Intelligent efficient space-saving and environment-friendly dry production line for synthetic leather

A synthetic leather and space-saving technology, applied in textiles and papermaking, etc., can solve the problem that the length of the oven cannot meet the requirements, and achieve the effects of maintaining a healthy environment, saving space, and speeding up the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

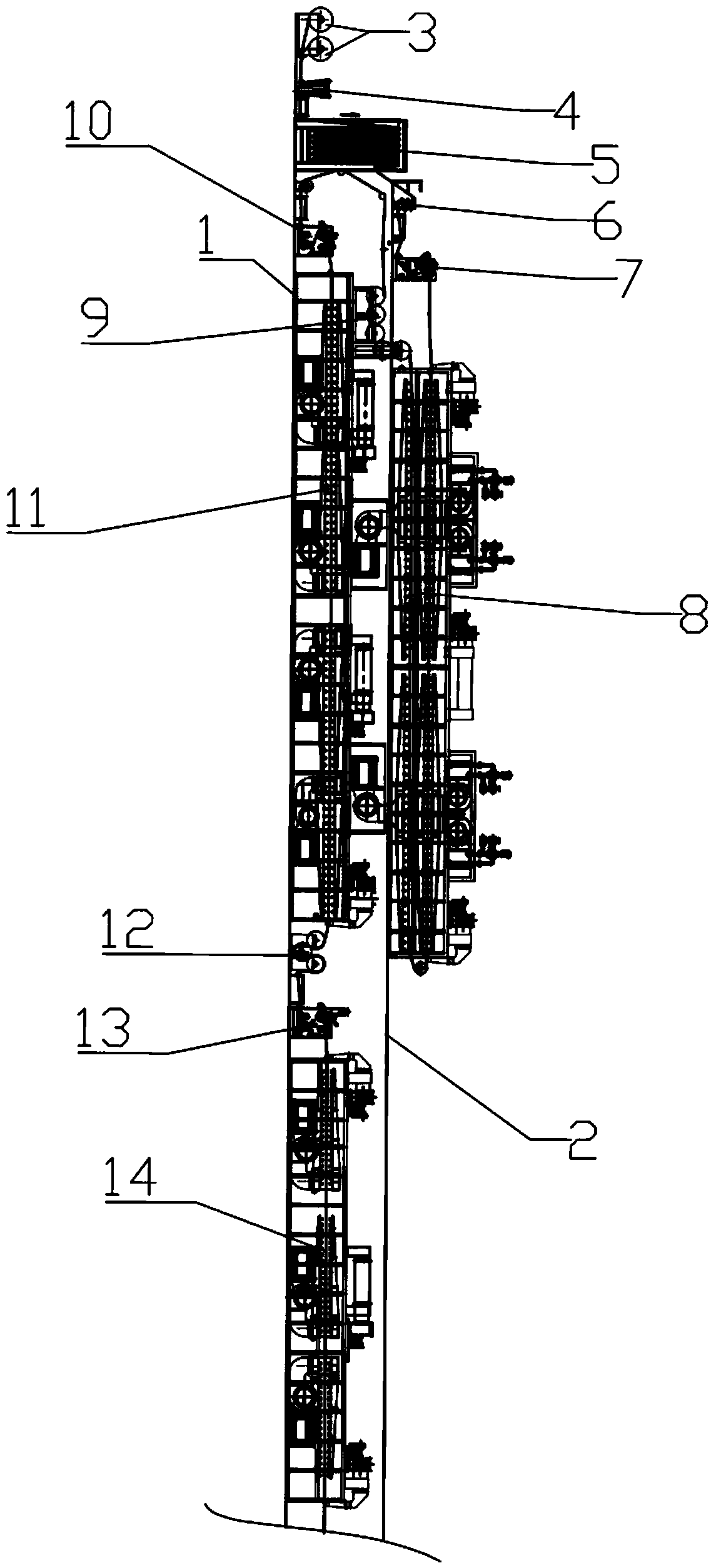

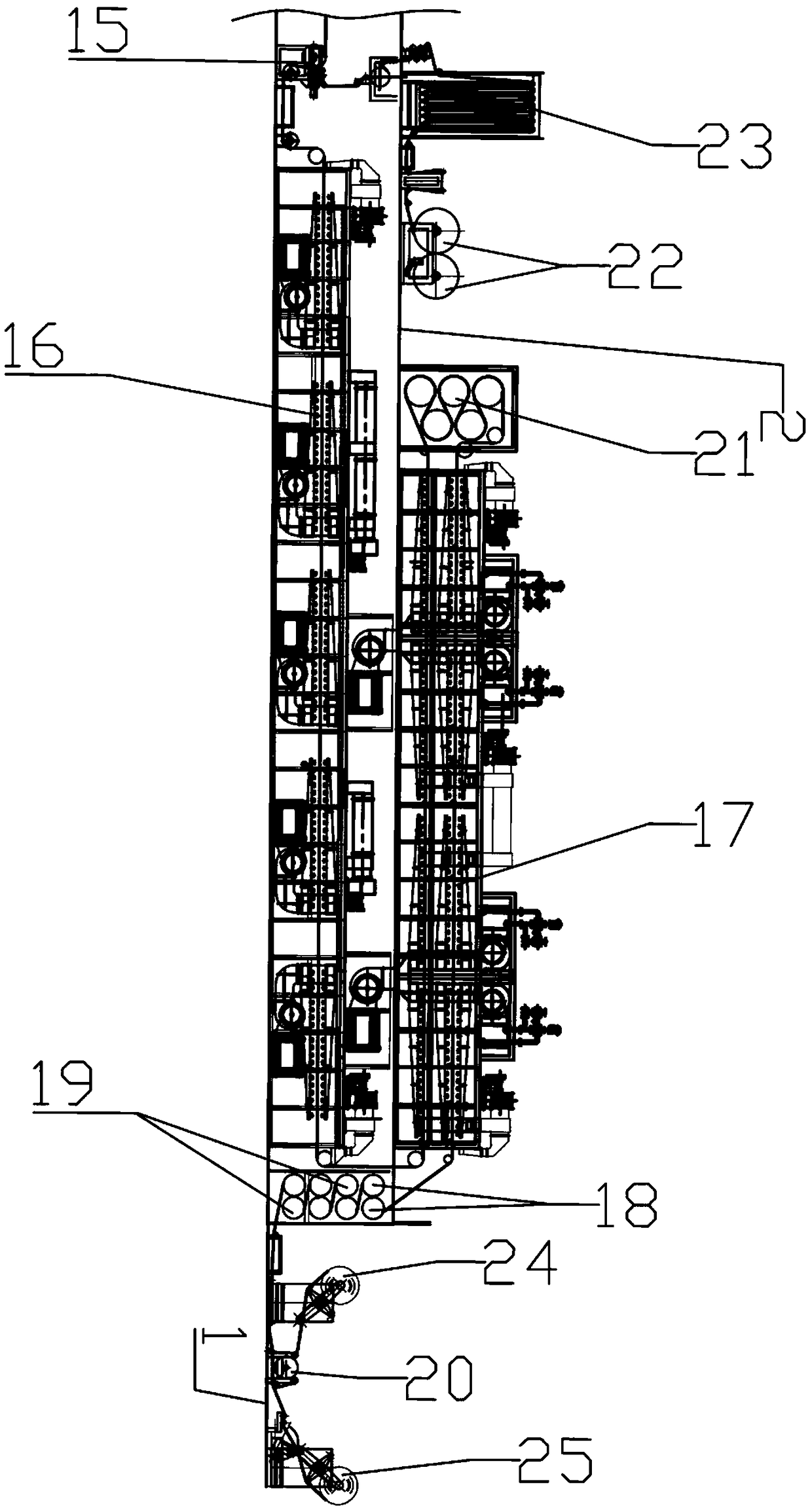

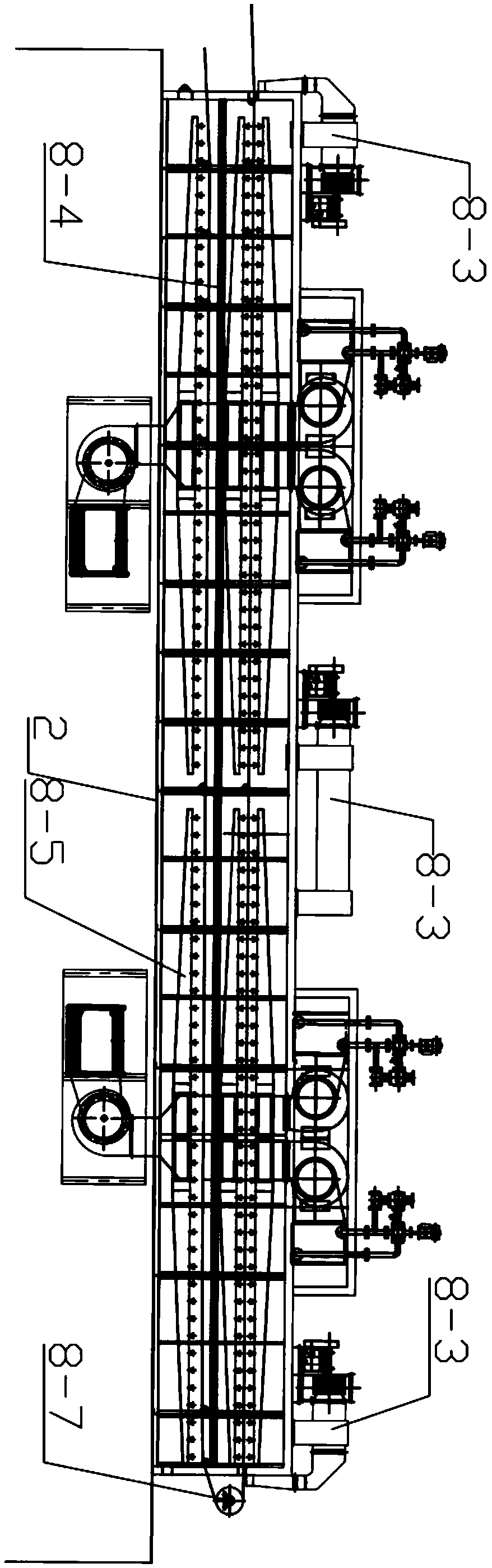

[0041] Such as Figures 1 to 10 Shown, a kind of synthetic leather is used the intelligent high-efficiency space-saving environmental protection dry process production line, comprises the first equipment platform 1 and the second equipment platform 2; The described first equipment platform 1 is positioned at the bottom of the described second equipment platform 2; The leather processing steps include the release paper unwinding machine 3, the paper receiving table 4, the paper storage machine 5, the tensioner 6, the first coating machine 7, and the upper drying chamber 8-1 of the first double-layer oven 8 arranged in sequence. , the lower drying chamber 8-2 of the first double-layer oven 8, five-wheel cooling roll 9, the second coating machine 10, the first single-layer oven 11, three-wheel cooling roll 12, the third coating machine 13, the second coating machine Two single-layer ovens 14, laminating rollers 15, third single-layer ovens 16, lower drying chambers 8-2 of the sec...

Embodiment 2

[0043] Such as Figures 1 to 10 Shown, a kind of synthetic leather is used the intelligent high-efficiency space-saving environmental protection dry process production line, comprises the first equipment platform 1 and the second equipment platform 2; The described first equipment platform 1 is positioned at the bottom of the described second equipment platform 2; The leather processing steps include the release paper unwinding machine 3, the paper receiving table 4, the paper storage machine 5, the tensioner 6, the first coating machine 7, and the upper drying chamber 8-1 of the first double-layer oven 8 arranged in sequence. , the lower drying chamber 8-2 of the first double-layer oven 8, five-wheel cooling roll 9, the second coating machine 10, the first single-layer oven 11, three-wheel cooling roll 12, the third coating machine 13, the second coating machine Two single-layer ovens 14, laminating rollers 15, third single-layer ovens 16, lower drying chambers 8-2 of the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com