Prestress joint production line for producing concrete slabs and concrete beams

A technology for concrete beams and concrete slabs, which is applied in the production of concrete slabs and concrete beams, can solve problems such as damage, a large number of concrete piles, and high production costs of working platforms, and achieve the effect of increasing strength and reducing buckling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

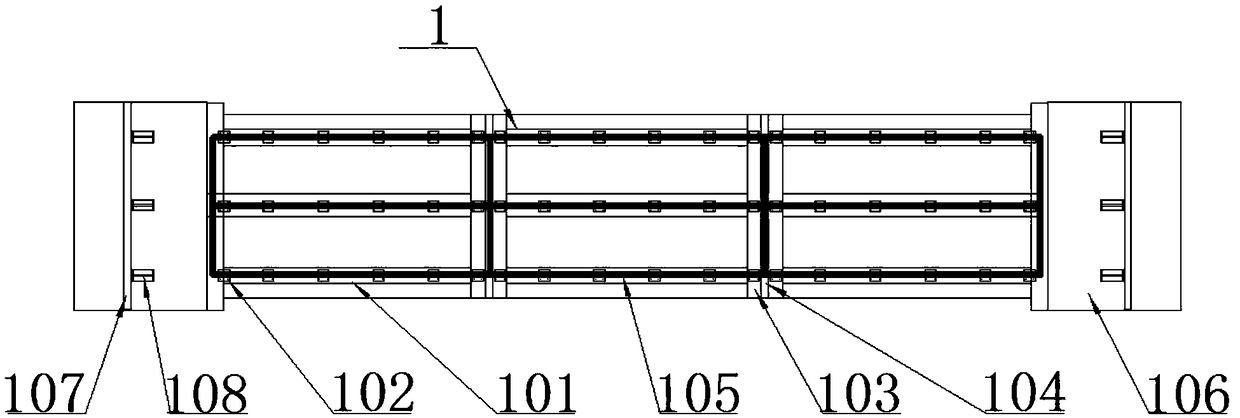

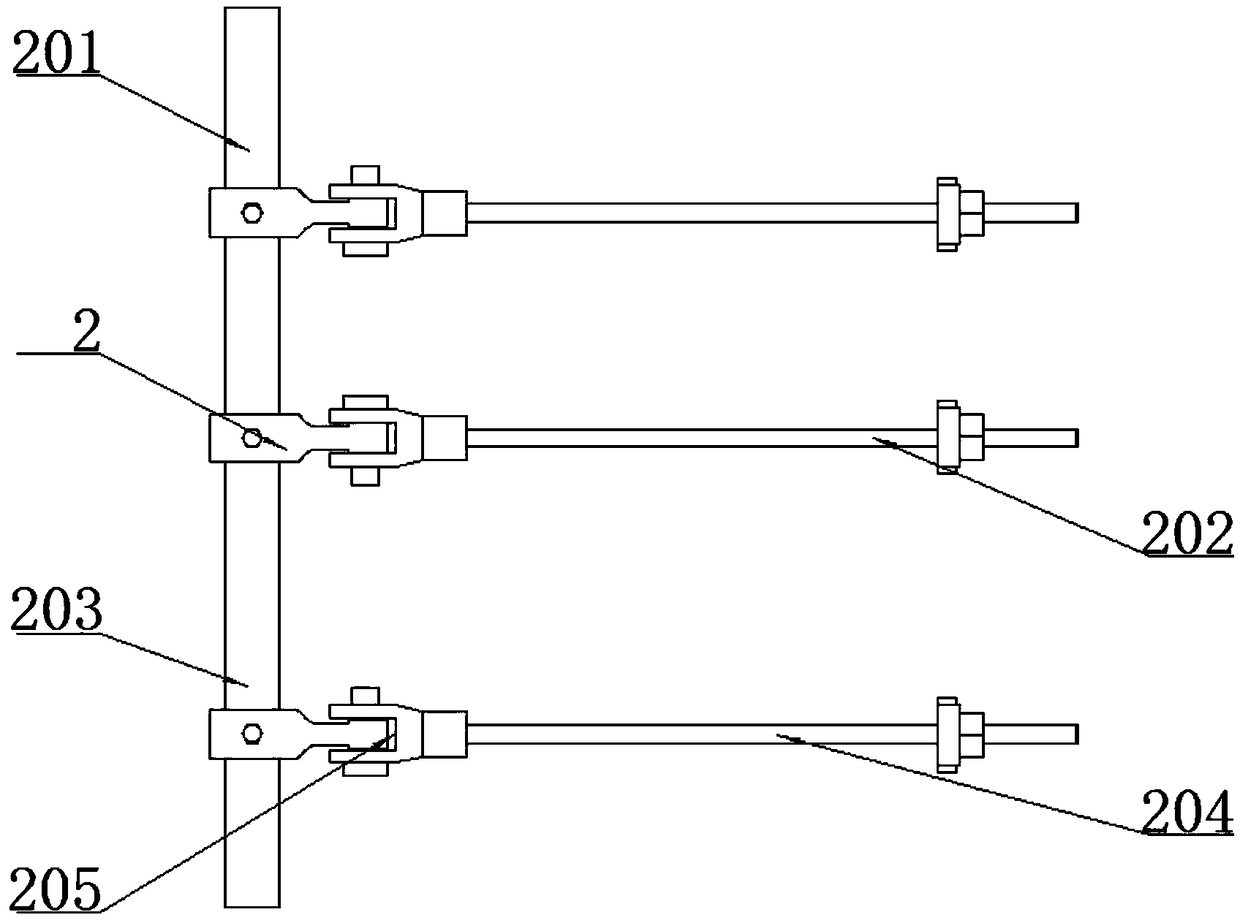

[0019] Such as Figure 1-4Said, is a kind of prestressed co-linear production line for producing concrete slabs and concrete beams, including a working platform 1 for solidifying concrete beams or concrete slabs, and the working platform 1 includes a plurality of longitudinal concrete poured on the ground Beams 101, each concrete longitudinal beam 101 is fixed with a vertical embedded steel plate 102, the upper end of each embedded steel plate 102 extends outside the concrete longitudinal beam 101 and is on the same level as the upper surface of the concrete longitudinal beam 101, and the concrete A horizontal concrete beam 103 is fixed between the longitudinal beams 101, and a pre-embedded steel beam 104 along the length direction of the concrete beam 103 is fixed inside the concrete beam 103, and an edge of the pre-embedded steel beam 104 is exposed to the outside of the concrete beam 103 and the concrete longitudinal beam 103. The upper surface of the beam 101 is flat, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com