Preparation method of a lithium ion battery for improving the comprehensive performance of a high-voltage cathode material

A technology for lithium ion batteries and cathode materials, applied in electrode manufacturing, electrode collector coating, secondary batteries, etc. Current rate discharge performance and cycle performance, large solid content, and the effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

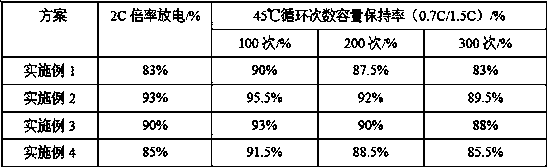

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: what this embodiment records is a kind of preparation method of the lithium-ion battery that improves the comprehensive performance of high-voltage positive electrode material, and the concrete steps of described method are as follows:

[0015] Step 1: Coating a layer of positive electrode slurry A with a thickness of 5um~25um on the positive electrode current collector to form a better conductive coating; the specific configuration method of the positive electrode slurry A is: first add a conductive agent and binder, and finally add the main material of the positive electrode, and the main material of the positive electrode is added in 2 to 5 times on average; (this slurry can be prepared in the production line or in the laboratory)

[0016] Step 2: After the positive electrode slurry A is coated, apply a layer of positive electrode slurry B with a thickness of 150-200um. After the coating is completed, it can be sorted according to the conventi...

specific Embodiment approach 2

[0033] Specific embodiment two: the preparation method of a kind of lithium ion battery that improves the comprehensive performance of high-voltage positive electrode material described in specific embodiment one, in step one, described positive electrode slurry A is made of positive electrode main material, conductive agent, binding agent Agent composition, the positive electrode main material: conductive agent: binder mass ratio = 96.8% ~ 97.2%: 1.3% ~ 1.8%: 1.0% ~ 1.9%.

specific Embodiment approach 3

[0034] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 3 The preparation method of a lithium-ion battery that improves the comprehensive performance of the high-voltage positive electrode material described in the first specific embodiment, in step 2, the positive electrode slurry B is composed of a positive electrode main material, a conductive agent, and a binder Composition, the mass ratio of the positive electrode main material: conductive agent: binder = 96.8%~97.2%: 1.3%~1.8%: 1.0%~1.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com