Method for destressing defective glass product

A glass and defective technology, applied in the direction of glass production, etc., can solve the problems of glass bending deformation, low rework yield, long rework time, etc., to avoid scratches, reduce the difficulty of rework, and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

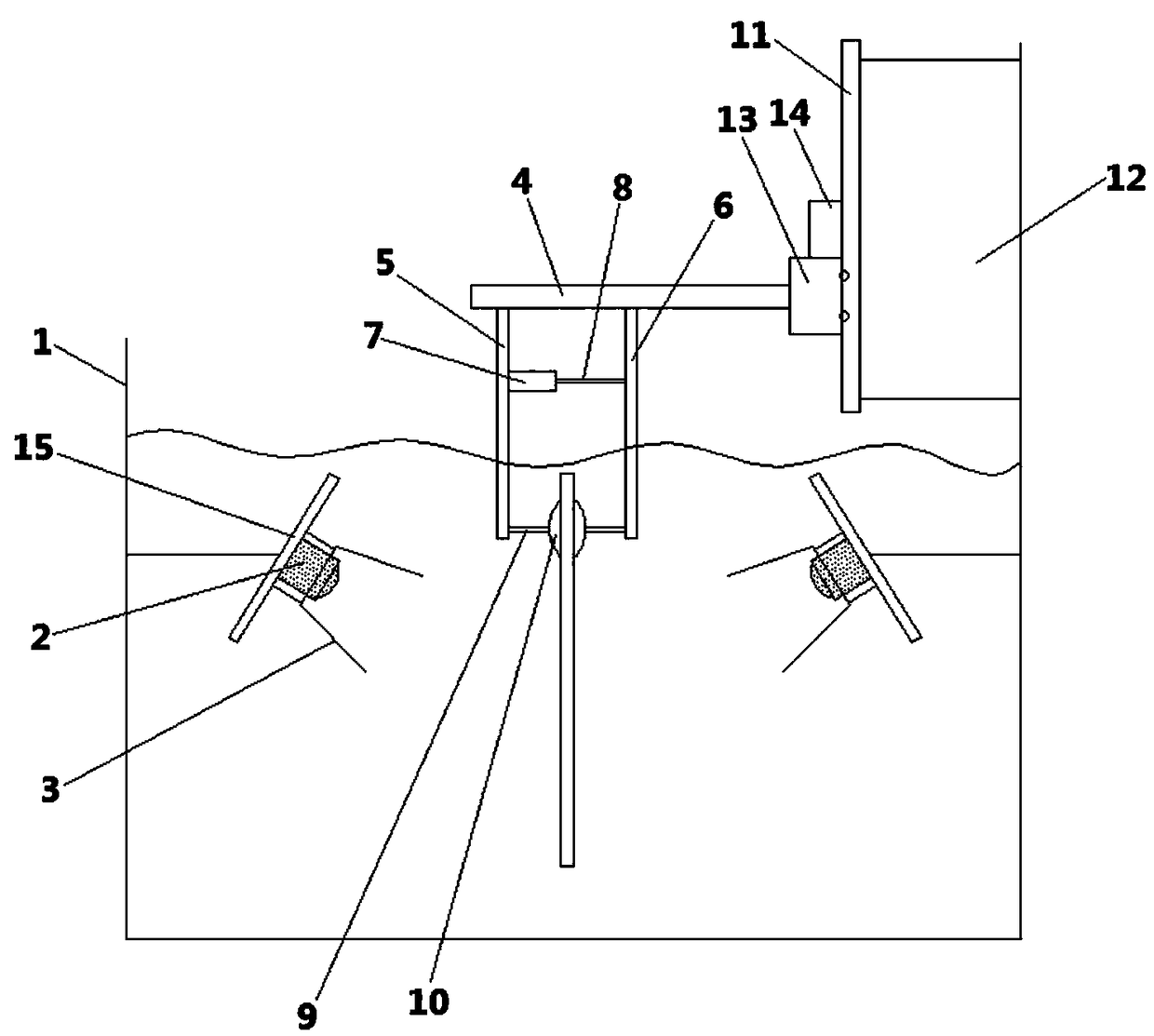

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0030] Such as figure 1 Shown, the present invention provides a kind of method for stress relief of defective glass products, comprising the following steps:

[0031] Step 1. Put the defective glass in the glass deinking agent for 5-8 minutes to remove the ink and film on the glass surface, so that the glass can reach a transparent and colorless state;

[0032] Step 2. Clean the deinked transparent glass with ultrasonic waves to remove the dirt layer on the surface.

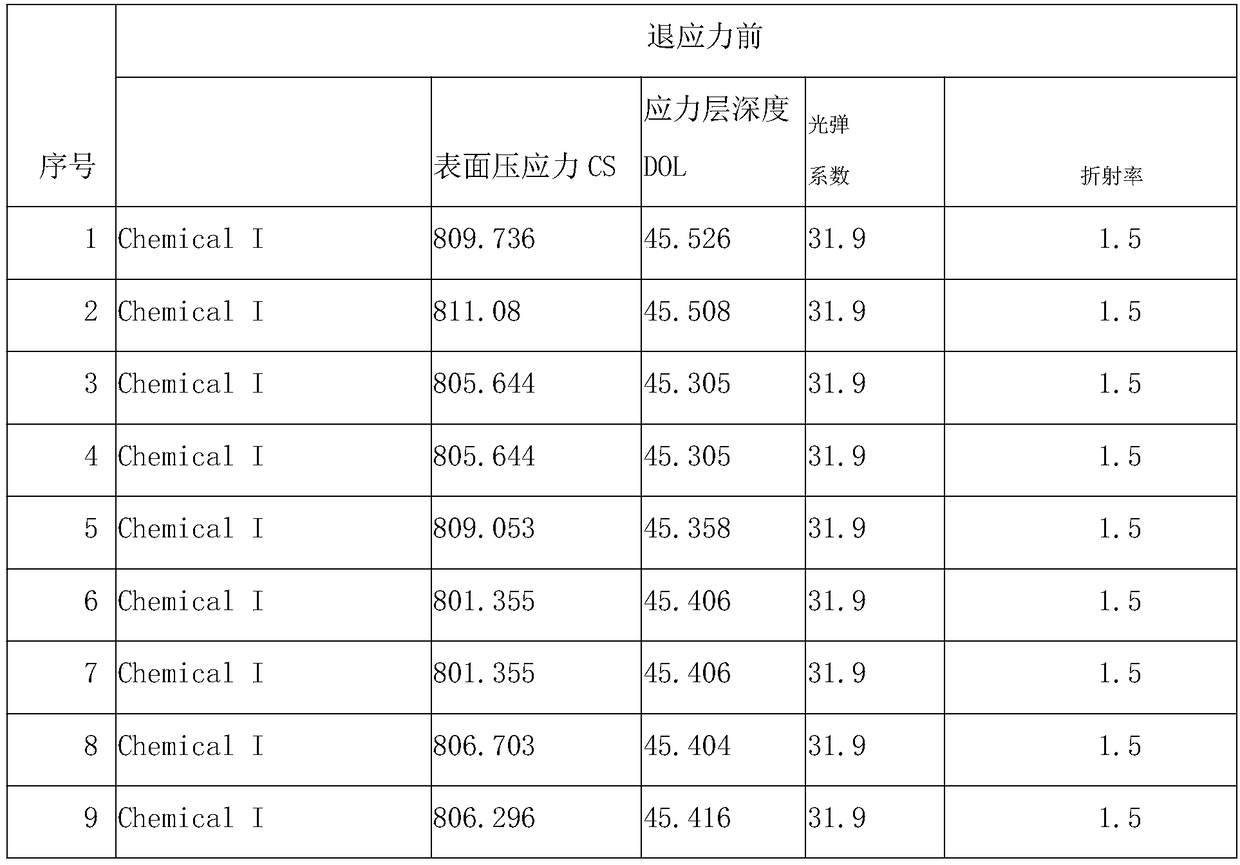

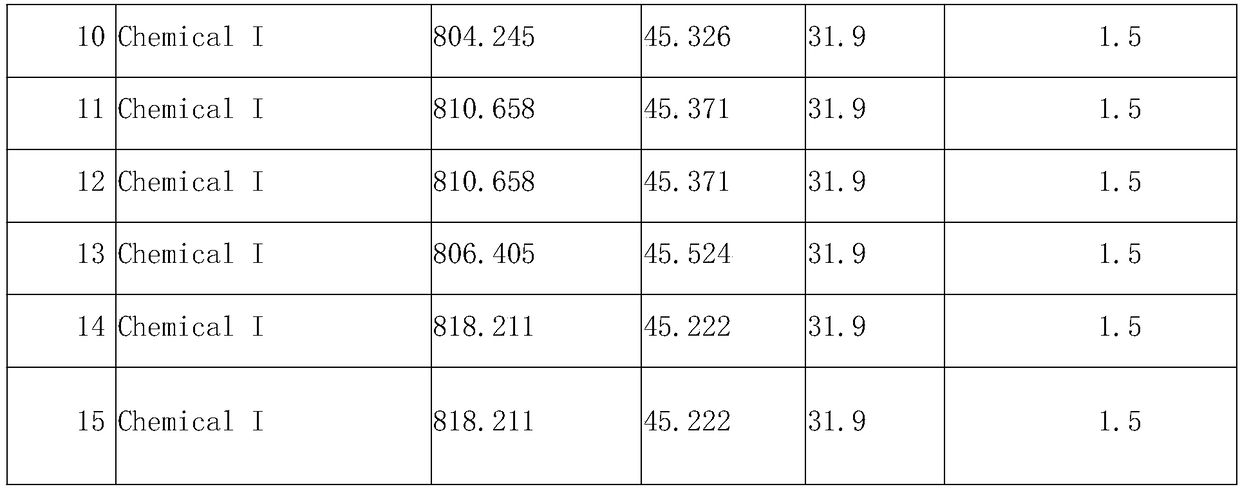

[0033] Step 3: Place the cleaned glass in a high-concentration sodium salt melt to replace the potassium ions in the glass, thereby eliminating the compressive stress on the surface due to the presence of potassium ions and restoring the glass to a stress-free state. The sodium salt is high-purity sodium nitra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com