Robot for cleaning solar panel

A technology of solar panels and robots, applied in the field of robots, can solve the problems of weakened cleaning effect, incomplete and insufficient cleaning, etc., and achieve the effect of simple structure, small modification and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

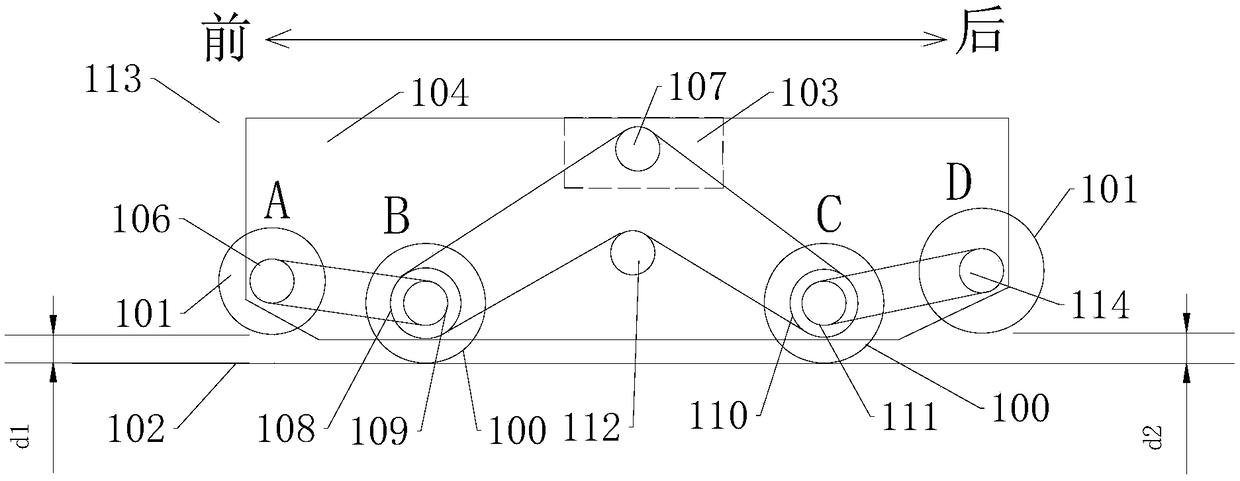

[0048] Such as Figure 1-6 As shown, a robot for cleaning solar panels includes a robot body 113 and a plane walking mechanism and a climbing mechanism arranged on the robot body 113. The plane walking mechanism is used to drive the robot body 113 to move on the solar panel. The mechanism is used to assist the robot body 113 in climbing.

[0049] When solar panels are installed, sometimes there will be a certain height difference at the docking position of adjacent solar panels. When the robot walks to this position, it cannot climb from a low position to a high position, causing the robot to be unable to move forward. By setting up a climbing mechanism, the auxiliary plane The walking mechanism makes the robot climb from the lower solar panel to the higher solar panel, so that the robot can move forward more smoothly.

[0050] The planar traveling mechanism can be a wheeled planar traveling mechanism, or a crawler-type planar traveling mechanism. The crawler-type plane walk...

Embodiment 2

[0052] Such as Figure 1-3 As shown, this embodiment is a further limitation to Embodiment 1, and the planar traveling mechanism in this implementation is a wheeled planar traveling mechanism.

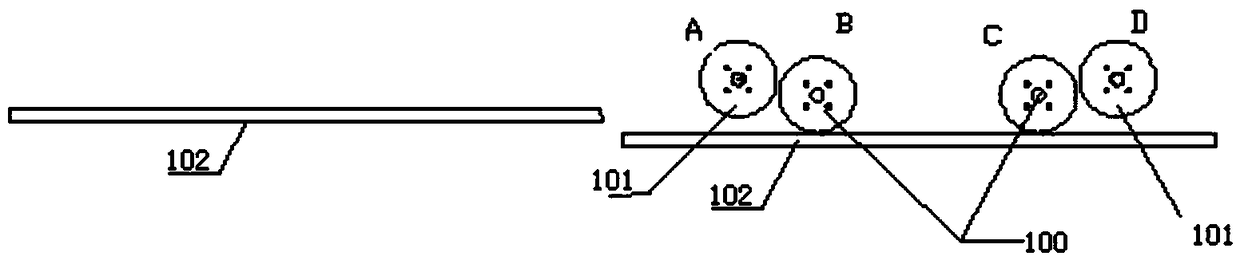

[0053] The plane walking mechanism includes a plurality of walking wheels 100, and the climbing mechanism includes climbing wheels 101. When the robot walks on a plane, the walking wheels 100 contact the walking plane 102, and the lower end of the climbing wheels 101 is spaced from the walking plane 102 by a certain distance. Distance d, when climbing, the climbing wheel 101 is in contact with the slope.

[0054] In the above structure, if the climbing wheel 101 is not provided, when the robot walks between two solar panels with a height difference, the walking wheel 100 will often slip and cannot move forward. By setting the climbing wheel 101, when climbing, the robot can climb The slope wheel 101 is in contact with the slope surface and rotates relatively, so that the front end of ...

Embodiment 3

[0083] Such as Figure 1-3 As shown, a robot for cleaning solar panels includes a robot body 113, a plane walking mechanism, a climbing mechanism and a first driving device, the first driving device includes a drive motor, and the robot body 113 includes a left mounting plate 104 and a right The mounting plate 105, the left mounting plate 104 and the right mounting plate 105 are perpendicular to the walking plane 102, and the left mounting plate 104 and the right mounting plate 105 are all parallel to the walking direction of the robot. The robot body 113 is left-right symmetrical about a mid-plane passing through its midpoint, parallel to the walking direction and perpendicular to the walking plane 102 .

[0084] Such as figure 1 As shown, the planar traveling mechanism includes a traveling wheel 100B, a traveling wheel 100C, a traveling wheel 100B', and a traveling wheel 100C'. The traveling wheel 100B and the traveling wheel 100C are installed on the inner side of the left...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com