Concrete mixer with filtering function

A concrete mixer, functional technology, applied in the direction of cement mixing device, clay preparation device, mixing operation control, etc., can solve the problems of not having raw material filtration, uneven mixing, increased mixing volume, etc., to achieve fast and convenient buffering and shock absorption, fast Easy to filter and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

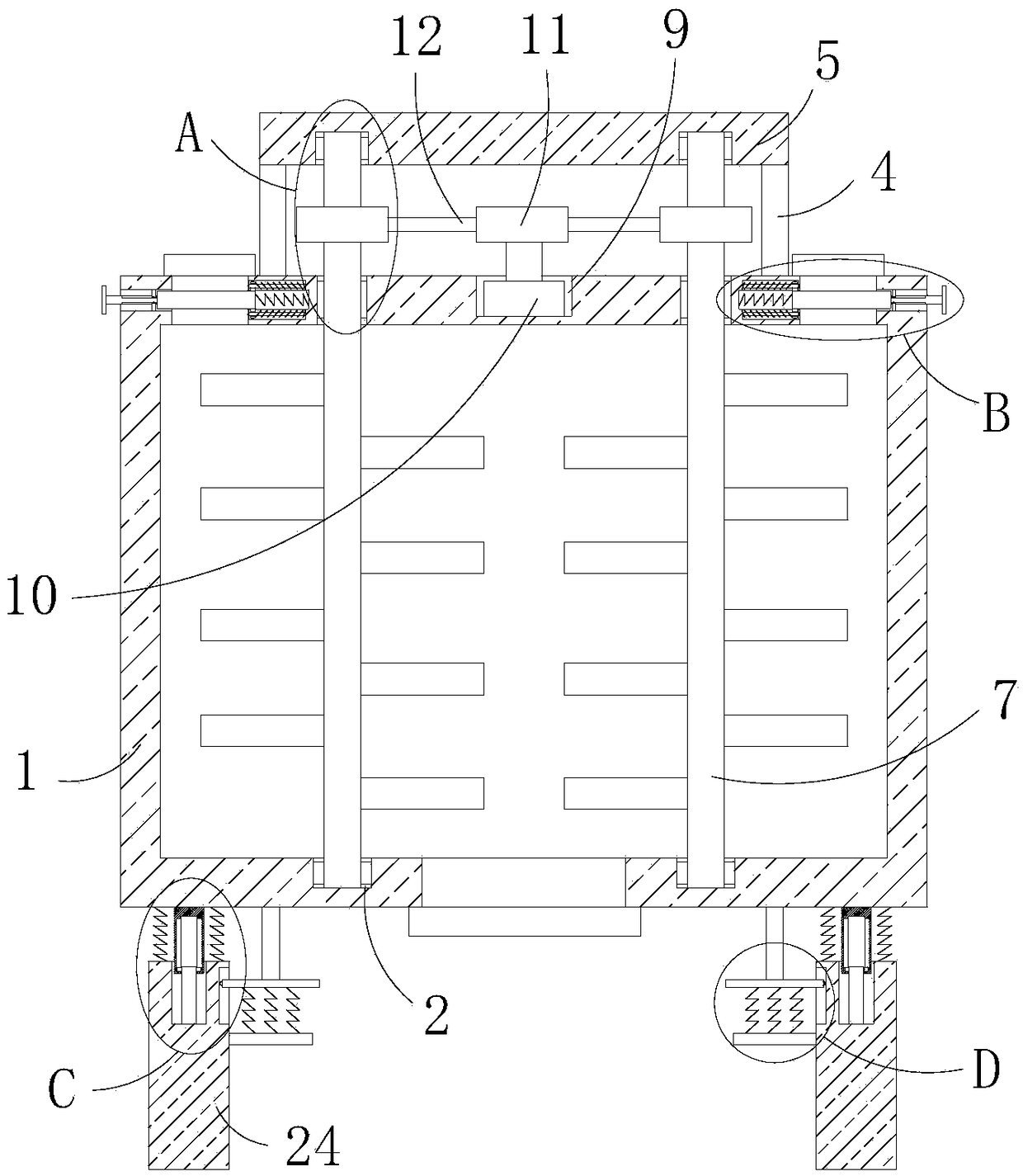

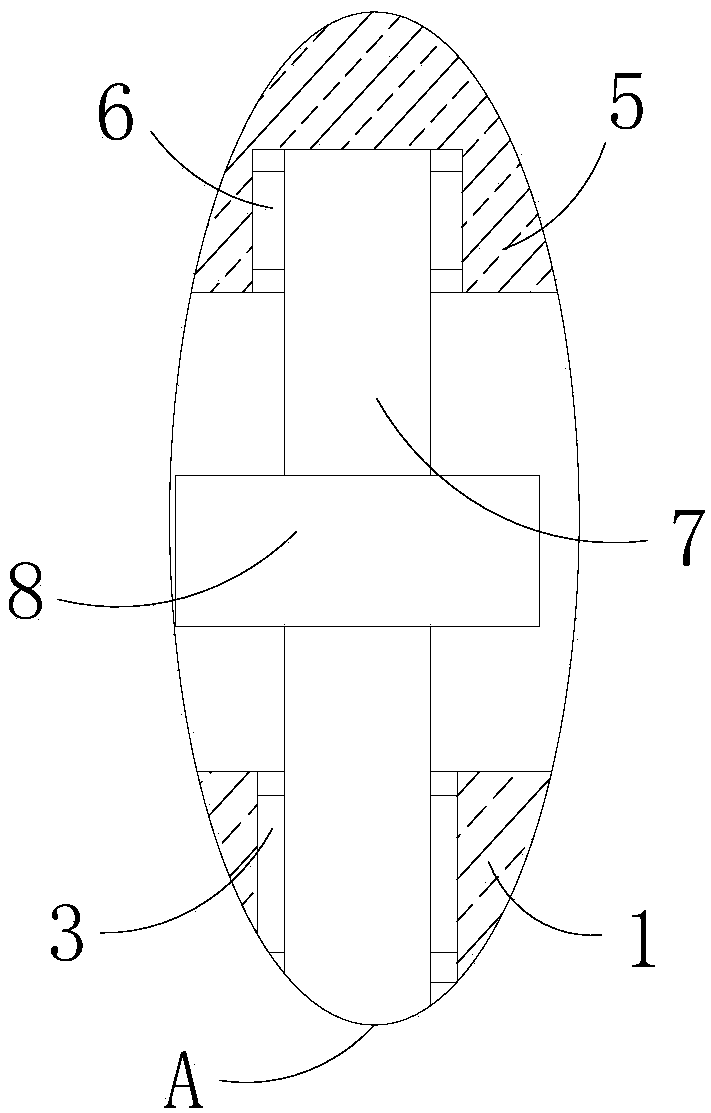

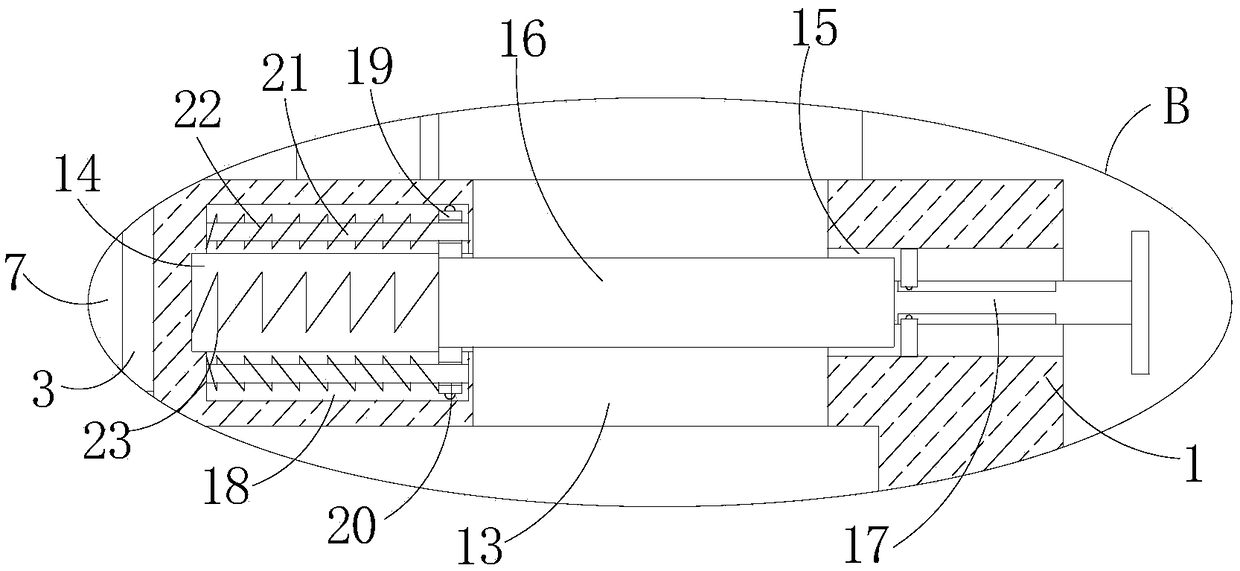

[0024] refer to Figure 1-5, a concrete mixer with filtering function is proposed in the present embodiment, comprising a mixing box 1 set as a hollow structure, two first rotating grooves 2 are provided on the bottom inner wall of the mixing box 1, and the top of the mixing box 1 is provided with Two rotating holes 3, fixed rods 4 are fixedly installed on both sides of the top of the mixing box 1, the top of the two fixed rods 4 is fixedly installed with the same fixed plate 5, and the bottom of the fixed plate 5 is provided with two second rotating slots 6, and the second rotating groove 6, the rotating hole 3 and the first rotating groove 2 are installed with the same rotating column 7, and the outer sides of the two rotating columns 7 are fixedly installed with the first sprocket 8 above the mixing box 1 , the top of the mixing box 1 is provided with a motor placement slot 9, a stepper motor 10 is fixedly installed in the motor placement slot 9, a second sprocket 11 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com