A coil pressing device

A compression device and coil technology, which is applied in coil manufacturing and other directions, can solve the problems of time-consuming and labor-intensive installation and inconvenient coil placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. A preferred embodiment of the invention is shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

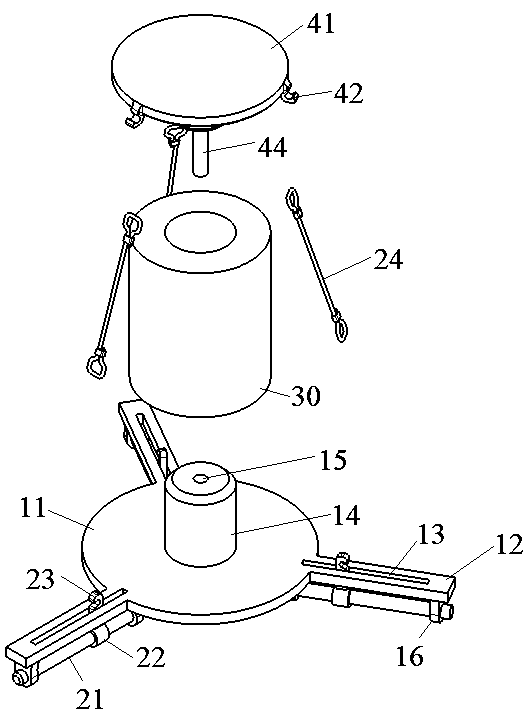

[0020] see Figure 1~Figure 4 The coil pressing device shown includes a supporting part 10, a transmission part 20 and a pressing part 40, the pressing part 40 is installed above the supporting part 10, and the coil 30 is placed between the pressing part 40 and the supporting part 10, and the transmission part 20 The pressing part 40 is pulled downward to realize the pressing effect on the coil 30 .

[0021] The supporting part 10 includes a base 11 , a beam 12 , a slide groove 13 , a lower boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com