Control method for axial process straightening zero correction of straightening roller of shaped steel straightening machine

A technology for straightening and zero-position correction of a straightening machine, which is applied in the directions of comprehensive factory control, comprehensive factory control, program control, etc., which can solve the problems of poor straightening stability of rolling pieces, inability to achieve automatic axial zero position, and extreme influence on straightening quality. Large and other problems, to achieve the effect of high zero correction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

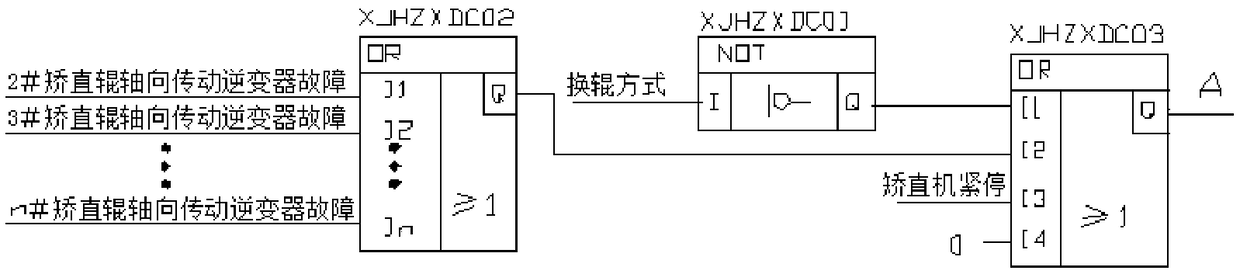

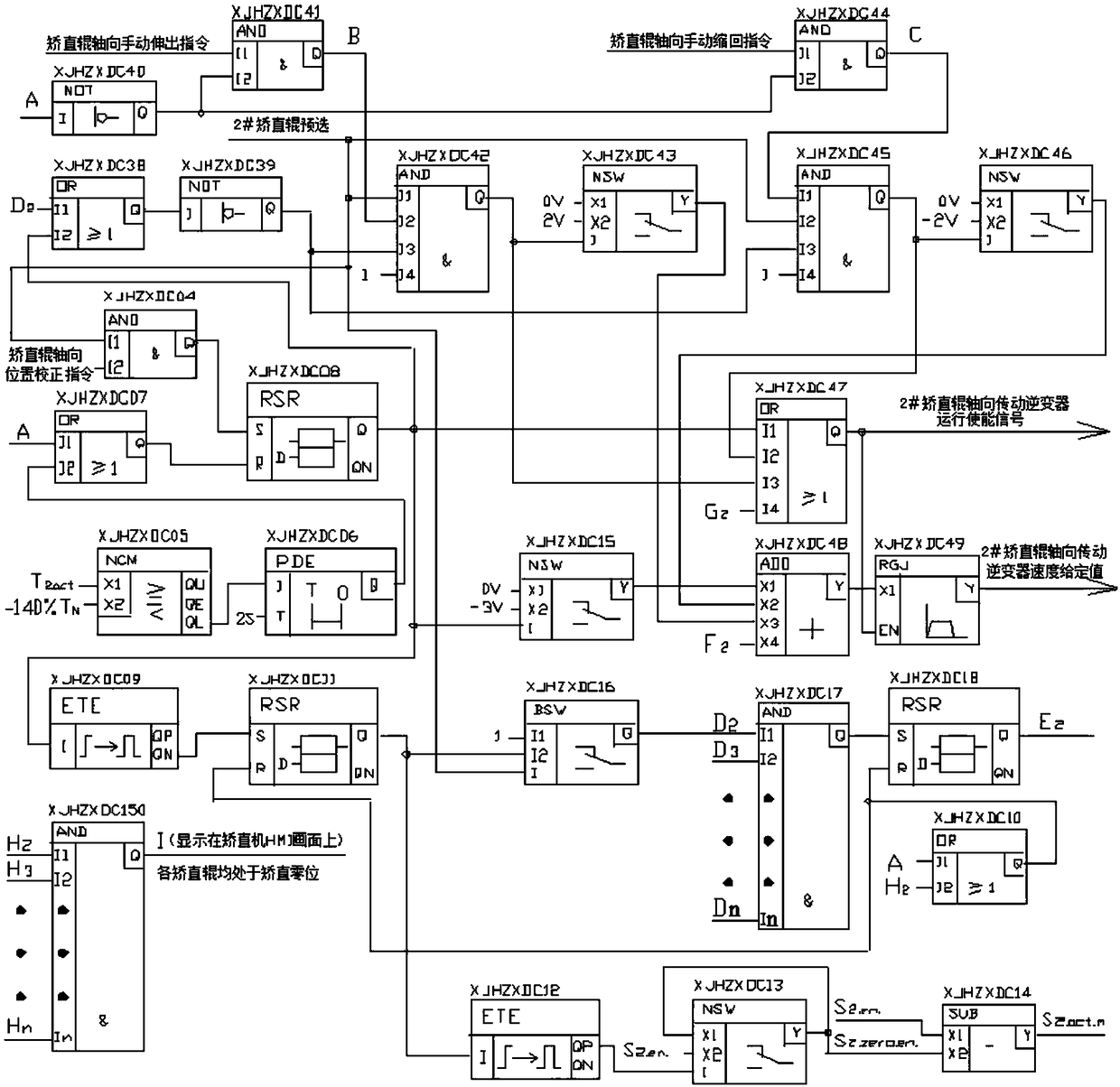

[0042] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0043] Such as figure 1 The structure of the present invention expressed is a section steel straightening machine. The section steel straightening machine includes nine cantilever type straightening rollers, four of which are upper straightening rollers, five are lower straightening rollers, and the upper and lower Arranged in a staggered manner, they are No. 1 straightening roll to No. 9 straightening roll (their numbers are R1 to R9); and N represents any one of No. 3 roll to No. 8 roll.

[0044] Among the nine straightening rollers, except that the axial positions of the R1 and R9 straightening rollers are fixed, the rest of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com