Tuning Liquid Inertial Systems

A liquid type and liquid container technology, which is applied in the field of energy consumption and vibration reduction of civil engineering structures, can solve the problems of single energy consumption mechanism of tuning liquid, increase the difficulty of installation of the device, and occupy a large space for the device, and achieve strong robustness and energy saving. Installation space, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

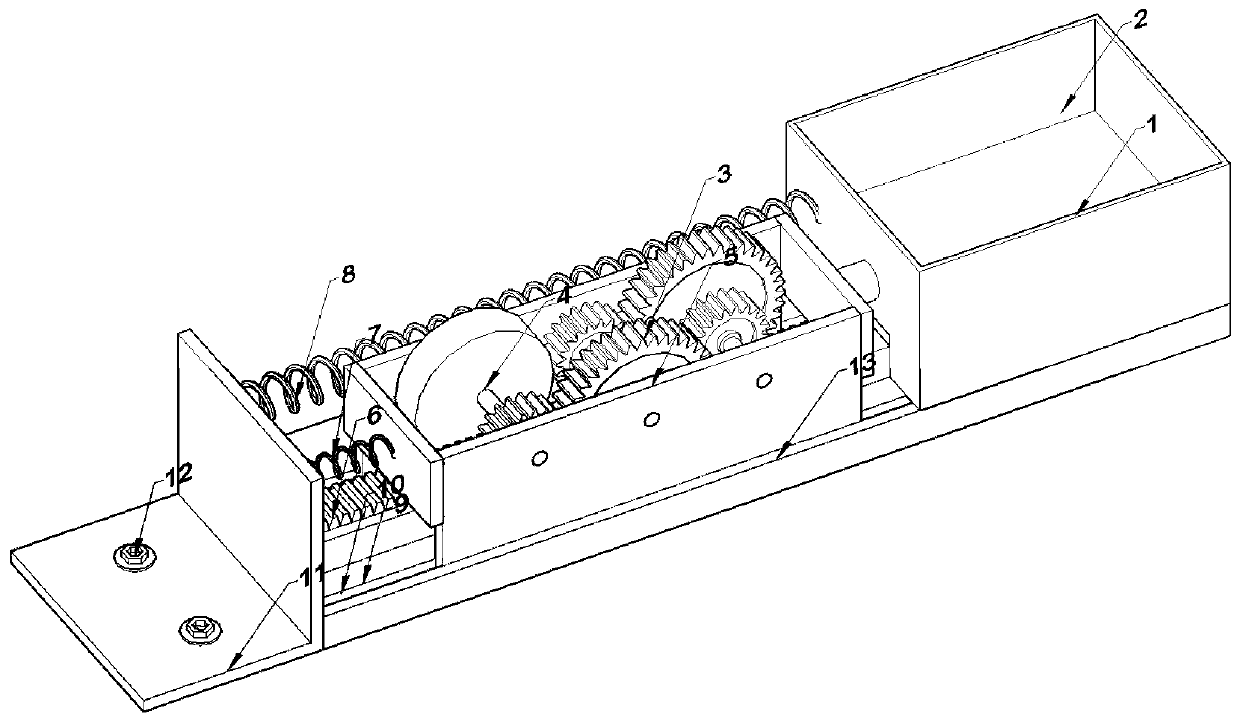

[0022] Such as figure 1 As shown, a tuned liquid type inertial capacity system includes a tuned liquid mass unit, a tuned spring 8, a tuned inertial capacity limiting unit and an installation unit.

[0023] The installation unit includes an integrally formed installation base 13 and an "L"-shaped connection plate 11, the left side of the vertical part of the connection plate 11 is its horizontal part, and the right side is the installation base 13; The sliding groove 9 of the vertical part of the plate 11, the friction plate 10 is housed in the sliding groove 9.

[0024] The liquid inertial damping unit includes a gear unit 3 , a bearing 4 , an inertial unit container 5 , a rack 6 and an inertial tuning spring 7 . Wherein, the gear set unit 3 is placed in the inertial unit container 5, and is connected with the front and rear inner walls of the inertial unit container 5 through the bearing 4; the upper left side of the inertial unit container 5 is connected to the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com