Well drilling accelerating mechanism

A technology of drilling and drilling tools, which is applied in the field of petroleum geology drilling tools, can solve the problems of no drilling pressure extension ability and the inability to improve the rock-breaking ability of the drill bit, and achieve the goals of overcoming shallow rock-breaking depth, prolonging the effective working time, and high-efficiency drilling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

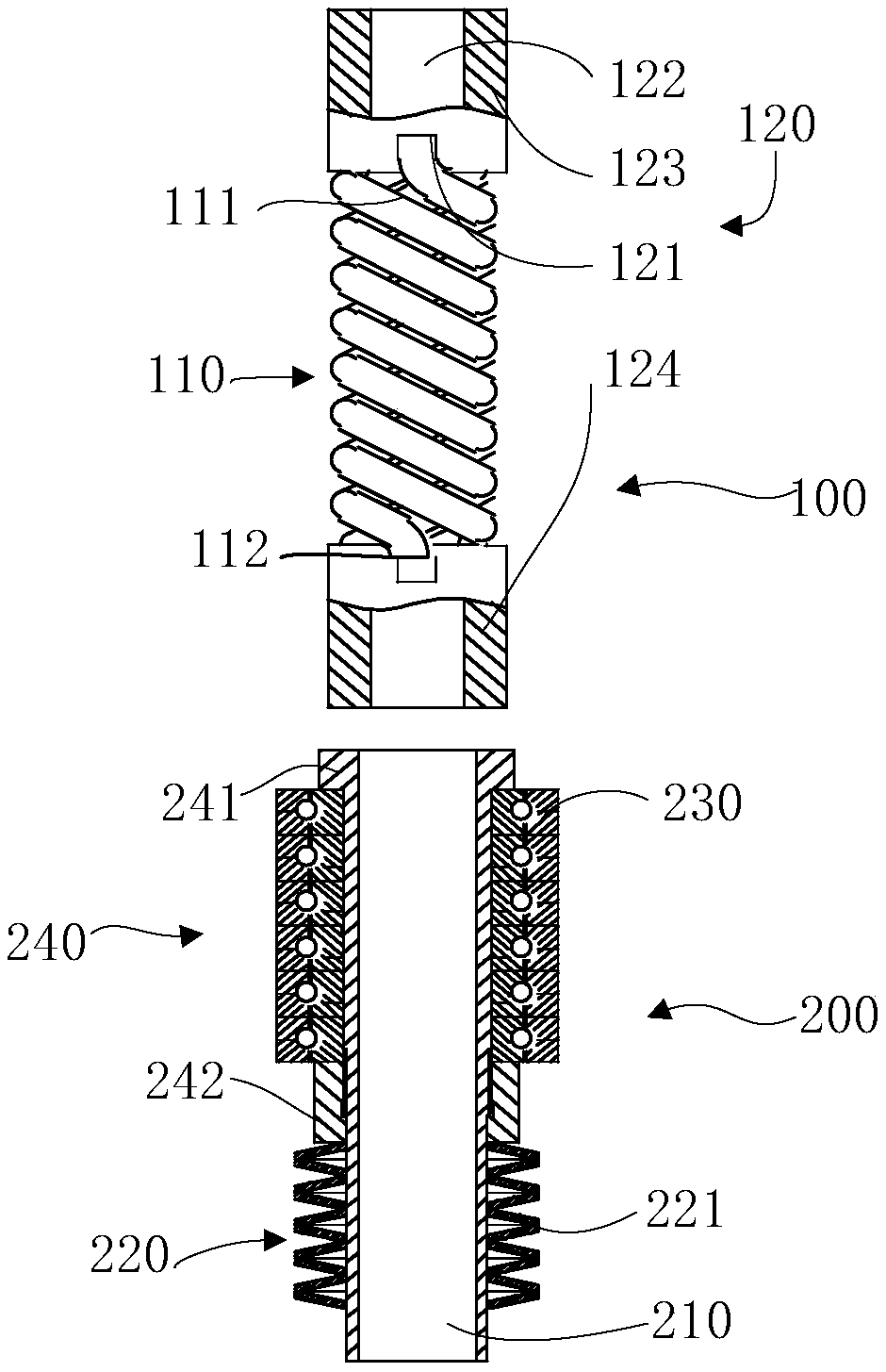

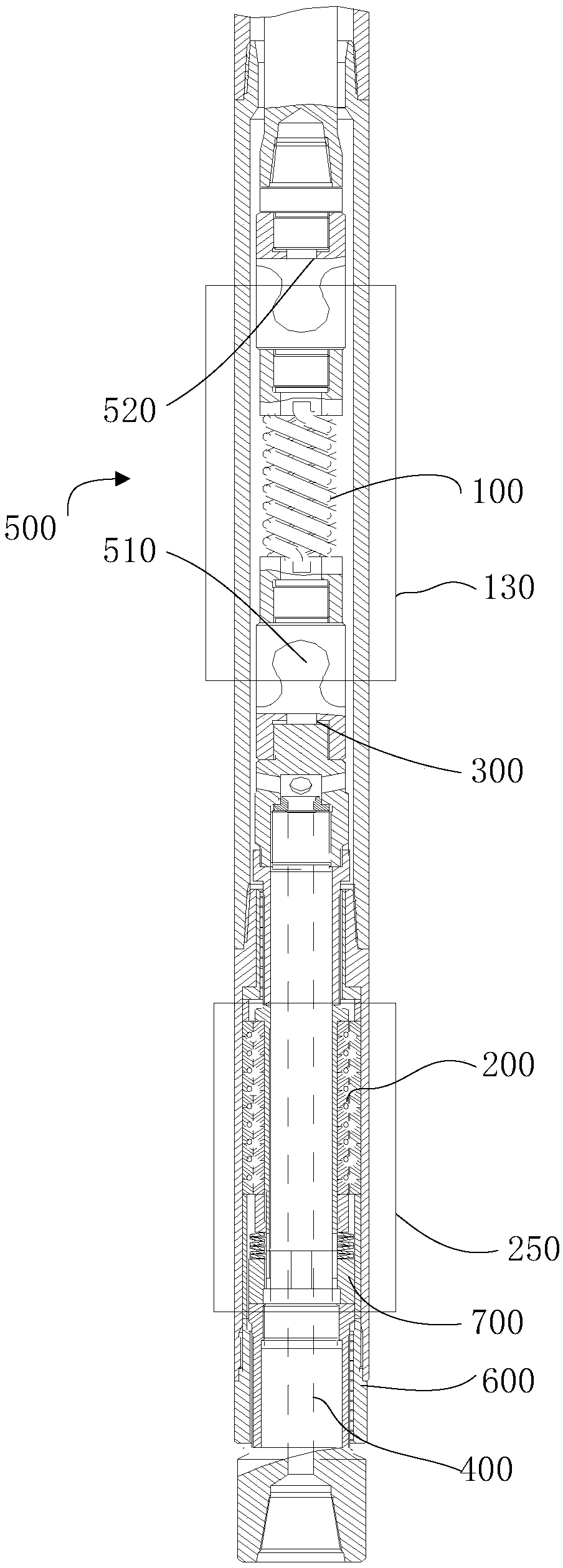

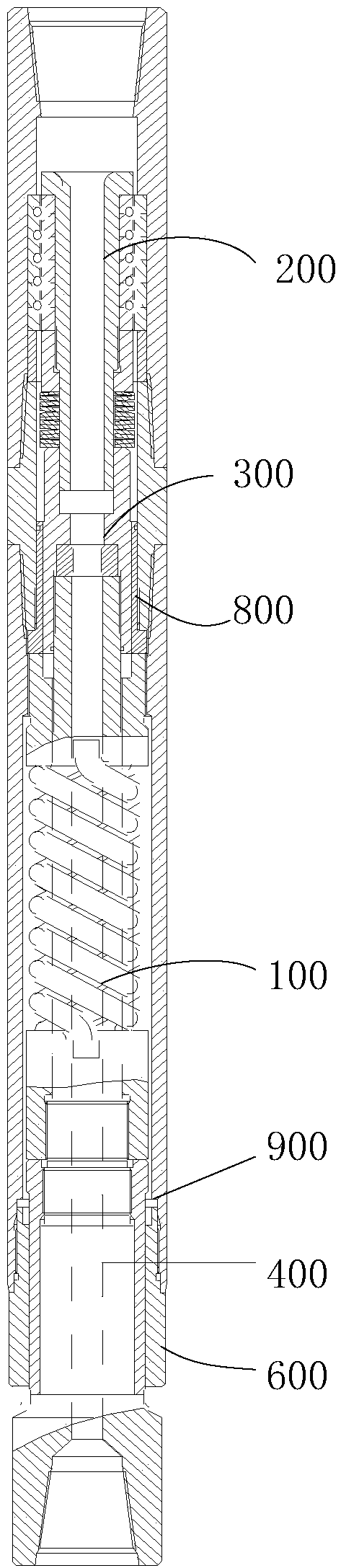

[0051] This embodiment provides a drilling speed-increasing mechanism, which is installed between the output shaft of the drilling tool and the power assembly, please refer to Figure 1 to Figure 3 . figure 1 A cross-sectional view of the drilling acceleration mechanism provided by the embodiment of the present invention; figure 2 It is a schematic diagram of the installation of the drilling speed-up mechanism in the screw drilling tool provided by the embodiment of the present invention; image 3 It is a schematic diagram of the installation of the drilling speed increasing mechanism in the torsional percussion drilling tool provided by the embodiment of the present invention.

[0052] It includes a circumferential buffer accumulator 100, an axial buffer accumulator 200 and a connection assembly 300; the lower end of the circumferential buffer accumulator 100 is connected to the upper end of the axial buffer accumulator 200 through the connection assembly 300; or the axial ...

Embodiment 2

[0086] This embodiment is another preferred solution paralleled with Embodiment 1. The technical solution disclosed in Embodiment 1 outside the distinguishing technical features belongs to the scope disclosed in this embodiment. Embodiment 1 outside the distinguishing technical features The disclosed technical solutions will not be described repeatedly.

[0087] This embodiment provides a screw drilling tool, please refer to Figure 1 to Figure 2 , figure 1 A cross-sectional view of the drilling acceleration mechanism provided by the embodiment of the present invention; figure 2 It is a schematic diagram of the installation of the drilling speed increasing mechanism in the screw drilling tool provided by the embodiment of the present invention.

[0088] Including drilling speed-up mechanism, transmission shaft 400, universal joint 500 and transmission shaft housing 600; axial buffer accumulator 200 is installed in the annular space between transmission shaft housing 600 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com