Lightweight mechanical arm and robot with same

A mechanical arm, lightweight technology, applied in the field of robotics, can solve the problems of small self-weight-to-load ratio, difficult disassembly and maintenance, heavy weight, etc., to achieve rapid replacement and installation, improve load-to-weight ratio, and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

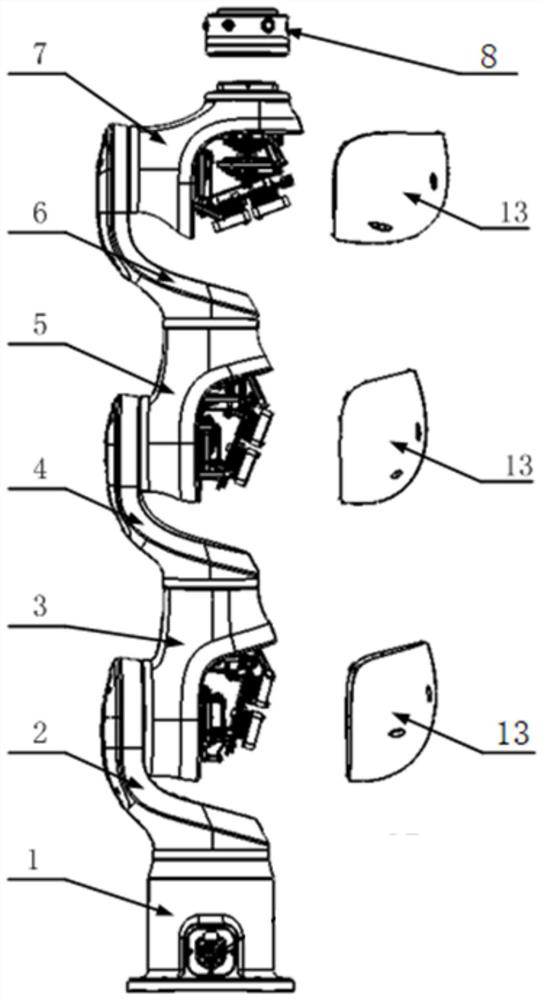

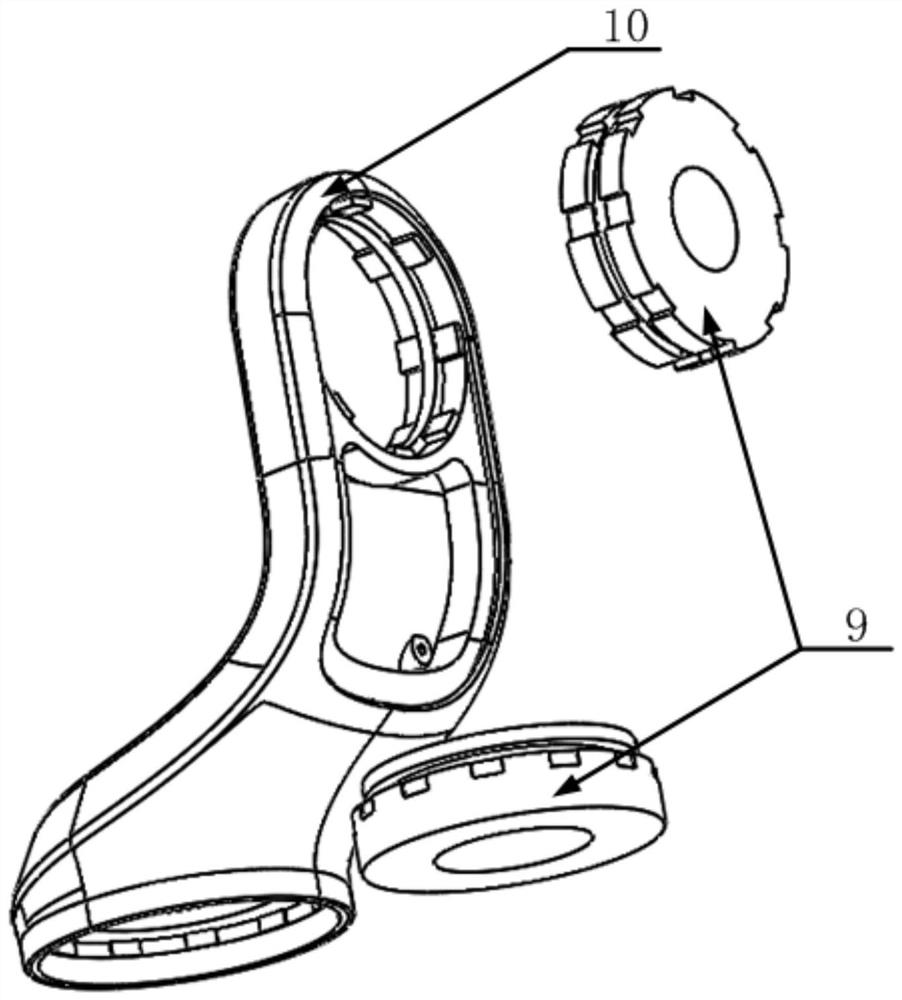

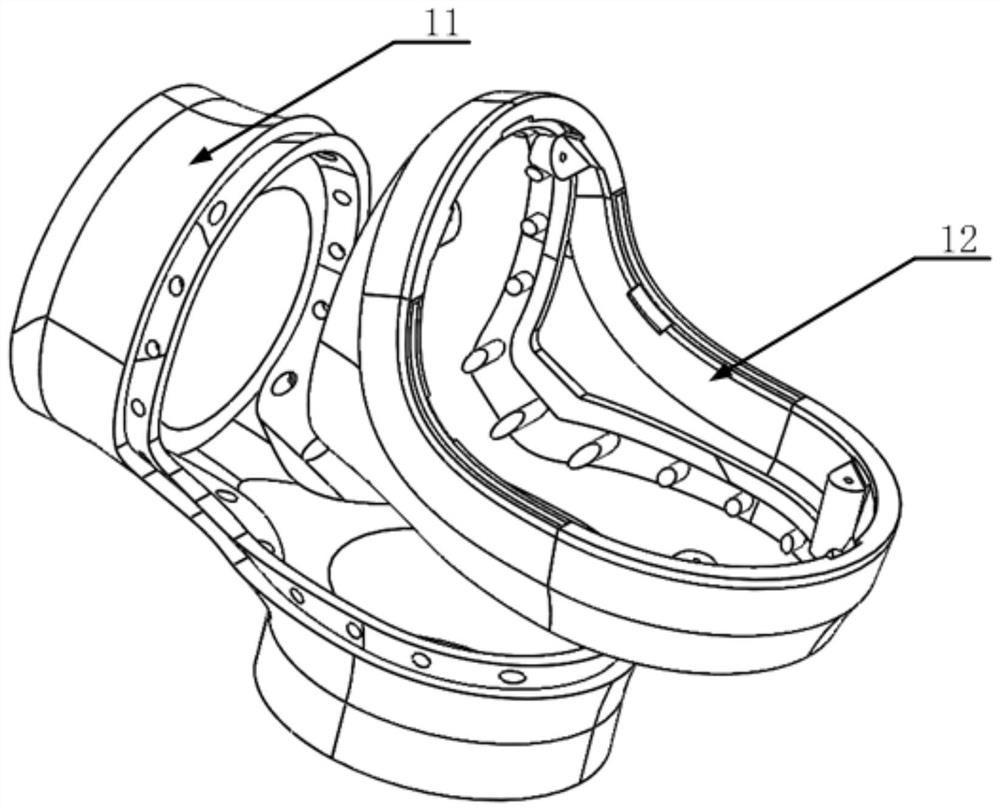

[0044] figure 1 For the structural schematic diagram of the lightweight mechanical arm provided by the embodiment of the present invention, please refer to figure 1 As shown, the lightweight mechanical arm of this embodiment includes a base 1, a first arm body 2, a second arm body 3, a third arm body 4, a fourth arm body 5, a fifth arm body 6, and a sixth arm body 7. The end effector 8, the first modular joint, the second modular joint, the third modular joint, the fourth modular joint, the fifth modular joint, the sixth modular joint, and the seventh modular joint, The first modular joint, the second modular joint, the third modular joint, the fourth modular joint, the fifth modular joint, the sixth modular joint and the seventh modular joint all have rotational degrees of freedom, so The base, the second arm 3, the fourth arm 5, and the sixth arm 7 all have hollow cavities, the first modular joint is located in the hollow cavity of the base 1, and the second modular joint ...

Embodiment 2

[0058] This embodiment provides a robot, which includes the light-weight mechanical arm described in Embodiment 1.

[0059] The light-weight mechanical arm of the robot in this embodiment uses the first modular joint, the second modular joint, the third modular joint, the fourth modular joint, the fifth modular joint, the sixth modular joint and the seventh modular joint The modular joints are arranged in the hollow cavity of the second arm, the fourth arm and the sixth arm, which reduces the overall weight of the mechanical arm and improves the load and self-weight ratio of the mechanical arm. The modular joints are self-contained and can be Direct overall disassembly and assembly avoids the limitation of the outer frame size constraints when installing joint parts in the traditional way, which is conducive to quick replacement and installation, and is also convenient for maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com