A permanent magnet motor with long service life

A permanent magnet motor, long-life technology, used in synchronous motors with static armatures and rotating magnets, electrical components, electromechanical devices, etc. Reduce overheating damage, increase service life and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

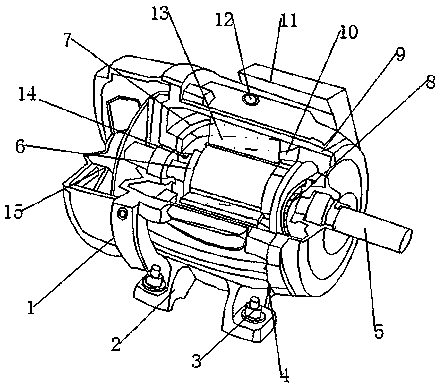

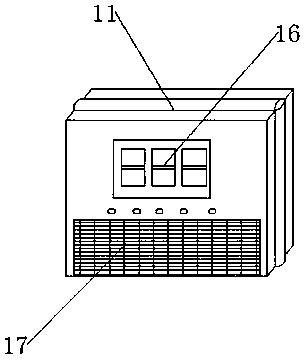

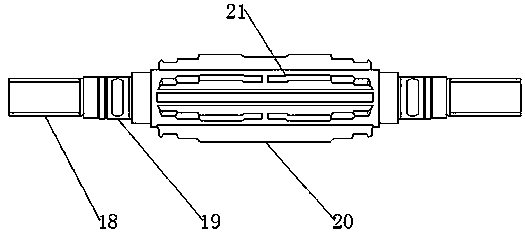

[0022] see Figure 1-3 , The present invention provides a technical solution: a permanent magnet motor with a long service life, comprising a motor body 1, a motor support 2, a fixing bolt 3, a motor casing 4, a motor shaft 5, a rotor 6, a stator 7, a buffer cushion 8. Oil tank 9, built-in monitor 10, motor protector 11, oil filling hole 12, permanent magnet magnetic stage 13, built-in oil pipe 14, cooling fan 15, display panel 16, alarm 17, tandem shaft section 18, bearing support point 19. The motor shaft 20 and the oil passage 21, the outer side of the motor body 1 is provided with a motor housing 4, the bottom end of the motor housing 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com