Automatic reeling equipment

A roll material, automatic technology, applied in the direction of coiling strips, thin material processing, transportation and packaging, etc., can solve the problems of low efficiency and high labor intensity of workers, and achieve high connection strength, simple structure, reasonable and compact layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

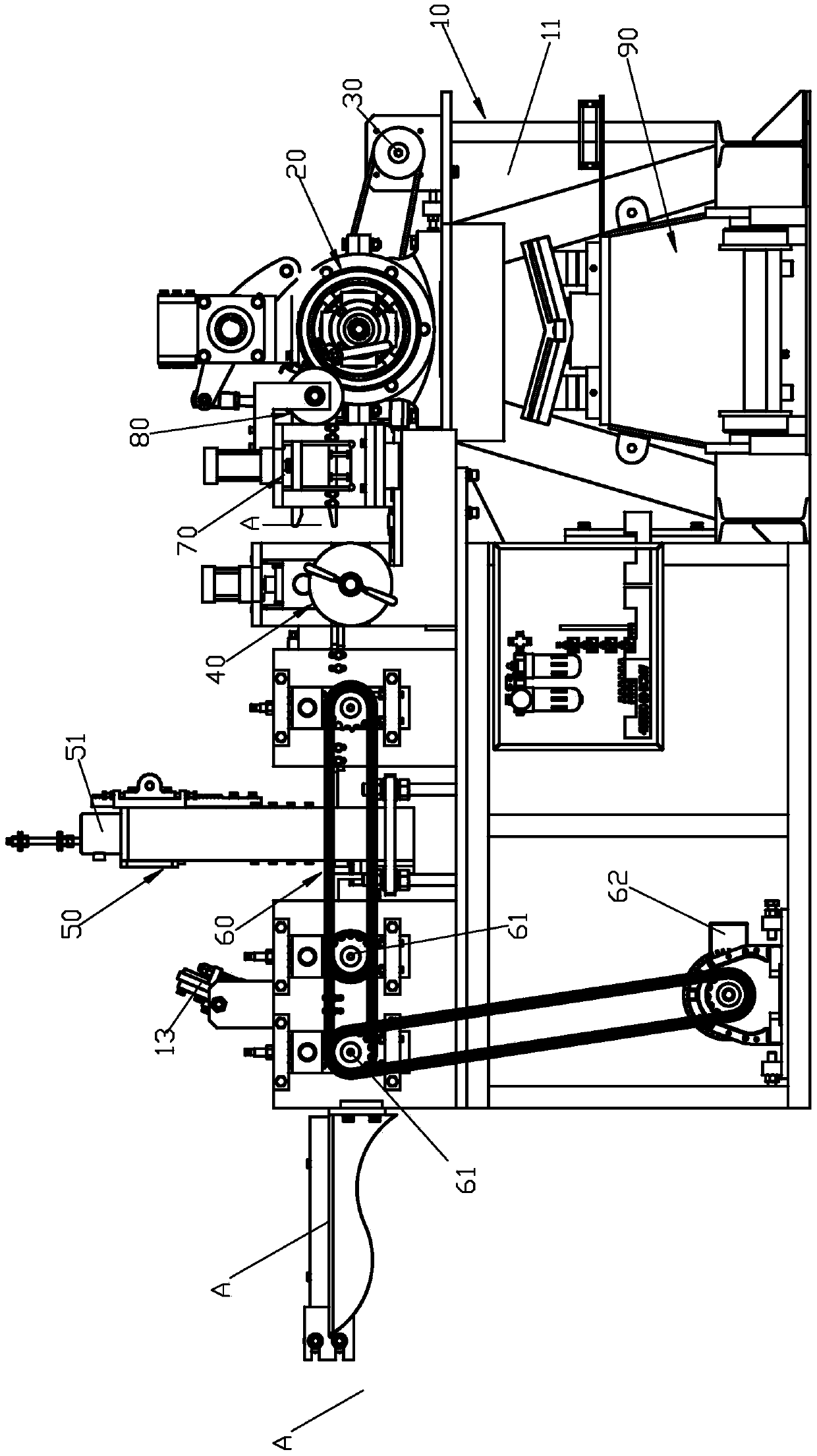

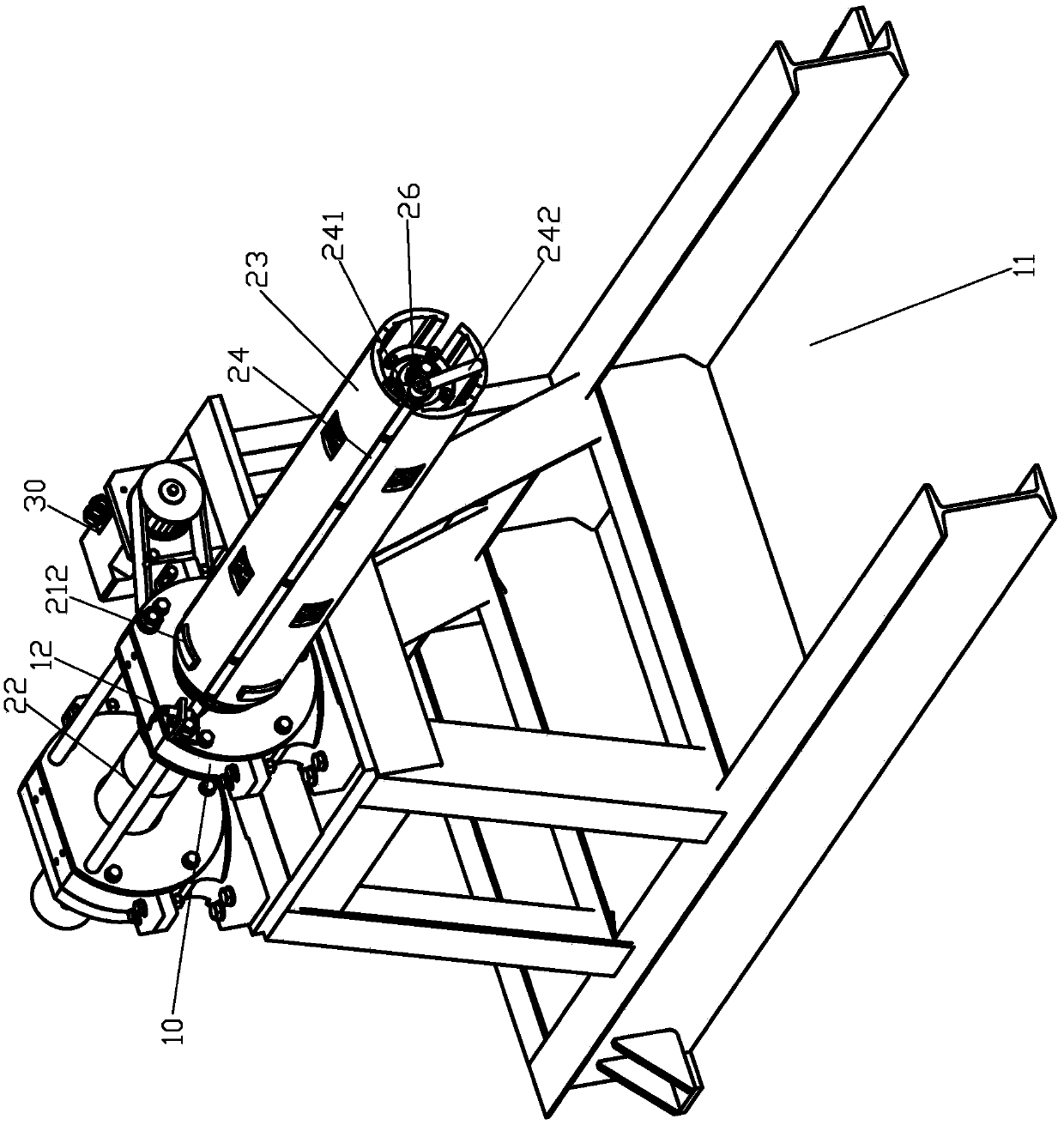

[0040] Please check Figure 1 to Figure 10 , automatic coiling equipment, including a frame 10, a coiling device, a first driver 30, a tensioning mechanism 40, a shearing mechanism 50, and a conveying mechanism 60. The coiling device includes a coiling mechanism 20 , a material leading device 70 and a guiding device 80 .

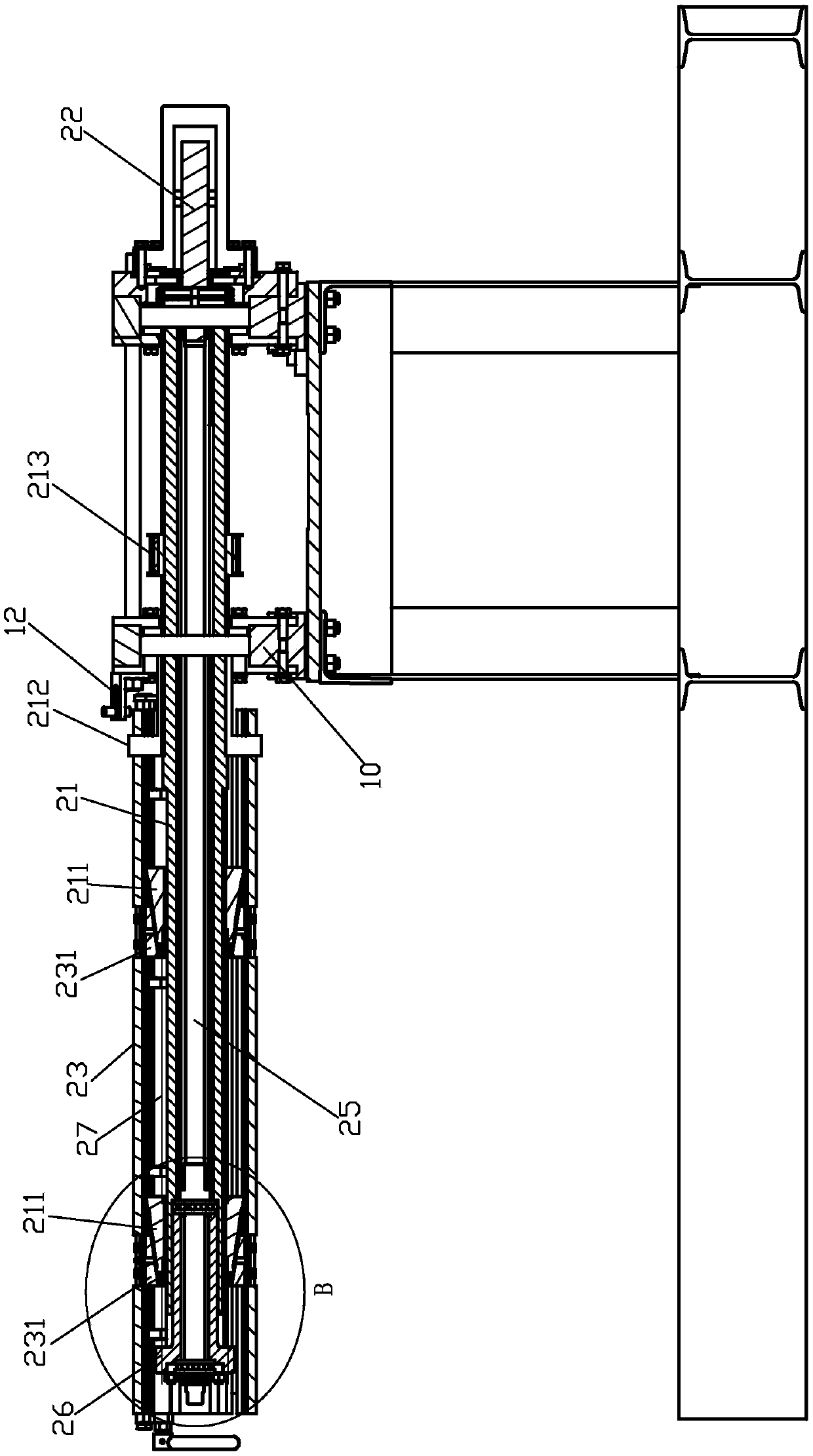

[0041] The coil mechanism 20 includes a support shaft 25, a rotating part, a second driver 22 and a clamping head mechanism. The rotating part includes a main shaft 21 and a plurality of circular arrays arranged at intervals around the main shaft 21 and capable of radially moving relative to the main shaft 21. part 23, the movable part 23 is an arc-shaped plate; the main shaft 21 is rotatably mounted on the frame 10 and rotatably sleeved outside the support shaft 25; the movable part 23 and the main shaft 21 form a synchronous The rotating and movable part 23 can be connected radially relative to the main shaft 21 . The first driver 30 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com