Wellhead assembly bottom connecting device for shortening surface-drilling working time

A wellhead device and connection device technology, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of increased drilling operation time, complicated cementing operation, low work efficiency, etc. The effect of reducing the difficulty of well operations, improving the efficiency of field operations, and saving cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

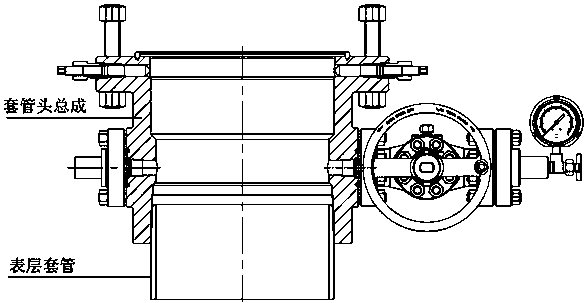

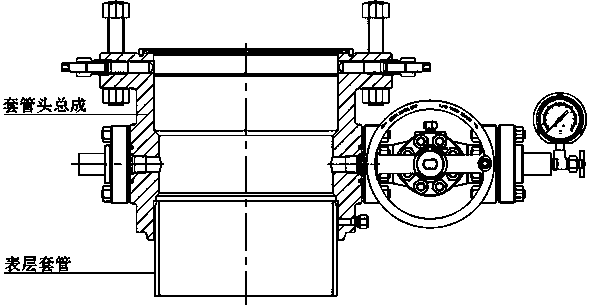

[0029] refer to Figure 4 As shown, a bottom connection device of a wellhead device for shortening the drilling operation time in one opening includes a standard base assembly 1 , a surface casing mandrel hanger 2 , an adapter 3 and a wellhead device assembly 4 . The surface casing mandrel hanger 2 is arranged on and in contact with the upper end face of the standard base assembly 1 , and the surface casing mandrel hanger 2 is screwed with the surface casing 5 . That is, during standard installation, the bottom of the wellhead device assembly 4 is threadedly connected to the surface casing 5 through the surface casing mandrel hanger 2 and the adapter 3 .

[0030] The upper end of the surface casing mandrel hanger 2 is provided with a sealing part 6 whose outer diameter is the same as the outer diameter of the surface casing 5 . During installation, the sealing part 6 extends into the lower inner cavity of the wellhead device assembly 4 and is connected to the wellhead. The in...

Embodiment 2

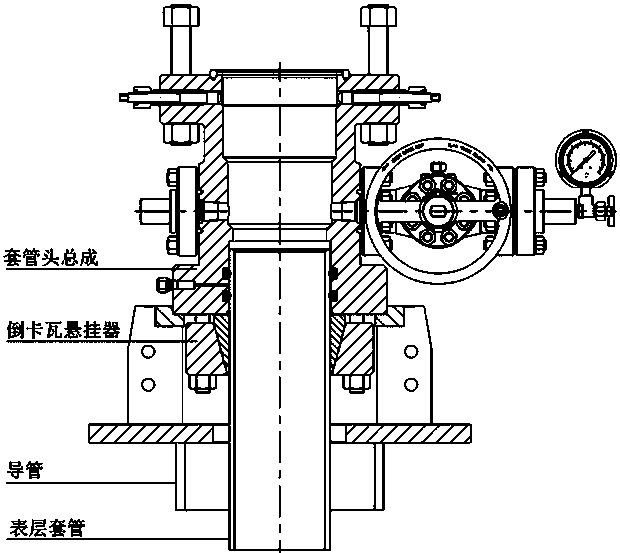

[0036] like Figure 5 As shown, the connection device at the bottom of the wellhead device also includes an emergency base assembly 16 and an emergency inverted slip hanger 17. The wellhead device assembly 4 is located on the upper end face of the emergency base assembly 16; during emergency installation, the bottom of the wellhead device assembly 4 passes through The emergency inverted slip hanger 17 is connected with the surface casing 5 to realize slip connection.

[0037] Among them, the emergency inverted slip hanger 17 includes a slip seat 18 and a slip tooth 19, the slip seat 18 and the slip tooth 19 are detachably connected by the set screw 20 of the side wall, and the lower end of the wellhead assembly 4 is connected by The bolt 12 is detachably connected to the slip seat 18 of the emergency reverse slip hanger 17 , and the inner wall of the lower cavity of the wellhead device assembly 4 is sealedly connected to the surface casing 5 through the sealing device 21 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com