Low-temperature, sulfur-resistant phosphorus-containing cerium-iron-tin composite denitrification catalyst and preparation method thereof

A denitrification catalyst, ferrocerium technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of catalyst deactivation, low-temperature denitrification efficiency, poor catalytic activity, etc., and achieve simple preparation methods, Excellent low-temperature catalytic activity and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

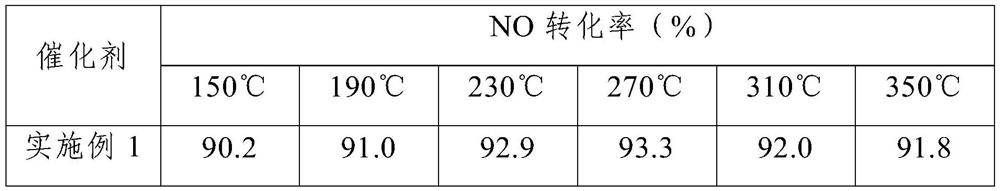

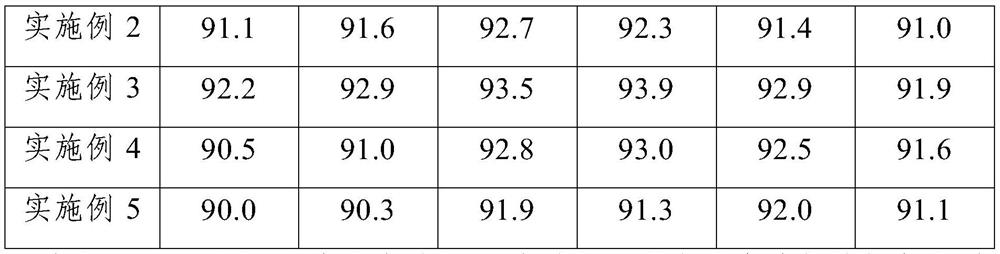

[0023]The phosphorus-containing tin composite denitrification catalyst containing cerium is composed of a phosphate, iron oxide and tin oxide, and the mass ratio of iron oxide and tin oxide is 1: 0.2: 0.03; The nitrogen oxide conversion of the phosphorus-containing iron-containing iron-containing composite denitration catalyst at a temperature condition of 150 ° C to 350 ° C reaches 90% or more.

[0024]The preparation method of the phosphorus-containing tin composite denitrifination catalyst containing the present embodiment includes the steps of:

[0025]Step 1, 6.51 g of six-water nitrate is dissolved in 100 g of deionized water, then mixed into aqueous pyrophosphate aqueous solution, mixed well, to obtain a mixed solution A; the aqueous pyrophosphate solution is dissolved from 0.89 g of pyrophosphate in 100 g of water formulation get;

[0026]Step 2, 6.00 g of urea added to the mixed solution A obtained in the steps of the mixing solution A to all dissolved to give a mixed solution B, an...

Embodiment 2

[0030]The phosphorus-containing tin composite denitrification catalyst containing cerium is composed of a phosphate, iron oxide and tin oxide, and the mass ratio of iron oxide and tin oxide is 1: 0.2: 0.04; The nitrogen oxide conversion of the phosphorus-containing iron-containing iron-containing composite denitration catalyst at a temperature condition of 150 ° C to 350 ° C reaches 90% or more.

[0031]The preparation method of the phosphorus-containing tin composite denitrifination catalyst containing the present embodiment includes the steps of:

[0032]Step 1, 4.34 g of six-water nitrate is dissolved in 100 g of deionized water, then mixed into aqueous pyrophosphate aqueous solution to mix well, resulting in a mixed solution A; the aqueous pyrophosphate solution is dissolved from 0.89 g of pyrophosphate in 100 g of water formulated get;

[0033]Step 2, 6.00 g of urea was added to the mixed solution A obtained in the step one to completely dissolve the mixed solution B, and then the mixed...

Embodiment 3

[0037]The phosphorus iron-containing iron-containing composite denitration catalyst of this embodiment is composed of a phosphate, iron oxide and tin oxide, and the mass ratio of iron oxide and tin oxide is 1: 0.2: 0.05; The nitrogen oxide conversion of the phosphorus-containing iron-containing iron-containing composite denitration catalyst at a temperature condition of 150 ° C to 350 ° C reaches 90% or more.

[0038]The preparation method of the phosphorus-containing tin composite denitrifination catalyst containing the present embodiment includes the steps of:

[0039]Step 1, 4.34 g of six-water nitrate is dissolved in 100 g of deionized water, then mixed into aqueous pyrophosphate aqueous solution to mix well, resulting in a mixed solution A; the aqueous pyrophosphate solution is dissolved from 0.89 g of pyrophosphate in 100 g of water formulated get;

[0040]Step 2, 6.00 g of urea was added to the mixed solution A obtained in the step 1 to completely dissolve the mixed solution B, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com