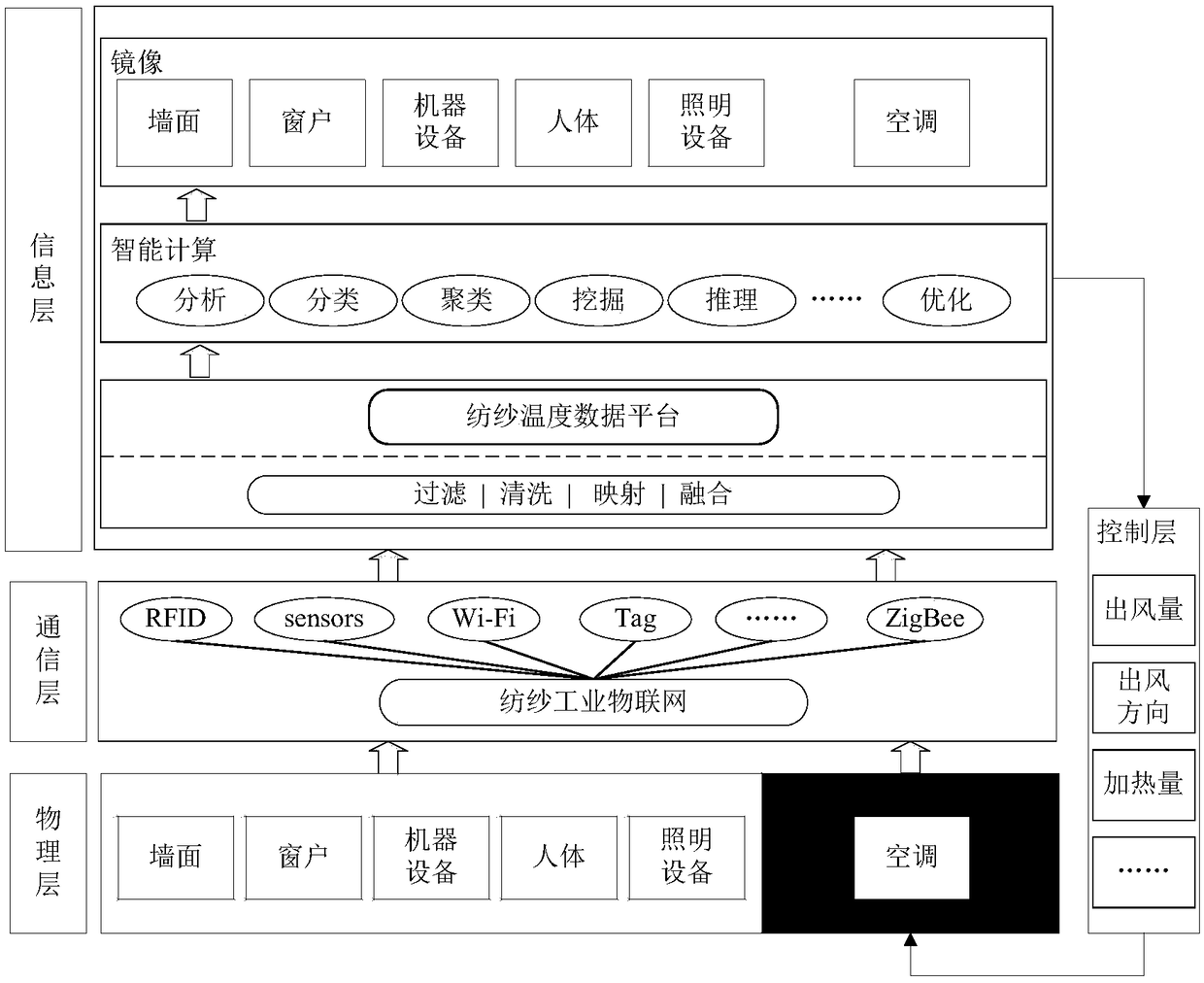

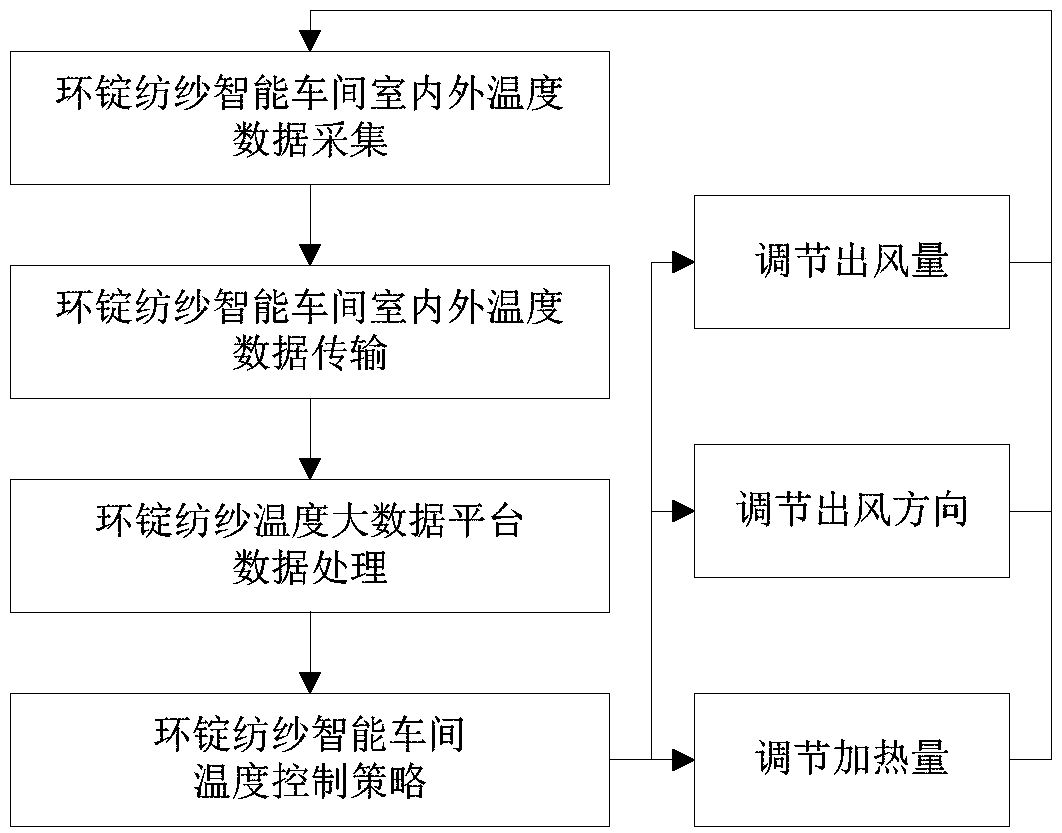

[0028] First of all, based on the concept and characteristics of CPS, combined with the current temperature control status of the enterprise, a closed-loop precise temperature control system architecture for ring spinning intelligent workshop based on CPS is proposed, as shown in figure 1 As shown, the architecture is divided into four layers, namely: physical layer, communication layer, information layer and control layer. Perceive the physical entities related to the spinning temperature, transmit the obtained temperature data to the spinning temperature data platform through the spinning industry Internet, and then intelligently calculate the temperature data, ready-made mirror images of the physical entities, to achieve the accuracy of air volume and air output Direction adjustment to achieve closed-loop precise control of the spinning workshop temperature.

[0029] Physical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com